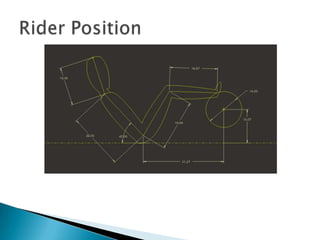

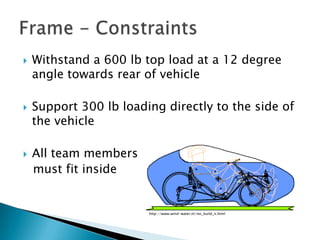

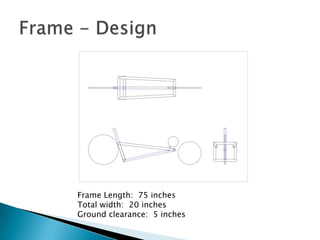

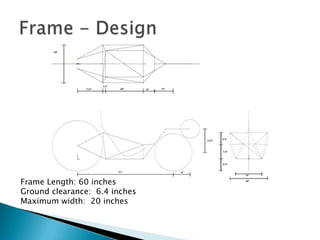

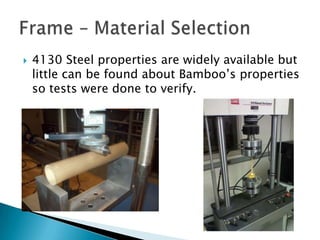

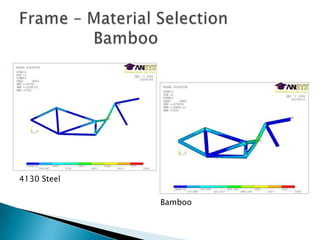

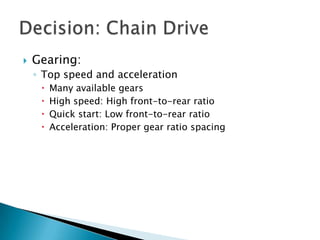

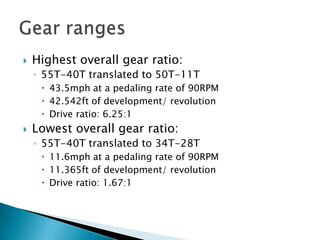

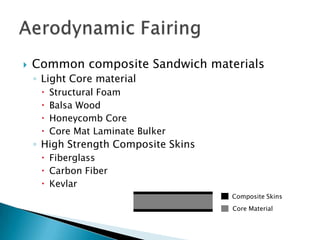

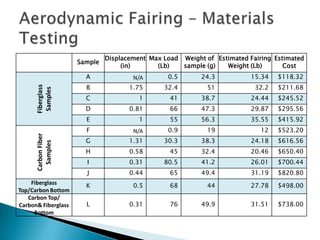

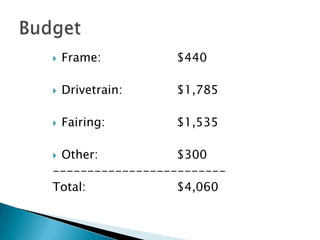

The document summarizes the design and construction of a single-rider human powered vehicle for a competition. It discusses the objectives to design and build a recumbent bike that can win races for speed and endurance. Key aspects summarized include the frame design using bamboo for its strength and lightweight properties, a chain drive system with a wide gear range, aerodynamic fairing construction using composite sandwich materials, and a total project budget of $4,060.