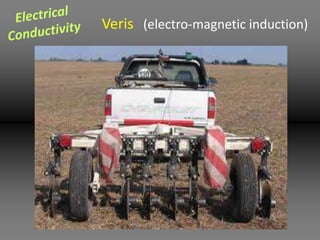

This document provides an overview of the history and future of precision agriculture. It discusses early efforts using soil testing and yield monitors in the 1990s. Current technologies like crop canopy sensors that measure biomass and chlorophyll are highlighted. The document also reviews ongoing work optimizing in-season nitrogen management. International collaboration between USDA-ARS and Embrapa Brazil on precision agriculture research is summarized.