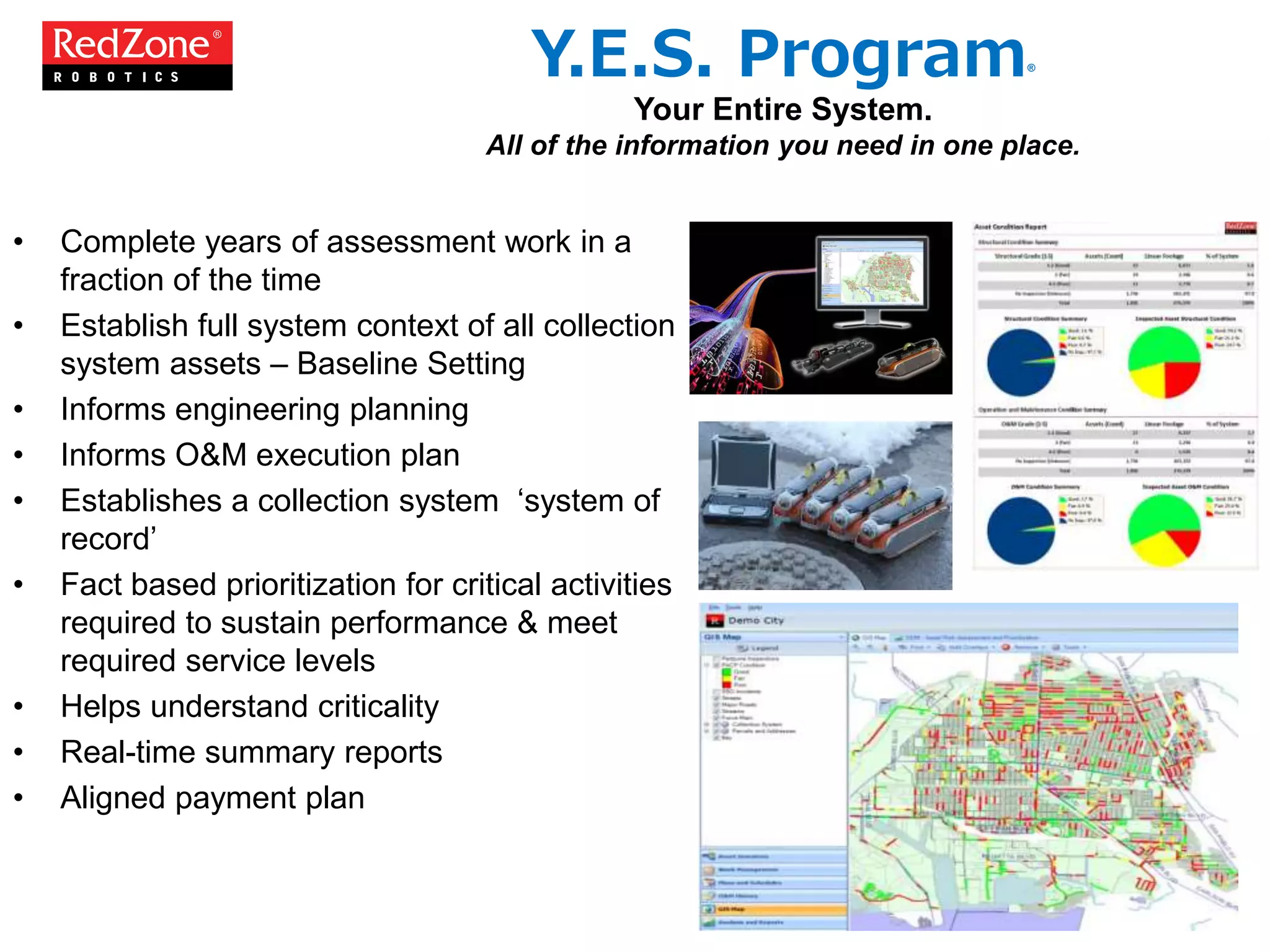

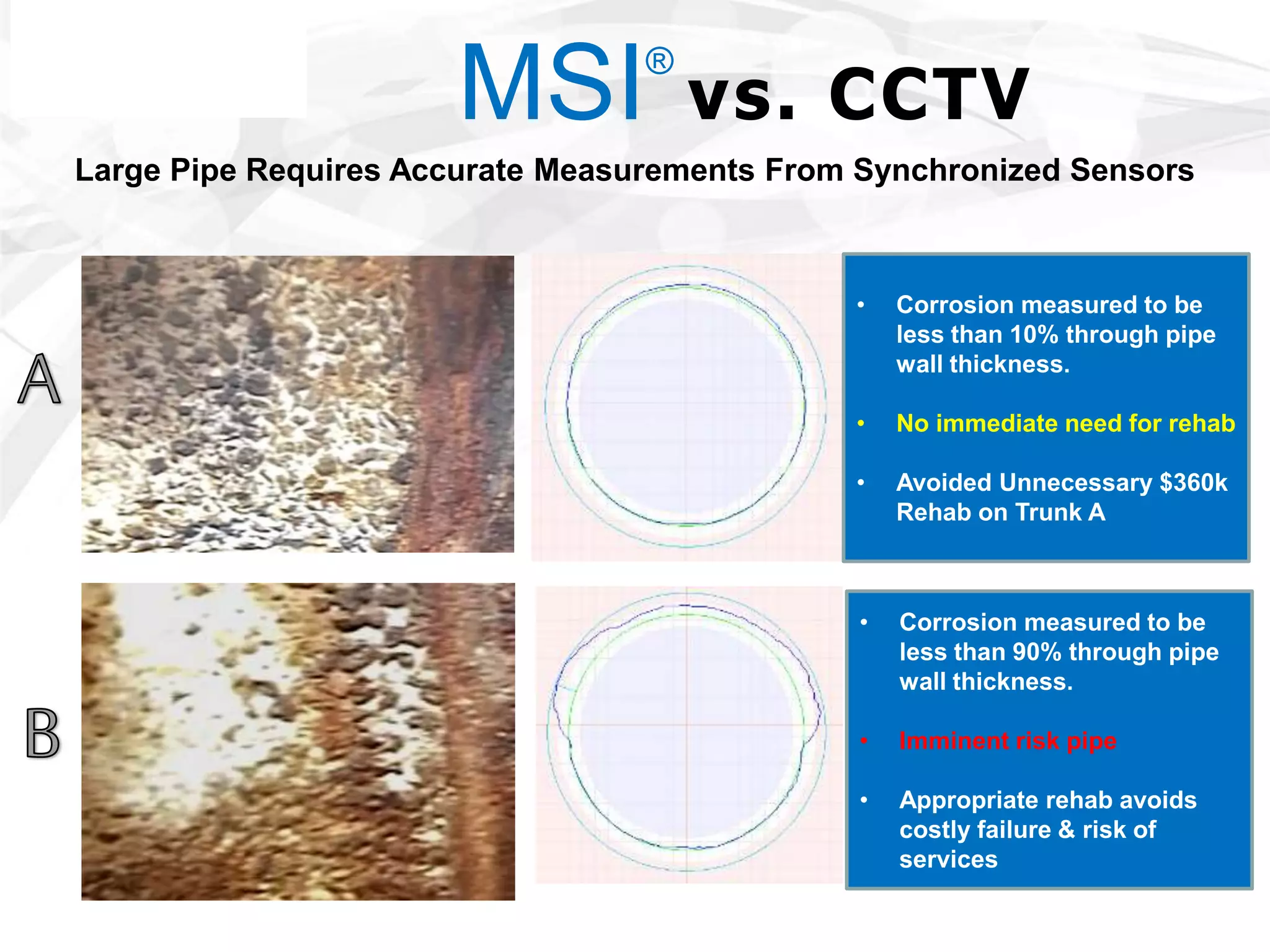

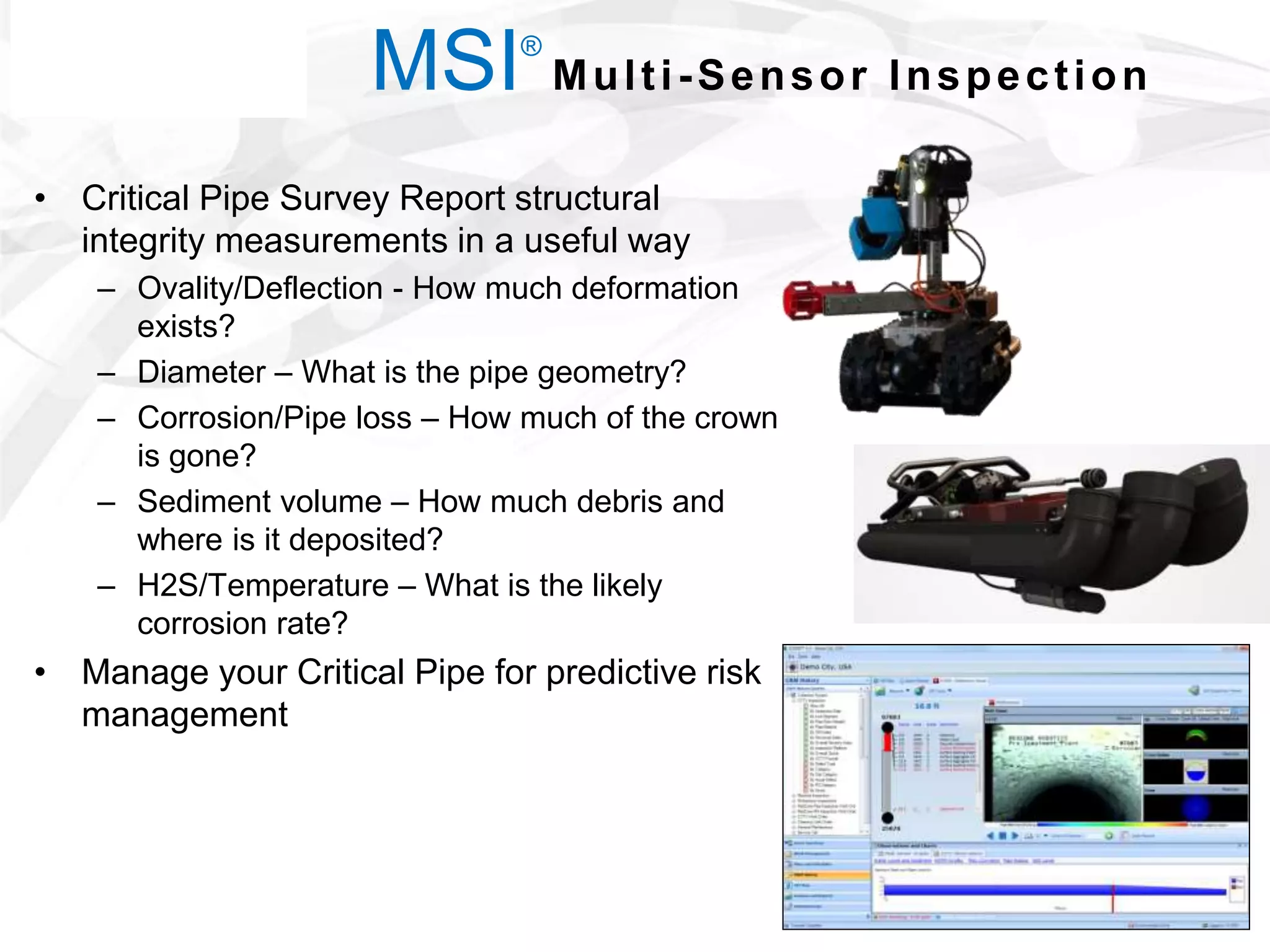

