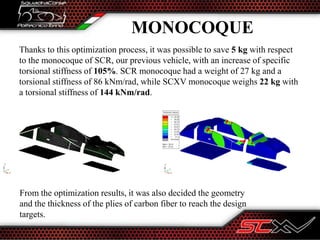

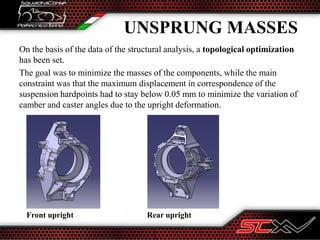

The document details the design and development of the SCXV, an electric formula SAE car by the squadra corse of the Polytechnic University of Turin. Utilizing Altair software for structural analysis and optimization, the team achieved significant improvements in weight and stiffness of the car's components, including the monocoque and uprights. The car features a 4WD system with four electric motors and emphasizes self-designed electronics, aiming to compete in global formula SAE events.