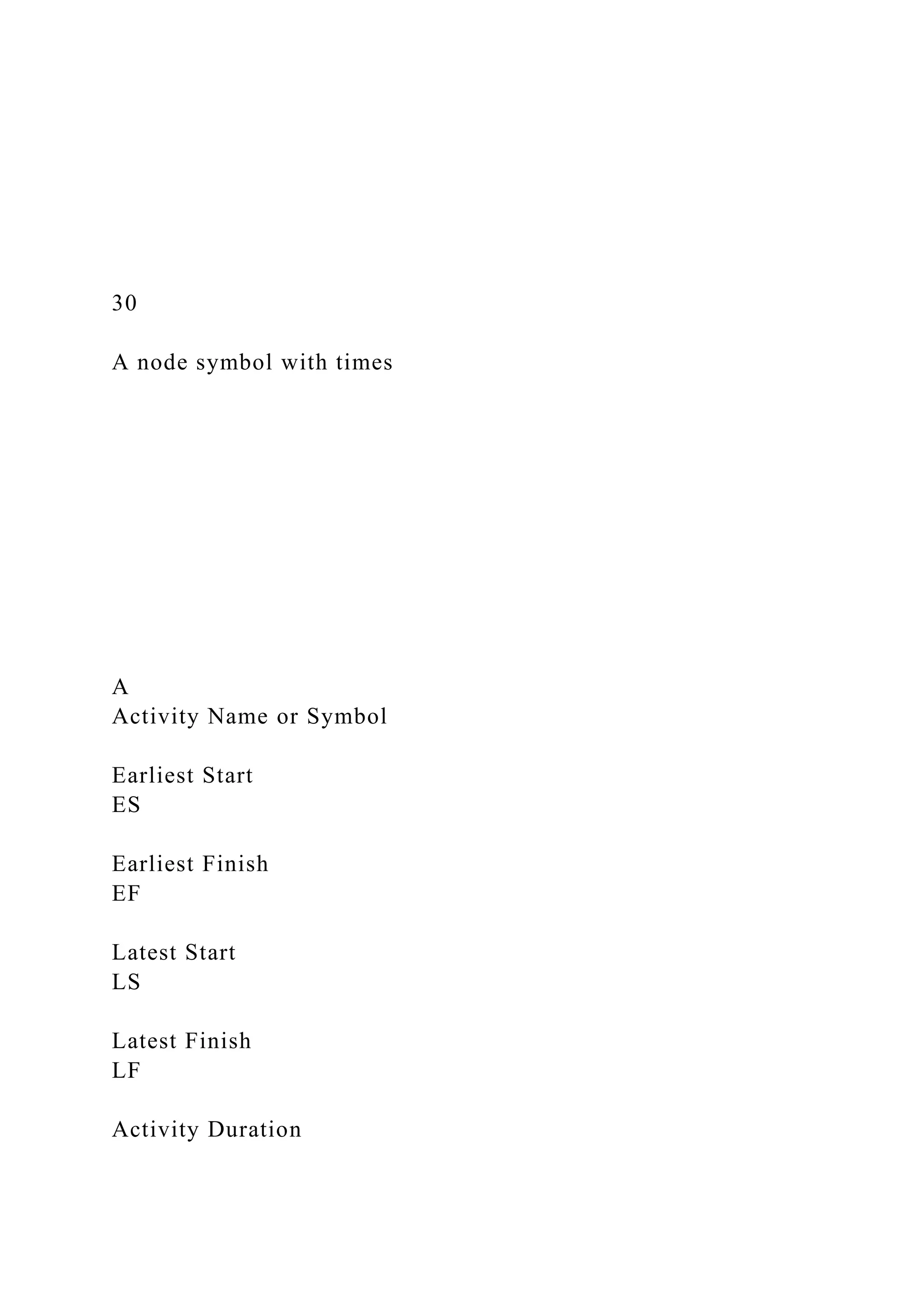

