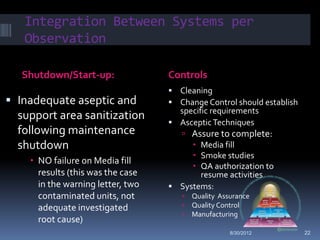

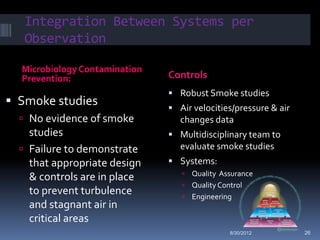

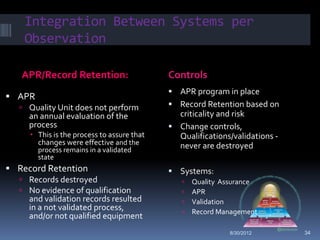

The document discusses the integration of Good Manufacturing Practice (GMP) systems as compliance tools in the pharmaceutical industry, highlighting various components such as cleaning validation, investigations, and supplier qualifications. It reviews recent observations from health authorities, emphasizing failures in batch investigations and the management of contamination risks. The content includes a call for better controls and communication among systems to ensure sustainability and compliance.