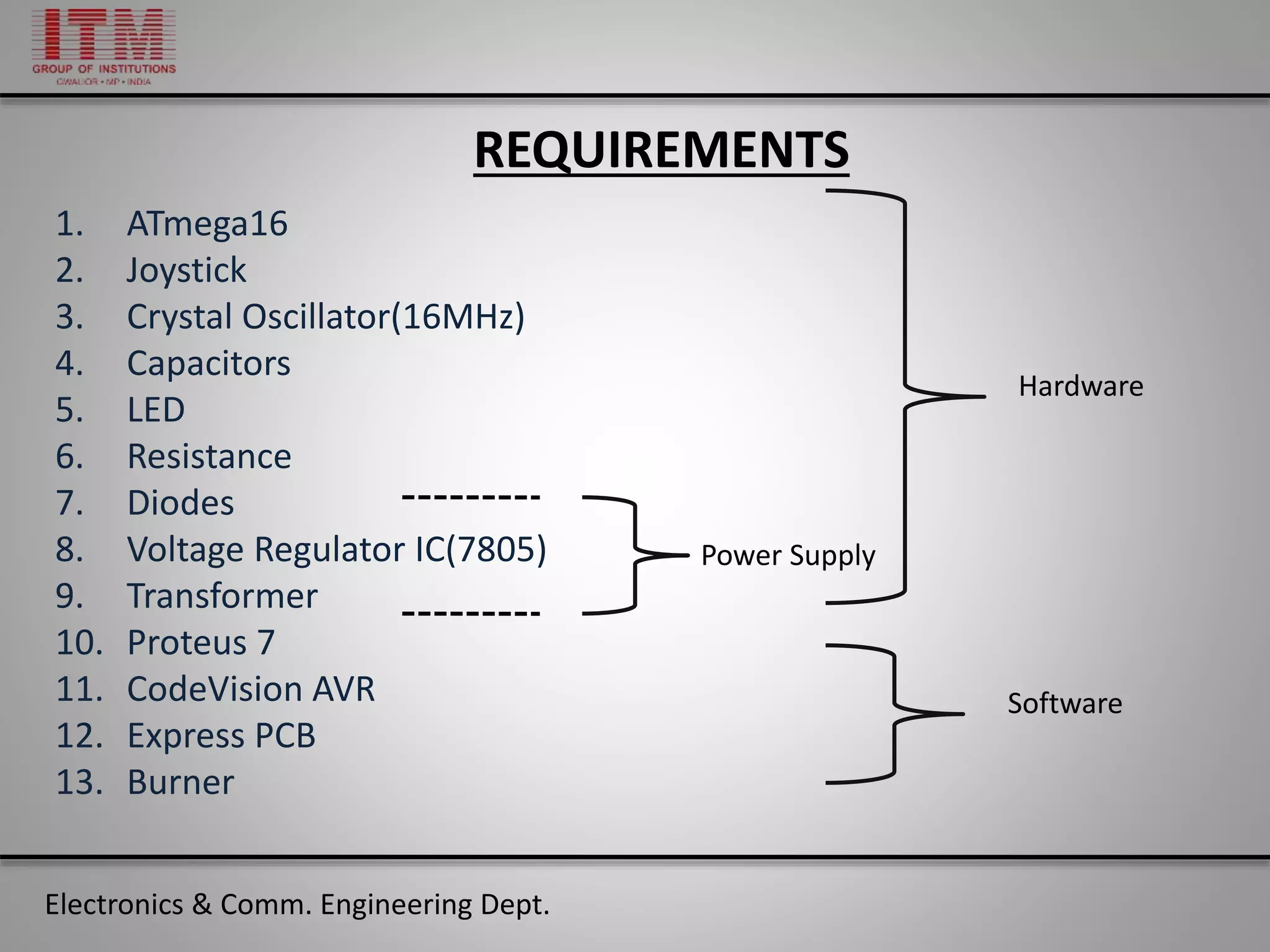

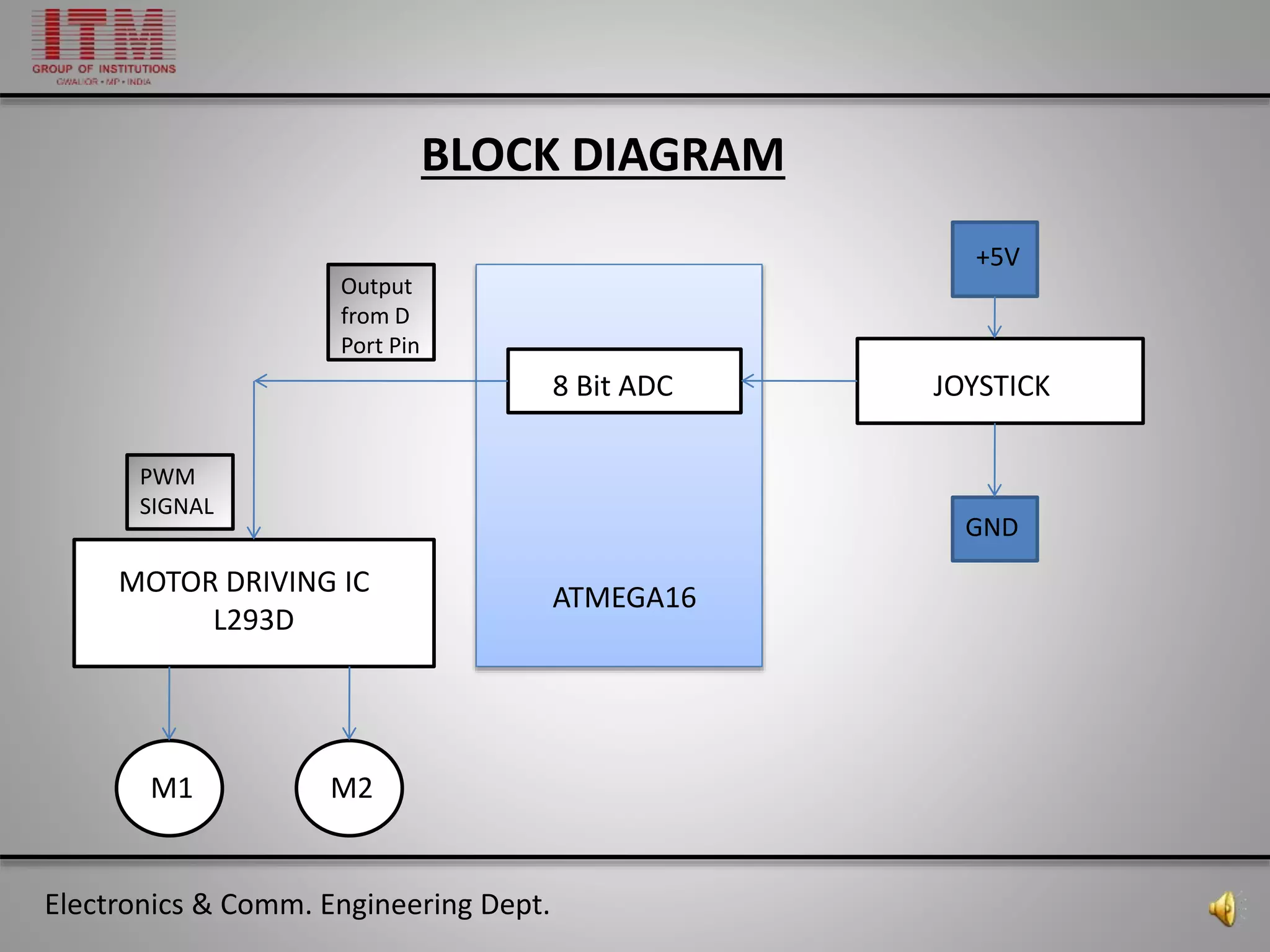

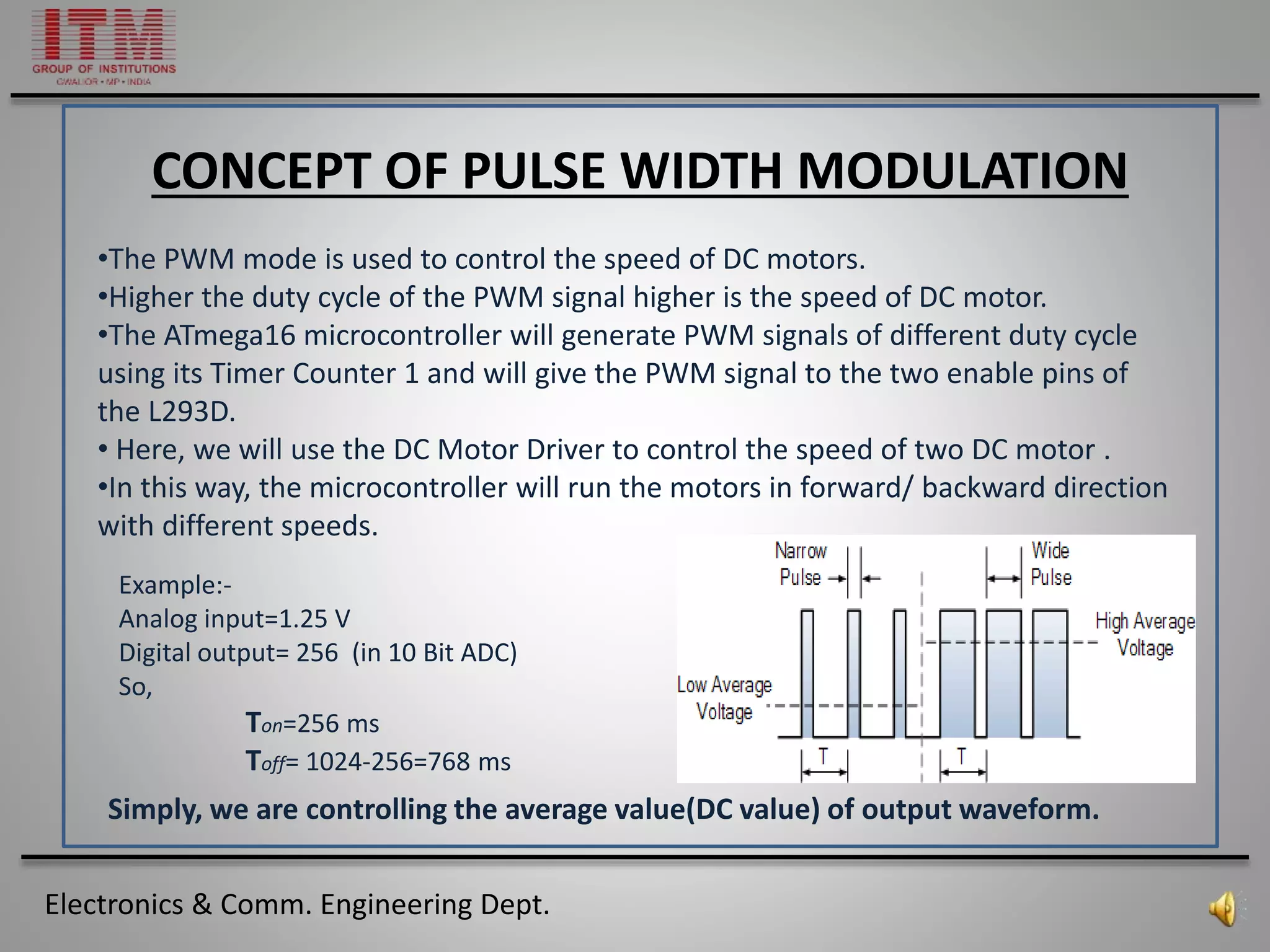

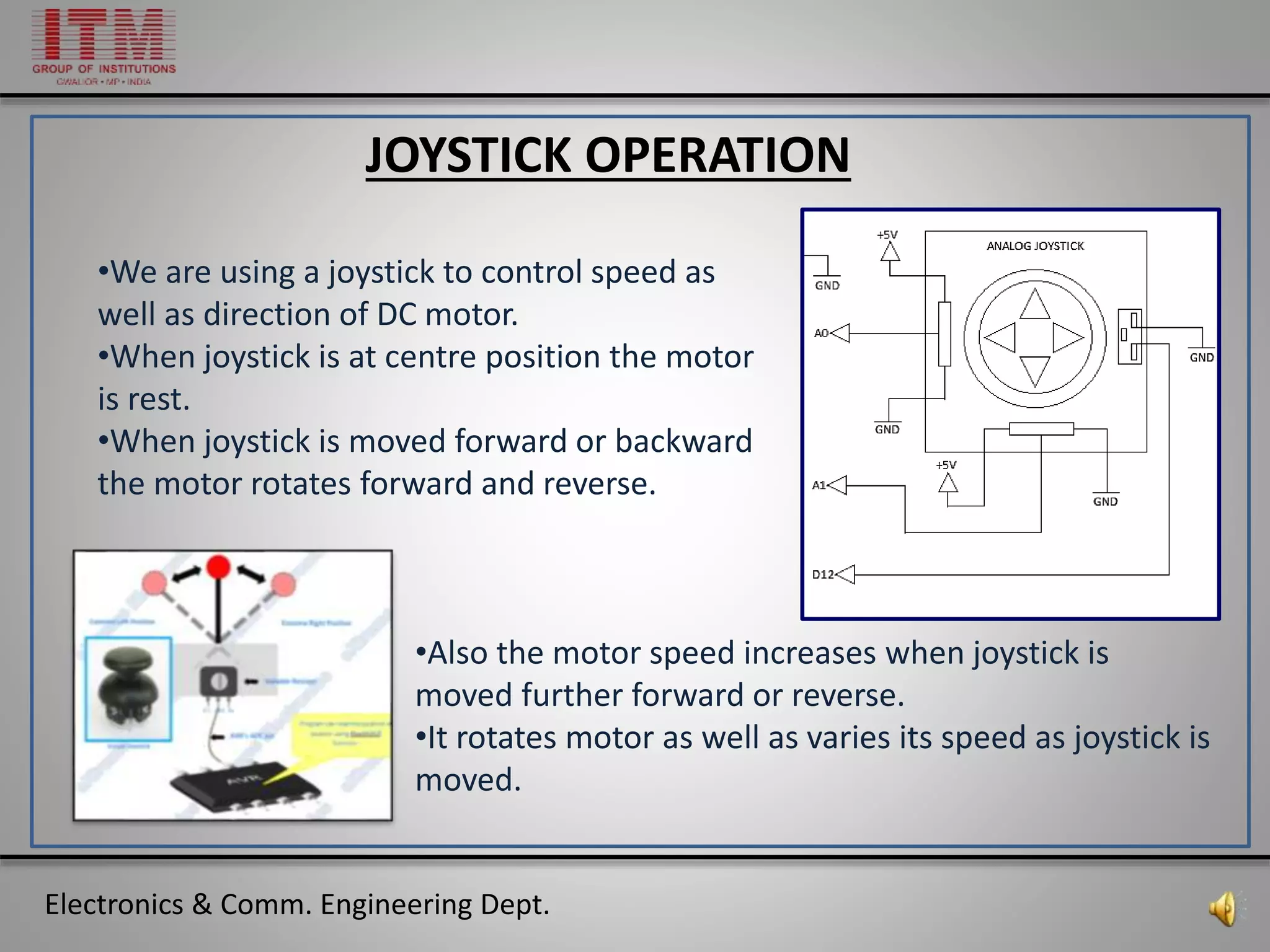

