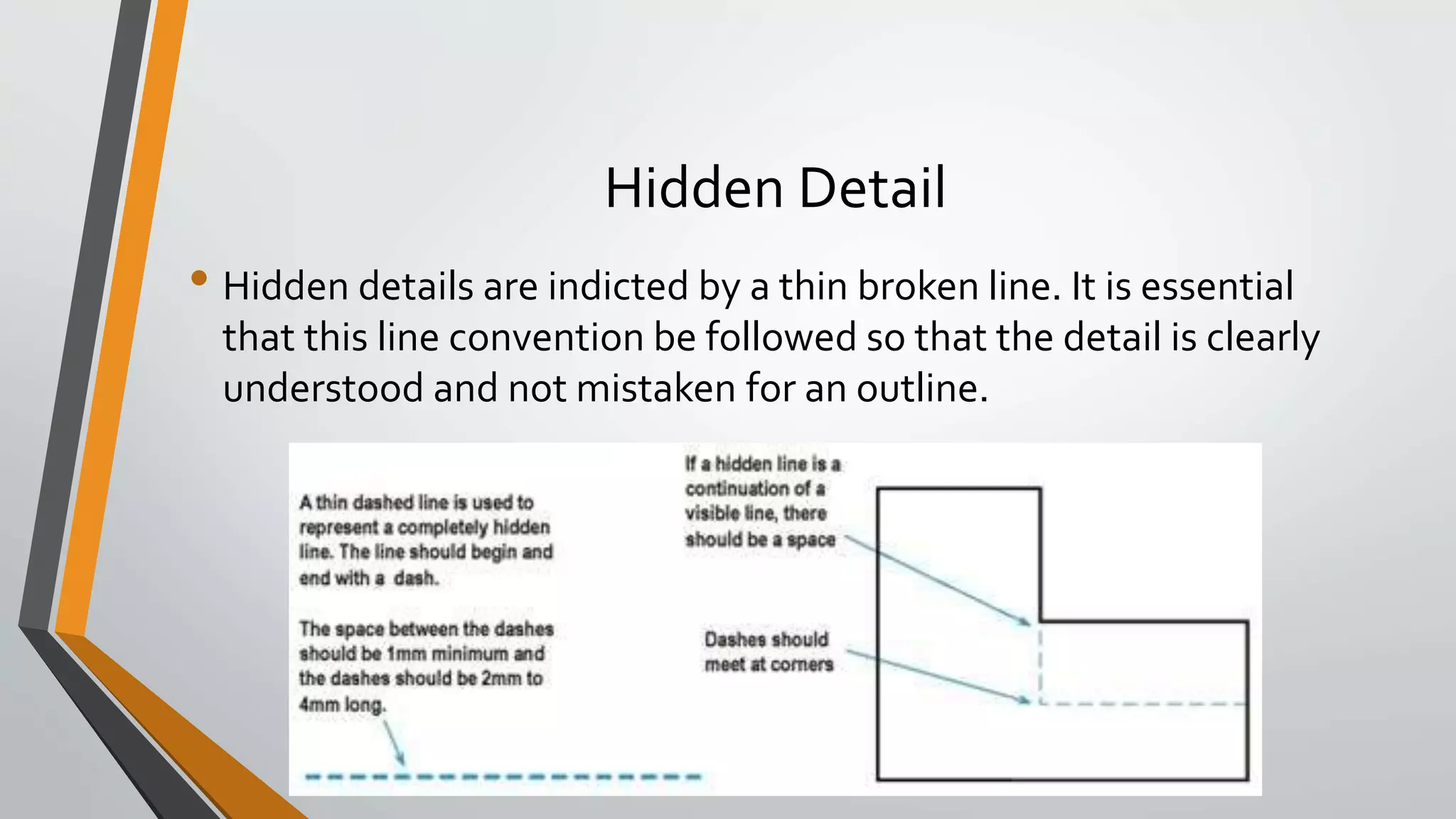

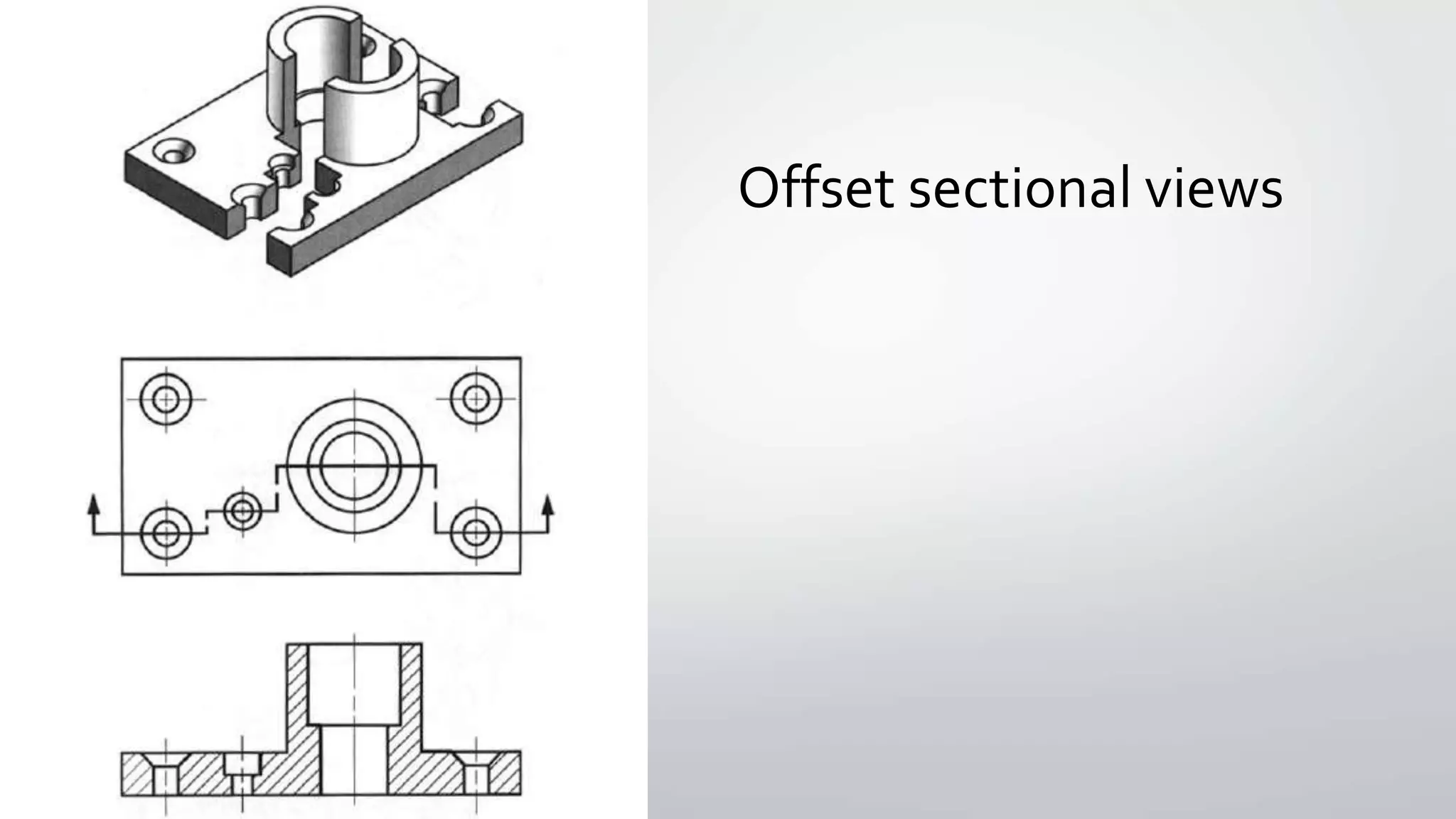

This document discusses different types of sectional views used in technical drawings to show internal geometry and hidden details, including full sectional views, half sectional views, and offset sectional views. It describes how sectional views are indicated using a cutting plane line and arrows, and how cross-hatching is used to represent cut areas. Rules for sectional views are provided, such as only cross-hatching the cut material and not placing full lines over cross-hatched areas.