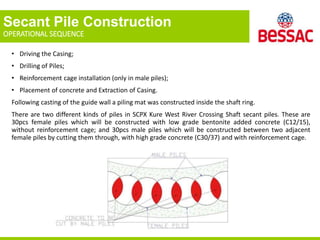

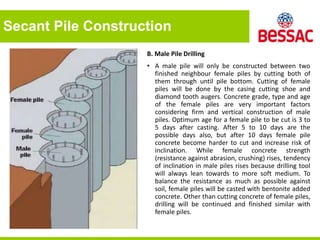

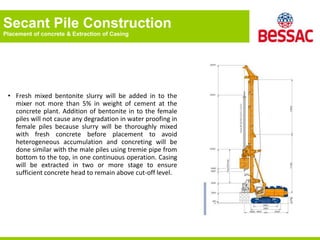

This document summarizes the process for constructing secant piles for a microtunnel shaft. It involves first constructing guide walls as reference points. Then female piles are drilled and concreted without reinforcement cages using lower grade concrete. Male piles are drilled between female piles, cutting through them. Reinforcement cages are installed in male piles before higher grade concrete is placed continuously from the bottom up via a tremie. The casing is gradually extracted to allow the concrete to rise above the cutoff level.