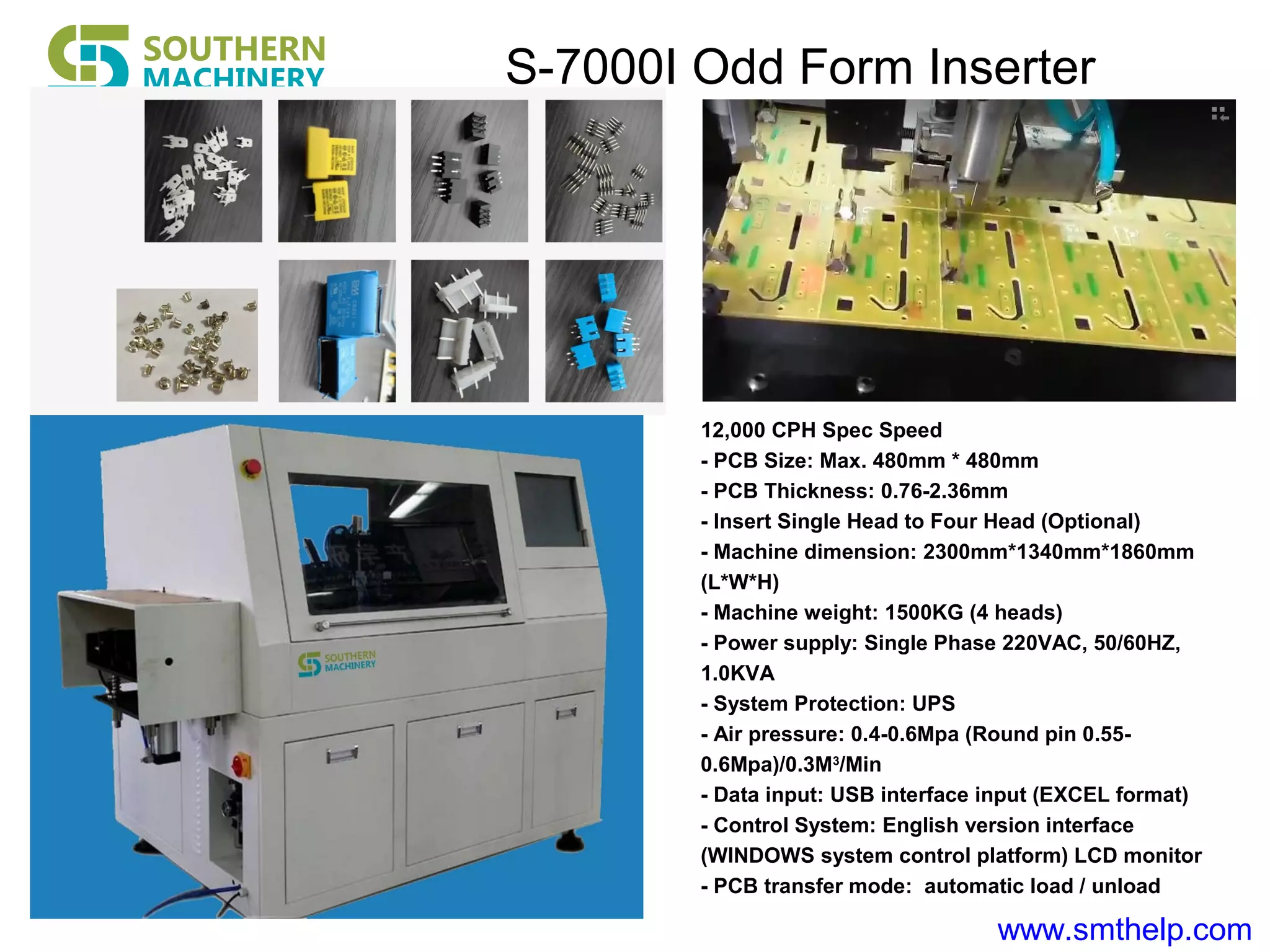

The document provides detailed specifications for various models of SMT (Surface Mount Technology) equipment, including automatic loaders, screen printers, insertion machines, and reflow ovens. Each model is described with dimensions, power requirements, weight, PCB sizes, and other operational features, indicating their applications in electronic manufacturing. It highlights the capabilities of these machines, including speed, accuracy, and customizable settings for efficient production processes.