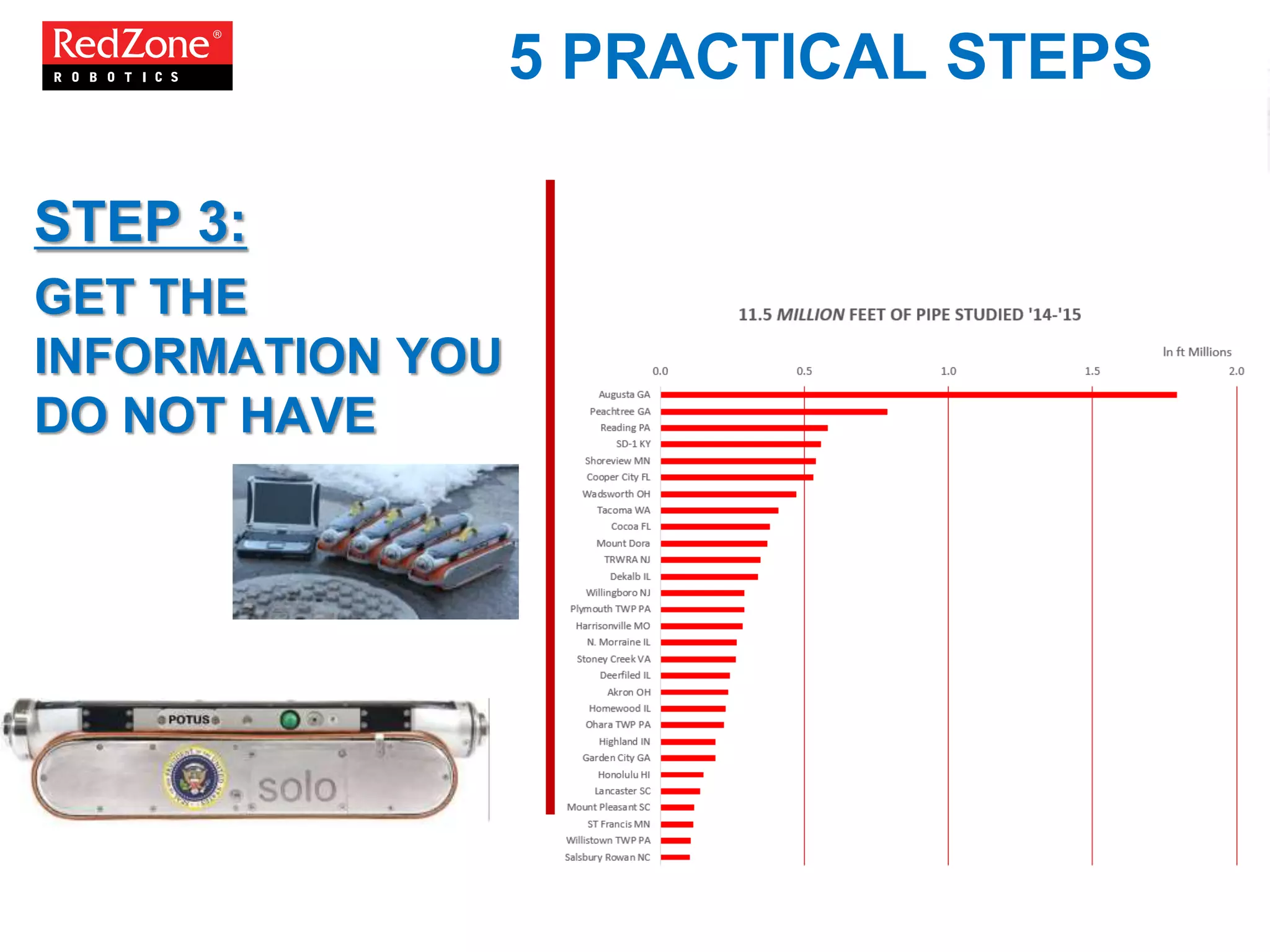

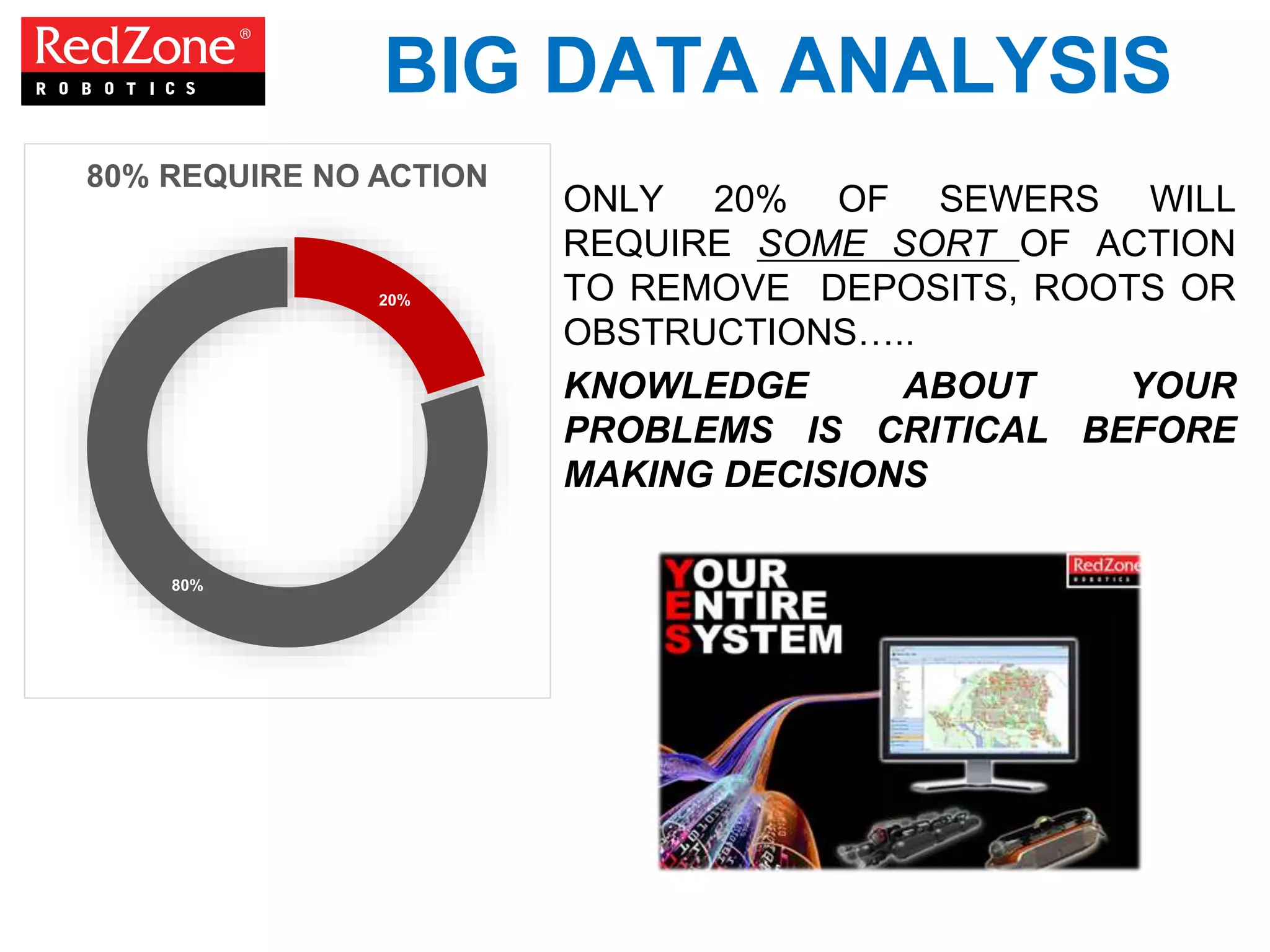