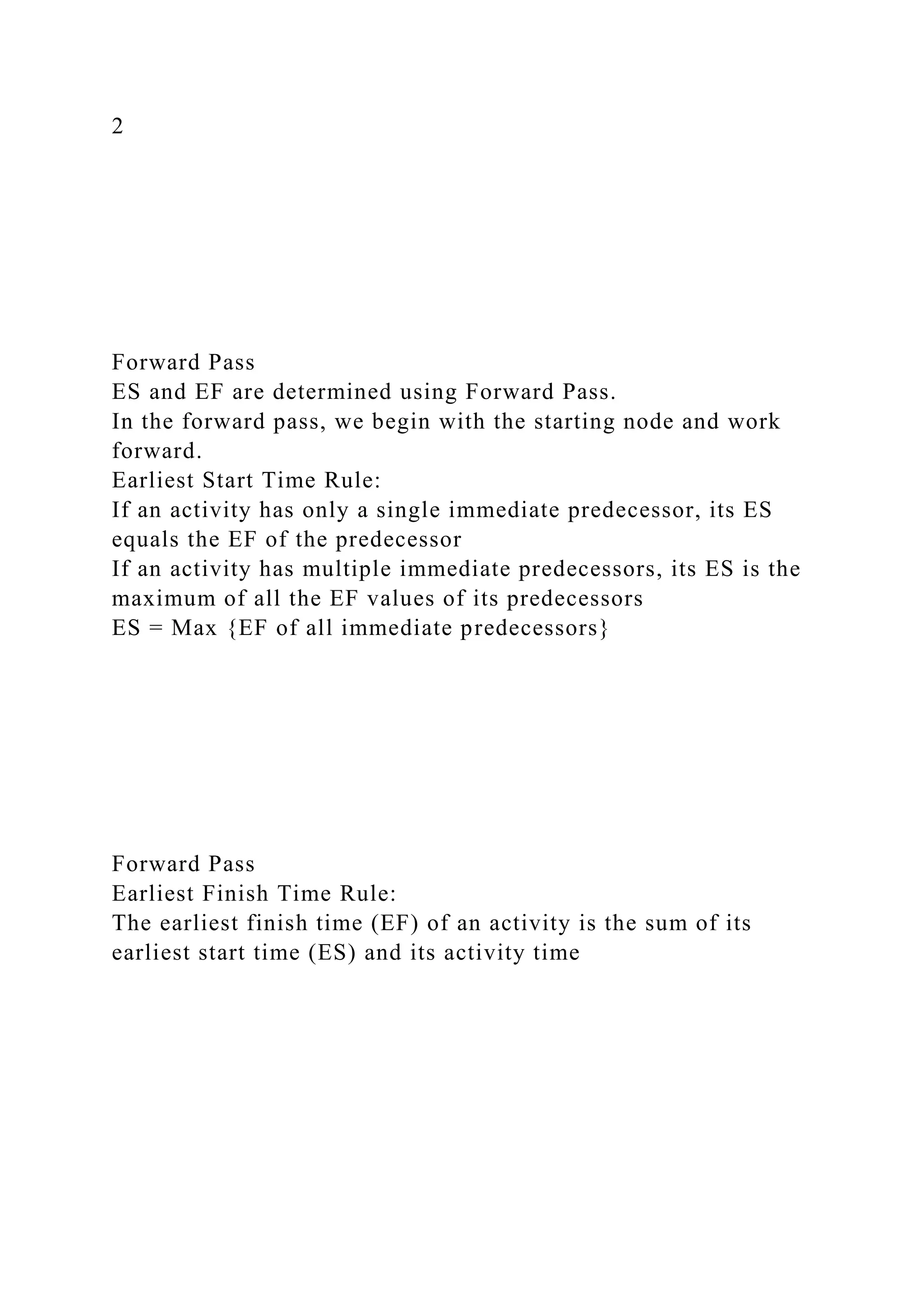

