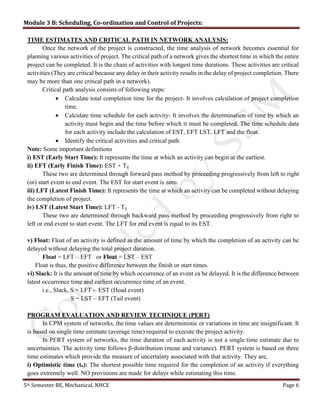

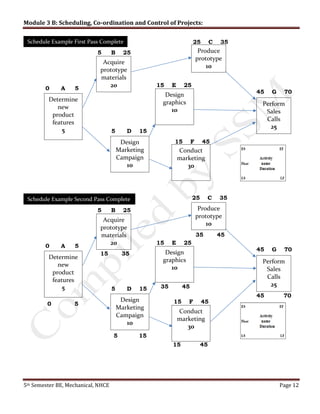

This document discusses project scheduling techniques. It provides definitions of key scheduling concepts like activities, logical relationships, and network diagrams. The document traces the historical development of scheduling from basic Gantt charts to modern critical path method (CPM) and program evaluation review technique (PERT). It explains that CPM and PERT were developed in the 1950s and use activity networks to determine the critical path and project duration. The document also defines common network diagramming techniques like precedence diagramming method (PDM) and different activity relationships.