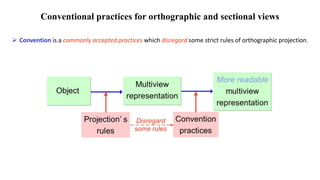

Conventional practices for orthographic and sectional views aim to improve drawing clarity, facilitate dimensioning, reduce drafting effort, and efficiently use drawing space. Some key conventions include using incomplete views, aligning symmetrical features between views, omitting section lines for certain features, and using broken sections, offset sections, and aligned sections to better represent complex geometries.