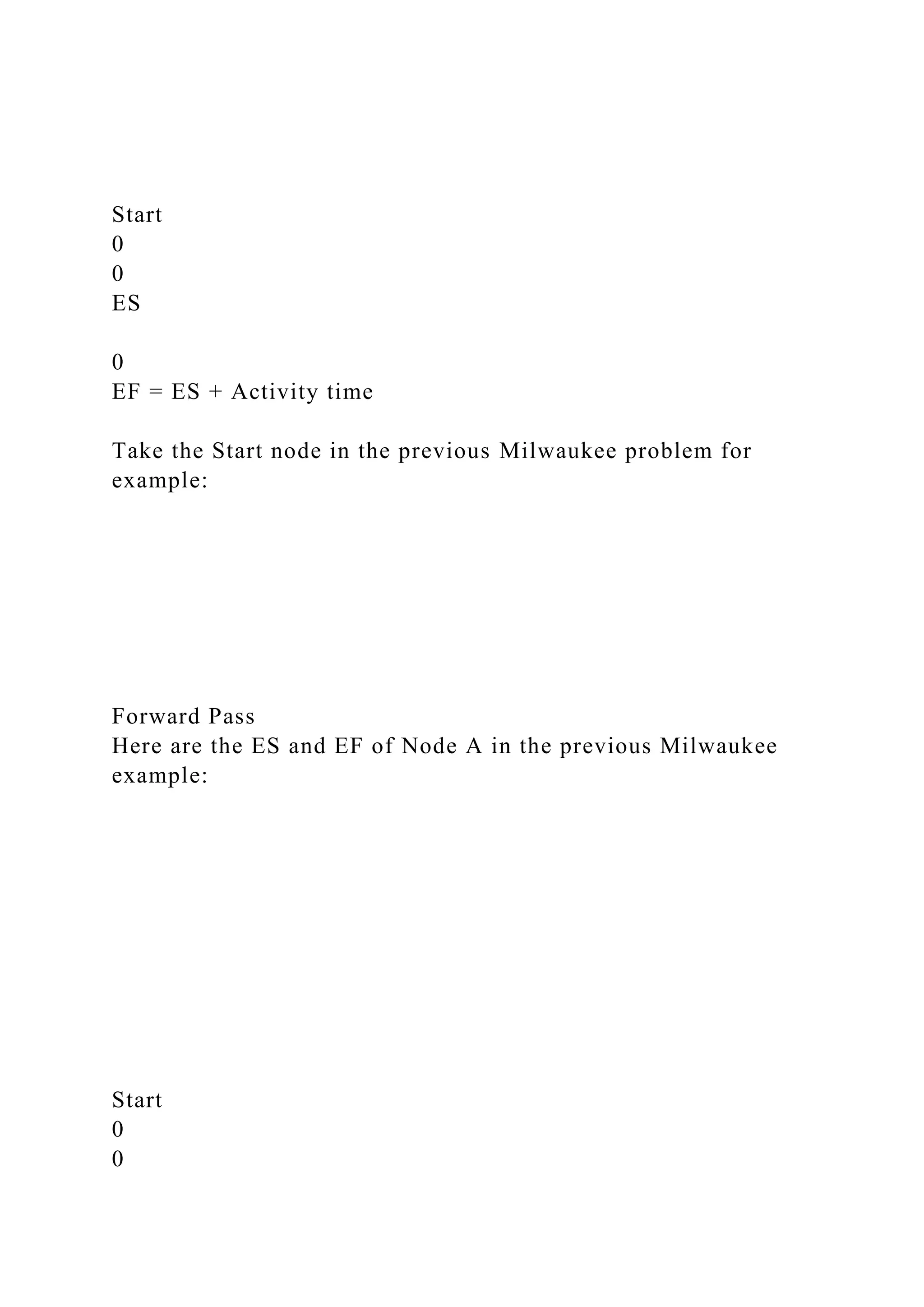

