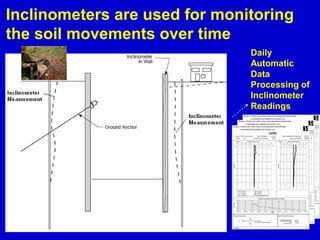

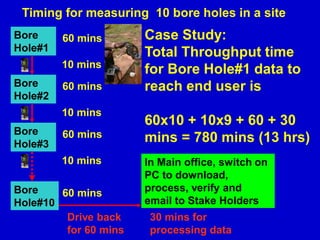

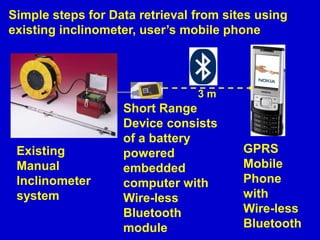

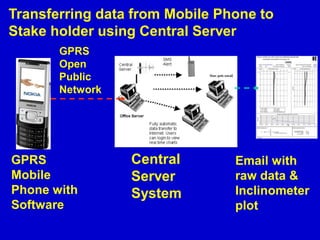

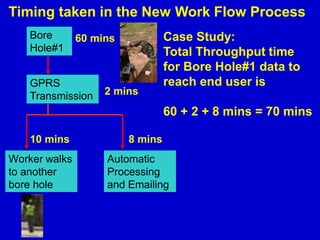

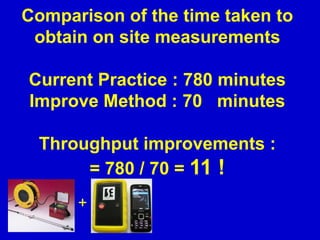

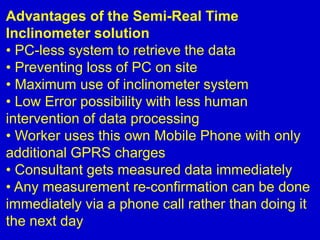

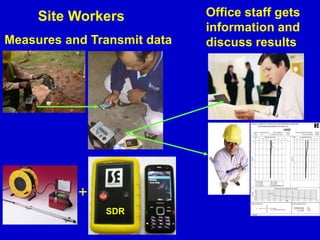

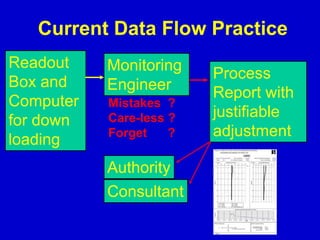

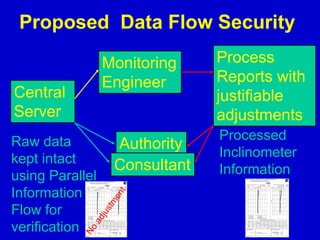

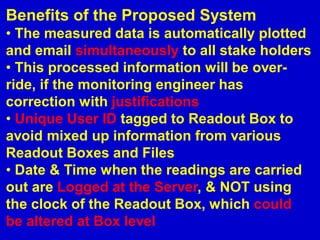

This document describes a new method for taking semi-real time inclinometer readings using wireless technologies. The current practice of downloading data from inclinometers to a PC on site and then transporting the PC back to the office takes over 13 hours for readings from 10 boreholes. The new method uses a battery-powered device with Bluetooth to transmit readings from the inclinometer to a worker's mobile phone. The data is then sent via GPRS to a central server where it is automatically processed, plotted, and emailed to stakeholders, taking only 70 minutes total. This provides an 11-fold improvement in throughput time and allows stakeholders to immediately discuss unexpected readings and monitor critical sites more safely and effectively. Feedback from users has been