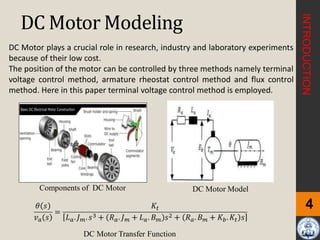

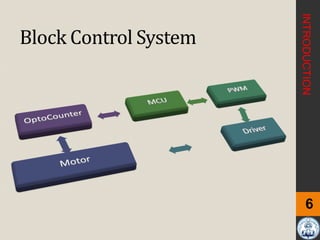

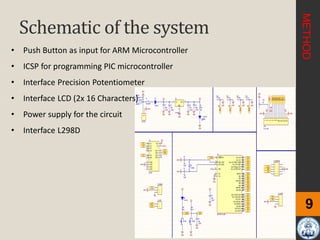

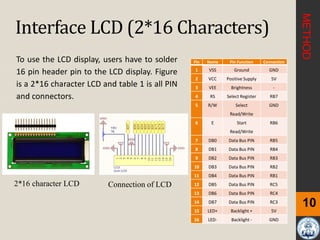

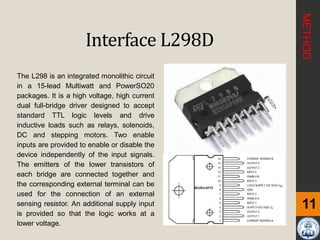

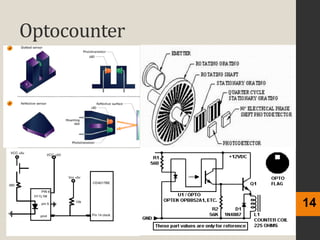

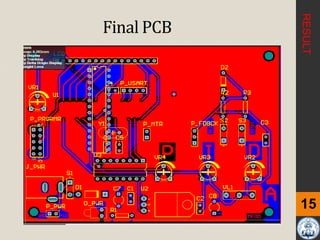

This document summarizes a project to control the speed of a DC motor using an ARM microcontroller. It describes the components used including the ARM microcontroller, motor driver, optocounter, and interfaces to an LCD display. It provides the schematic and code for the motor control system, which implements a PID control loop to control motor speed based on feedback from the optocounter. It also presents the final PCB design and hardware implementation of the DC motor speed control system using an ARM microcontroller.