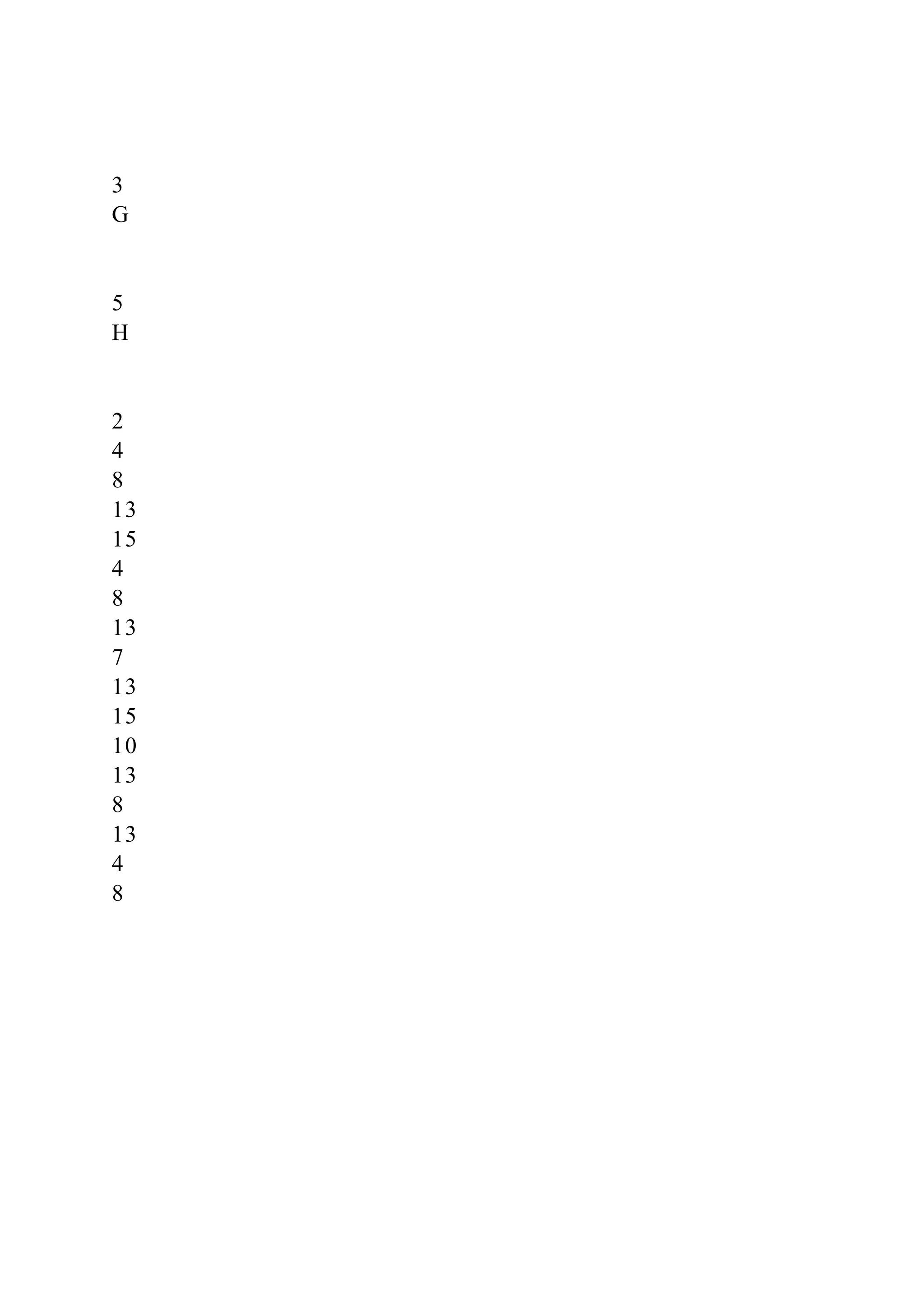

