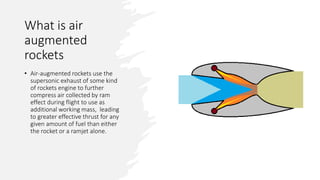

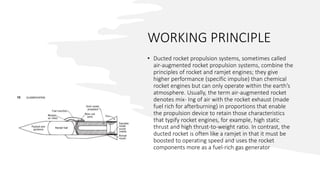

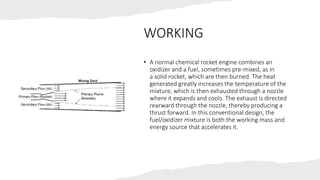

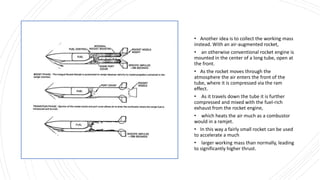

An air-augmented rocket uses a rocket engine to compress incoming air during flight, increasing total thrust. It was first developed by the Soviets in 1958 but did not enter mass production until 2016 in the Meteor air-to-air missile. It works by using a rocket exhaust to compress and heat incoming air in a duct, similar to a ramjet but able to operate from zero speed. This extra air acts as additional propellant, improving fuel efficiency over a traditional rocket. However, air augmentation is limited by atmospheric thinning at high altitudes and difficult intake design requirements.