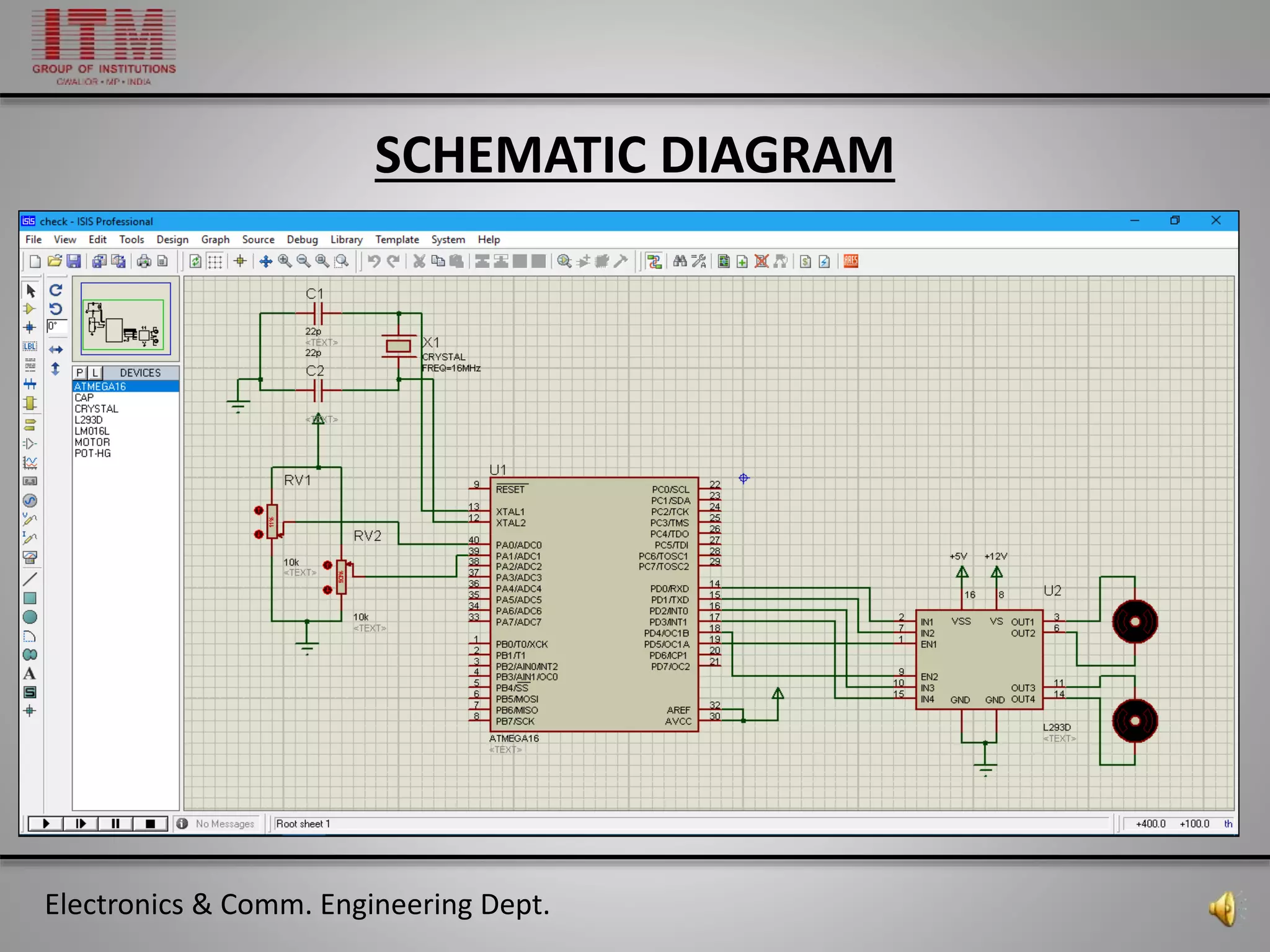

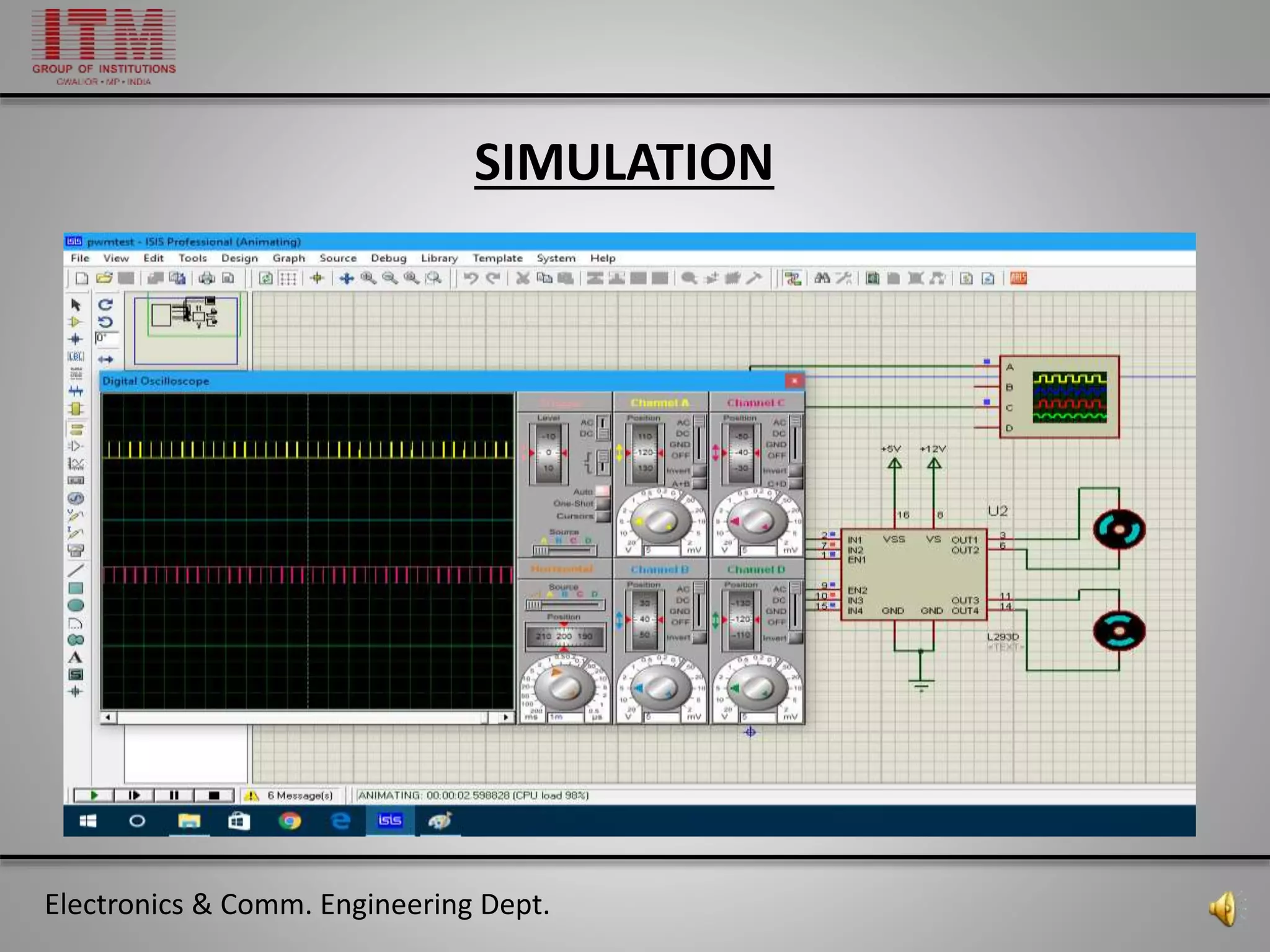

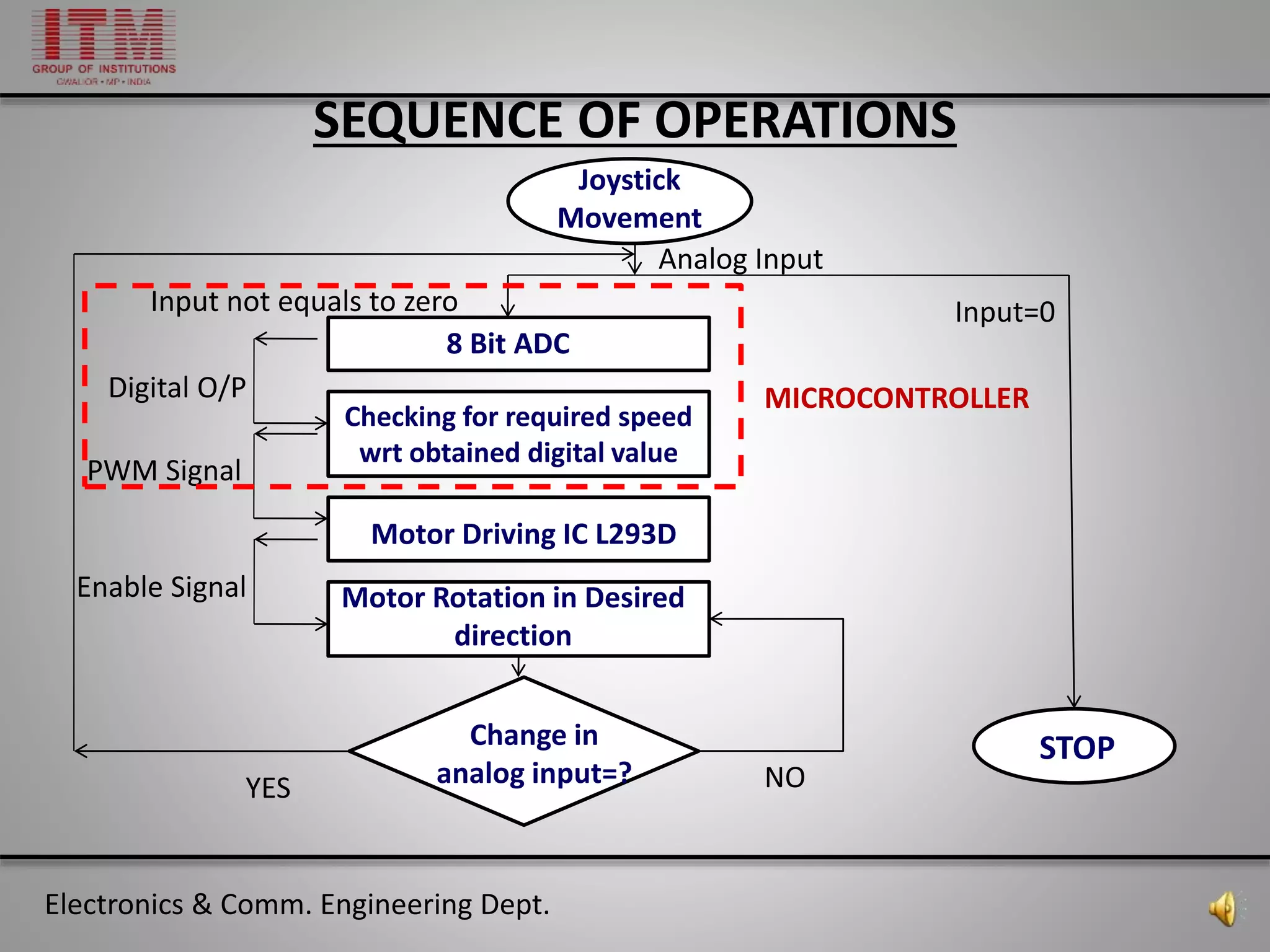