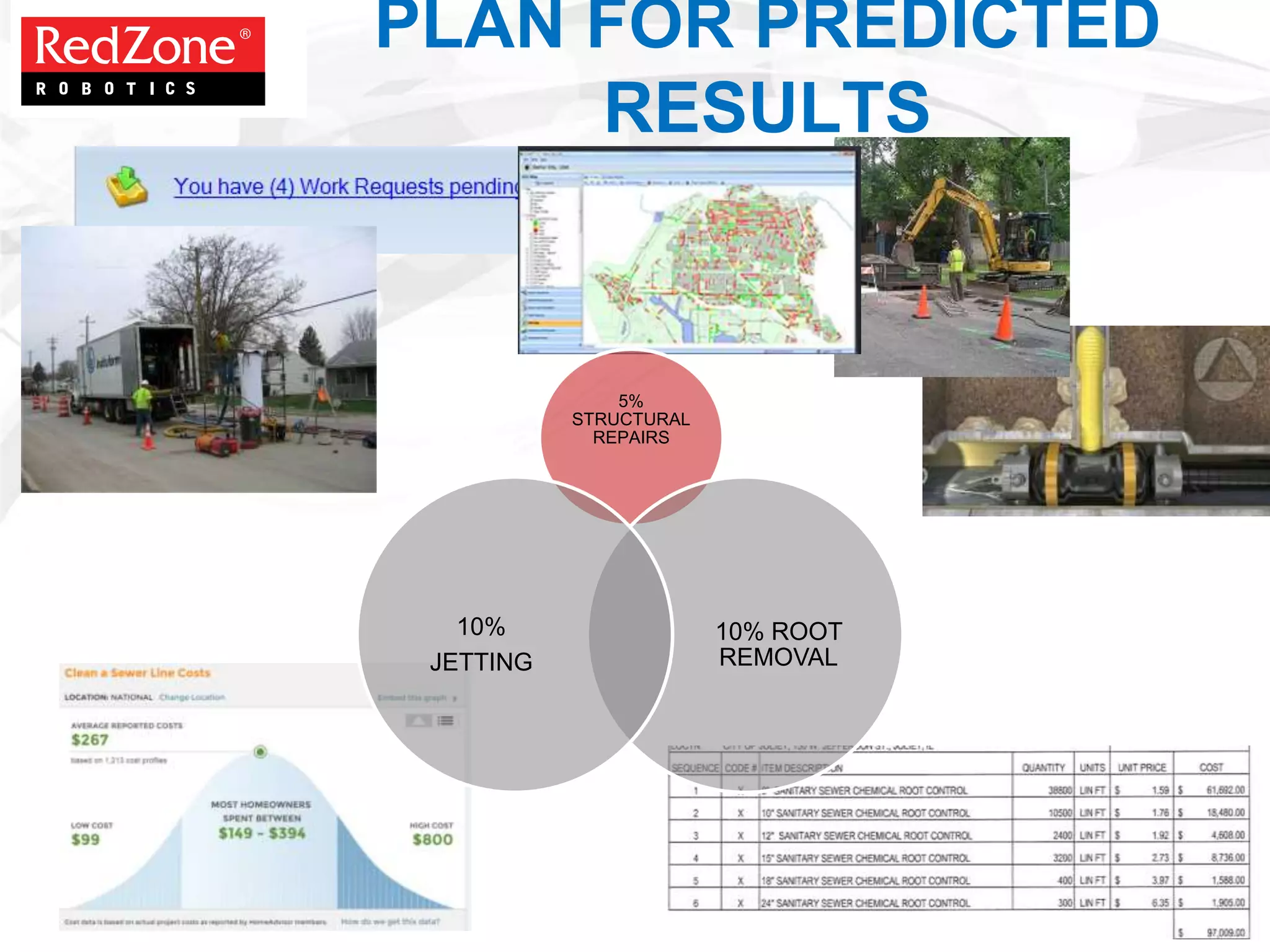

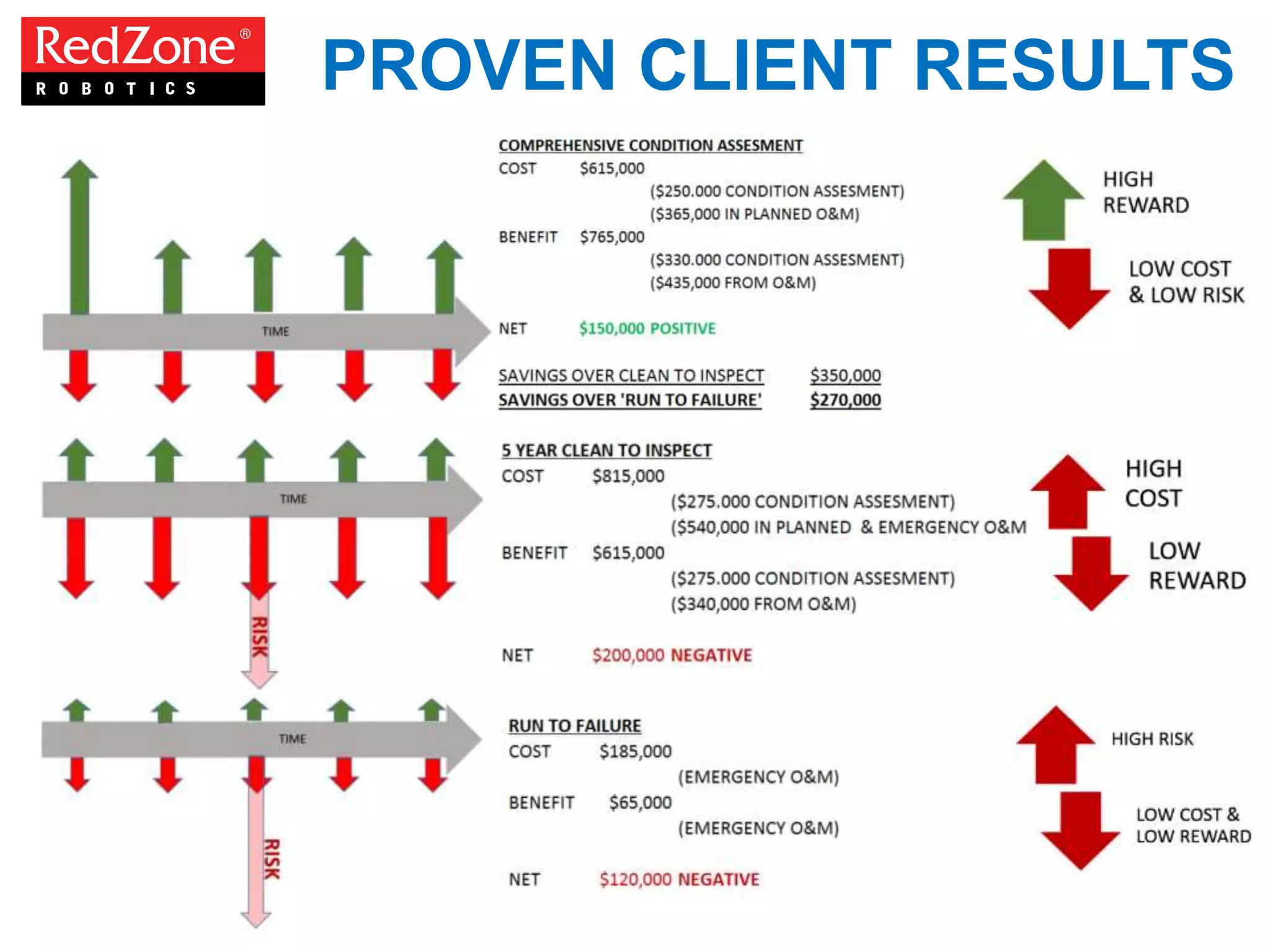

The document outlines a five-step process for implementing a collection system and results-oriented management using autonomous robots. Key steps include setting asset management goals, assessing data needs, and utilizing technology for efficient inspections. A specific focus is placed on the benefits of the innovative MSI® multi-sensor inspection system, which enhances data quality while reducing risks and costs associated with traditional methods.