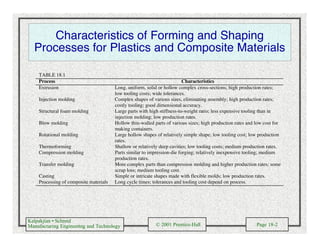

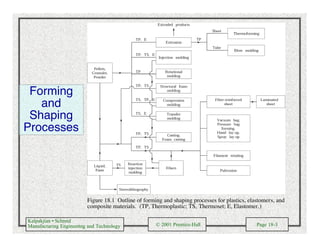

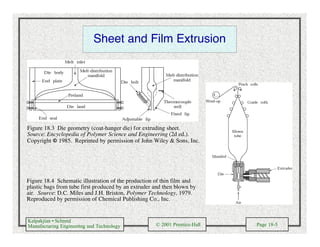

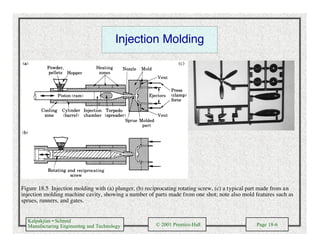

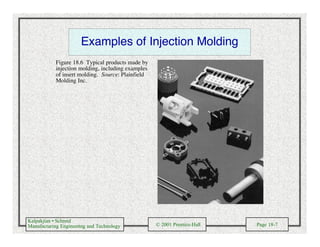

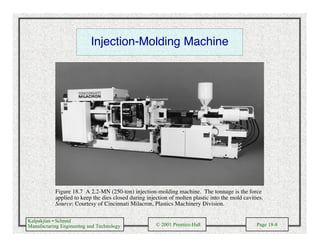

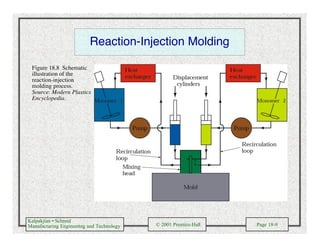

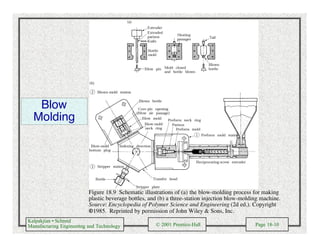

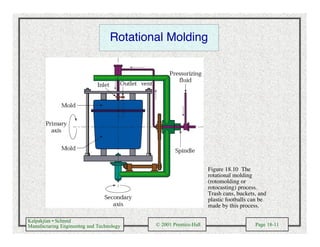

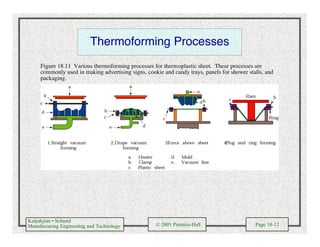

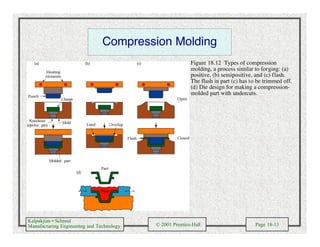

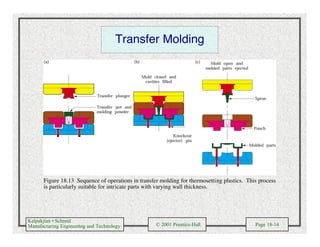

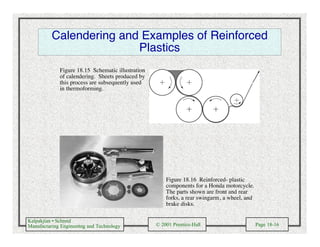

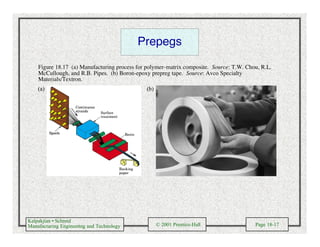

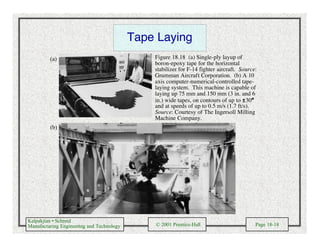

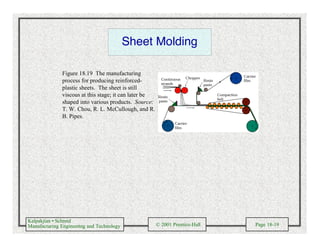

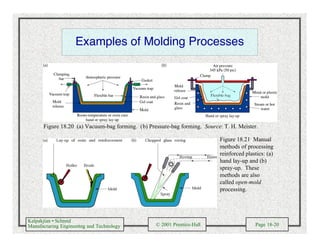

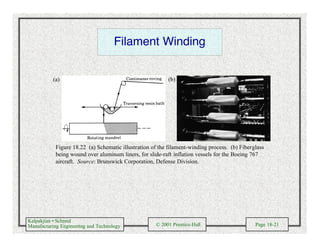

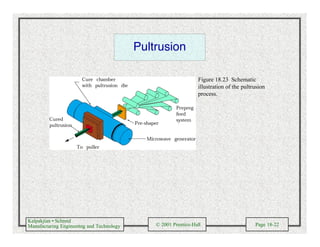

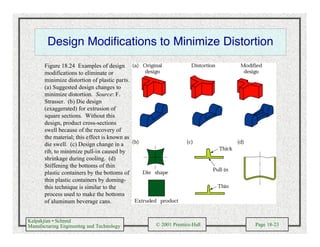

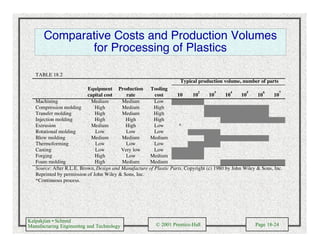

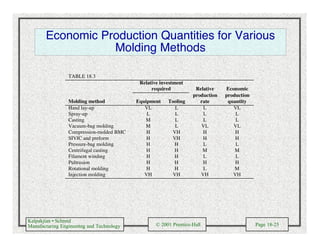

The document discusses various forming and shaping processes for plastics and composite materials. It describes common processes like extrusion, injection molding, blow molding, rotational molding, compression molding, and others. For each process, it provides information on characteristics, typical applications, production rates, tooling costs, and capabilities regarding part geometry and complexity. Diagrams and figures are also included to illustrate key aspects of several processes.