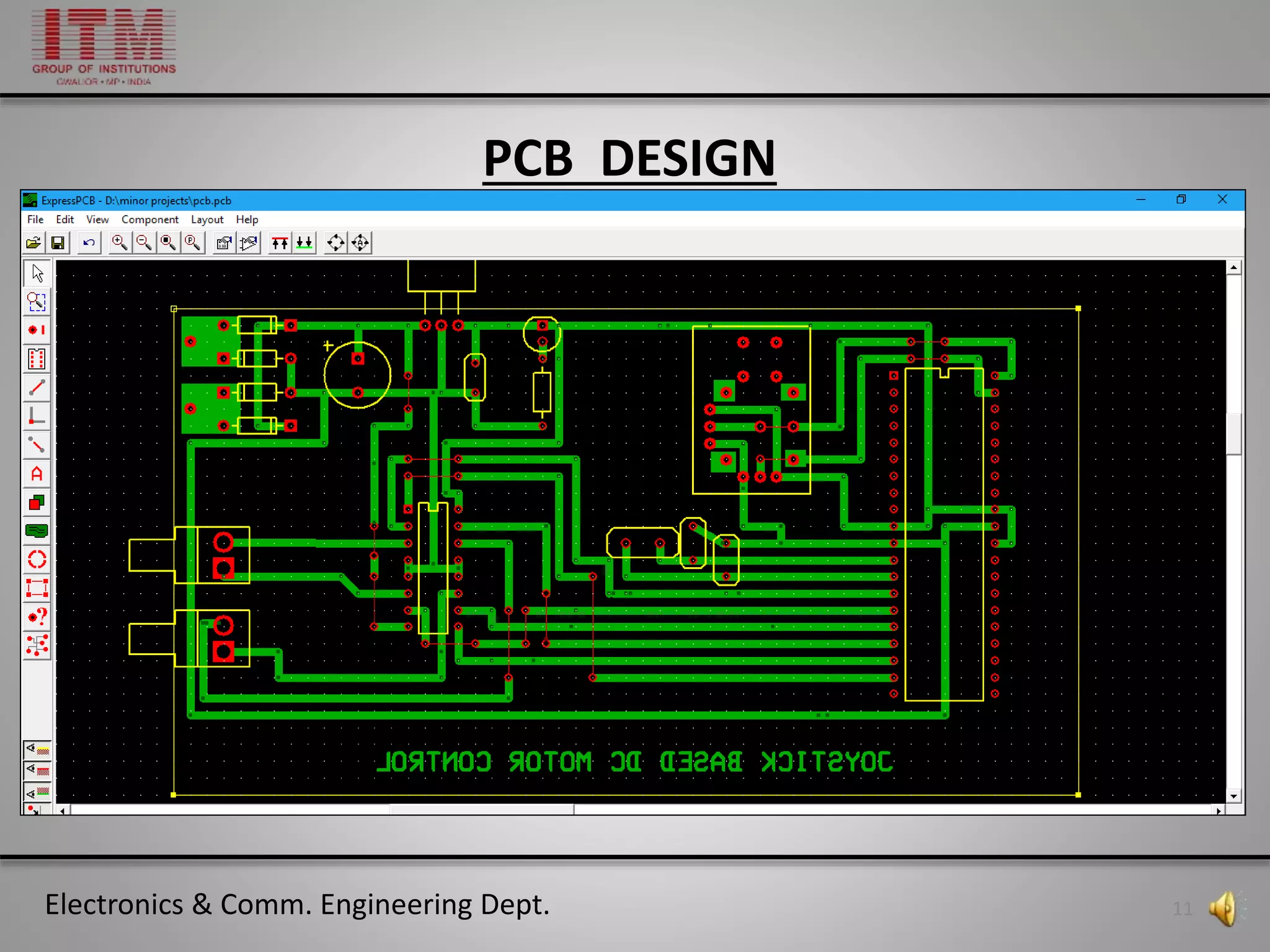

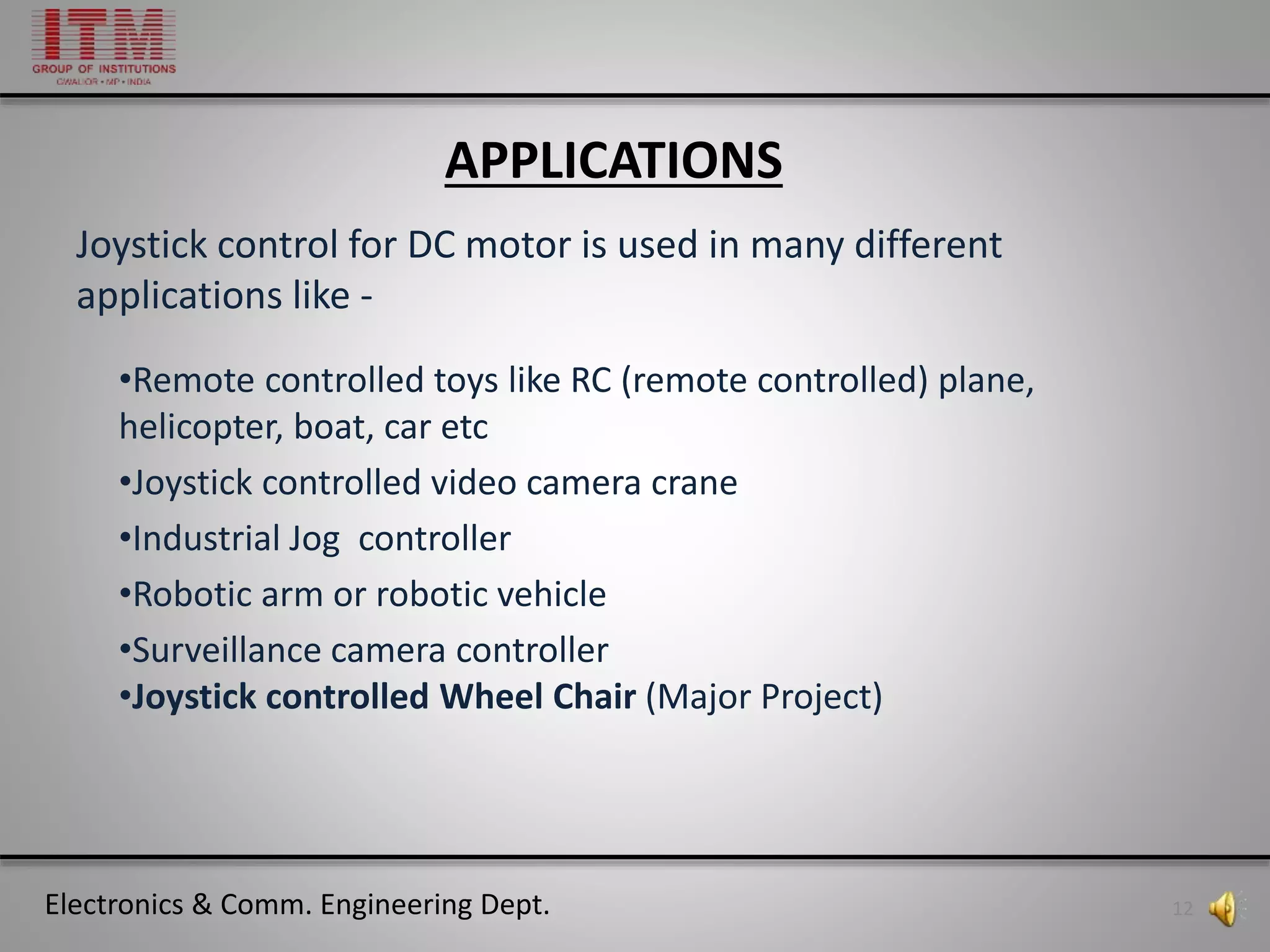

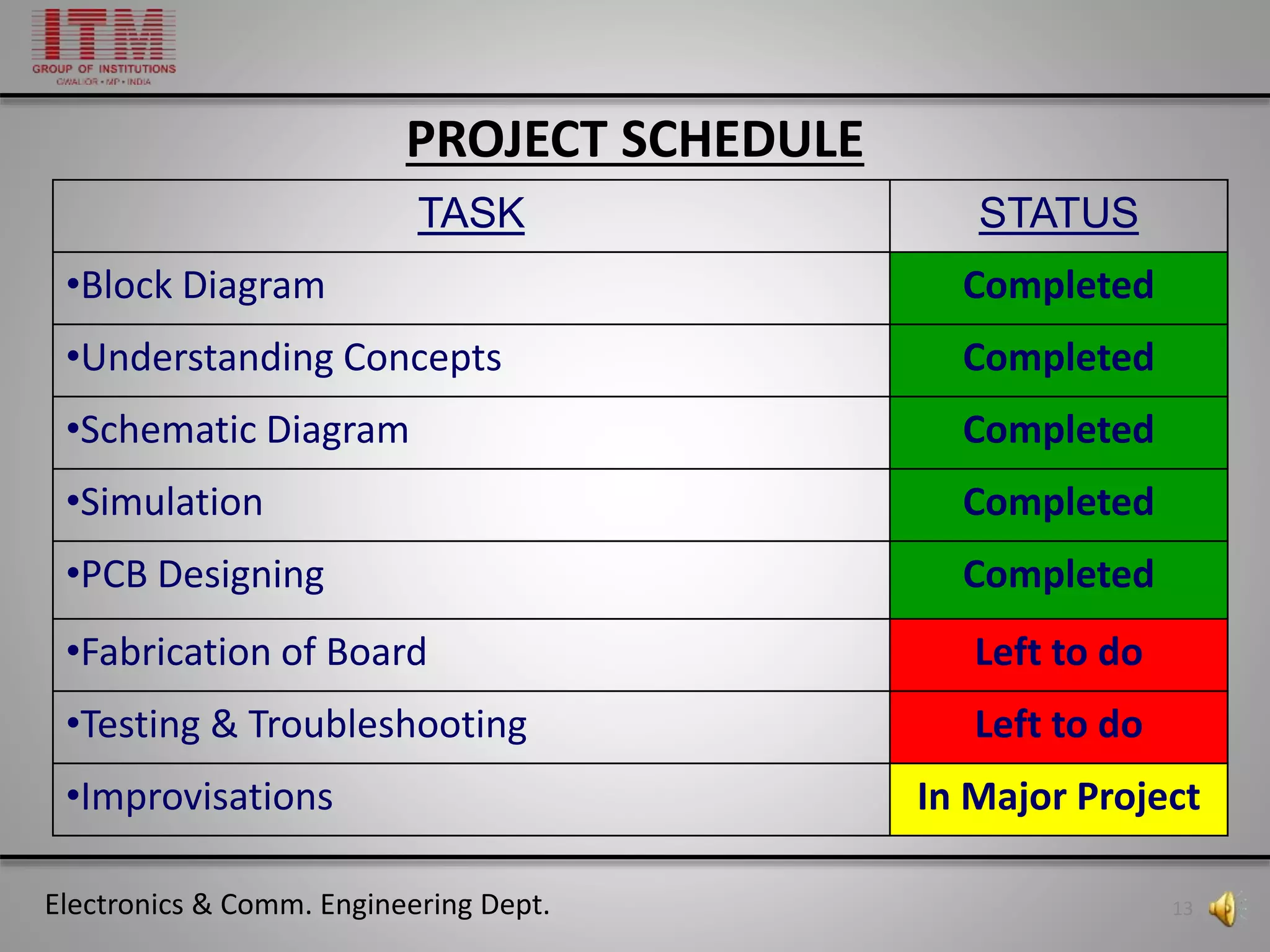

This document outlines a project guide for controlling DC motors using a joystick, highlighting the necessary components such as an ATmega16 microcontroller and PWM technique. The project includes detailed sections on requirements, block diagrams, operation concepts, and applications in fields like robotics and remote-controlled vehicles. Additionally, it provides the project schedule, budget, and references for further reading.

![JOYSTICK BASED DC MOTOR

CONTROL

PROJECT GUIDE - Mr. Rajkumar Rajoria

TEAM MEMBERS - Vaishnavi Agrawal [0905EC131178]

Shivani Bhargava [0905EC131152]

Electronics & Comm. Engineering Dept.](https://image.slidesharecdn.com/slideshare-161201041402/75/JOYSTICK-BASED-DC-MOTOR-SPEED-CONTROL-SYSTEM-by-VAISHNAVI-AGRAWAL-1-2048.jpg)