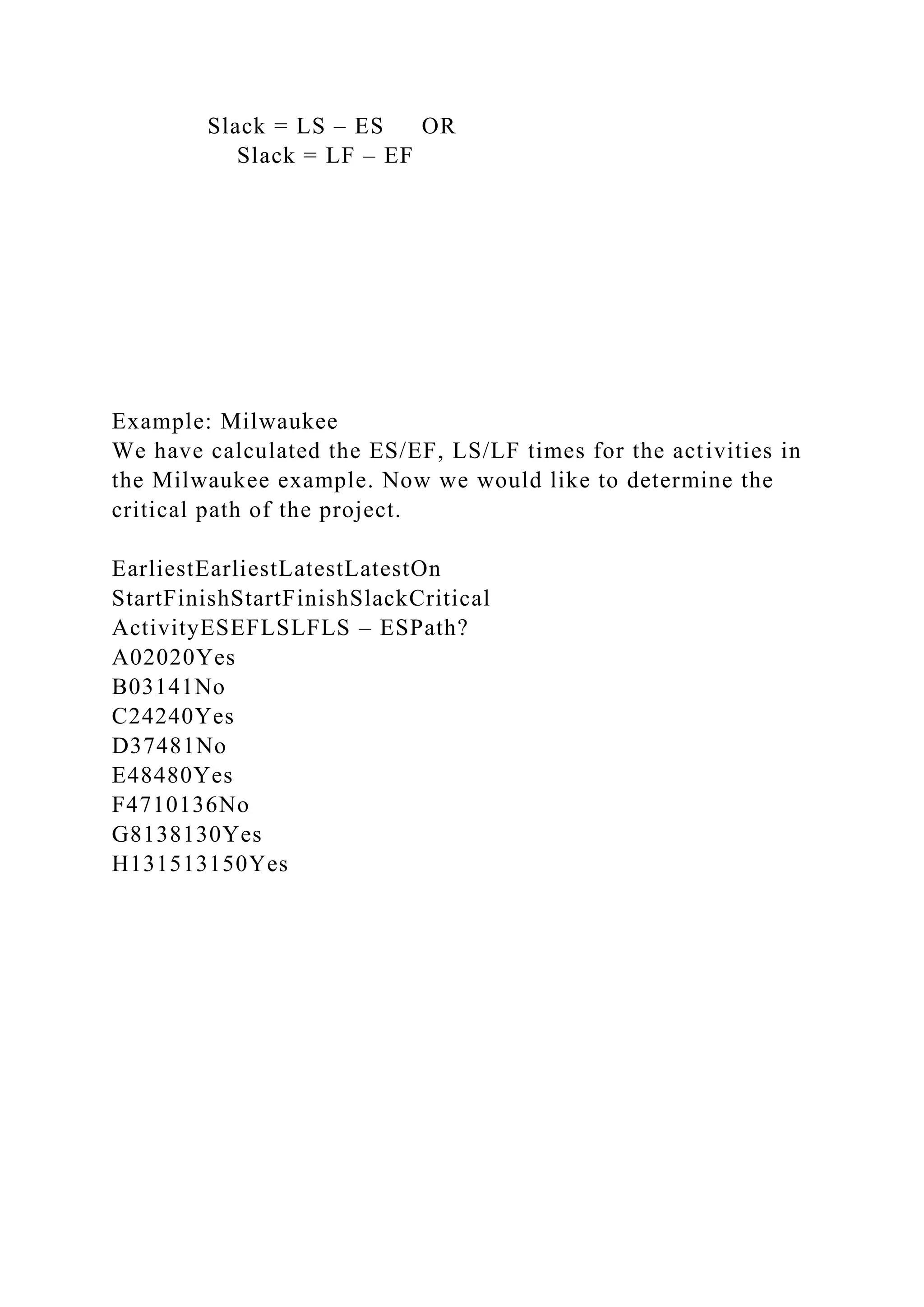

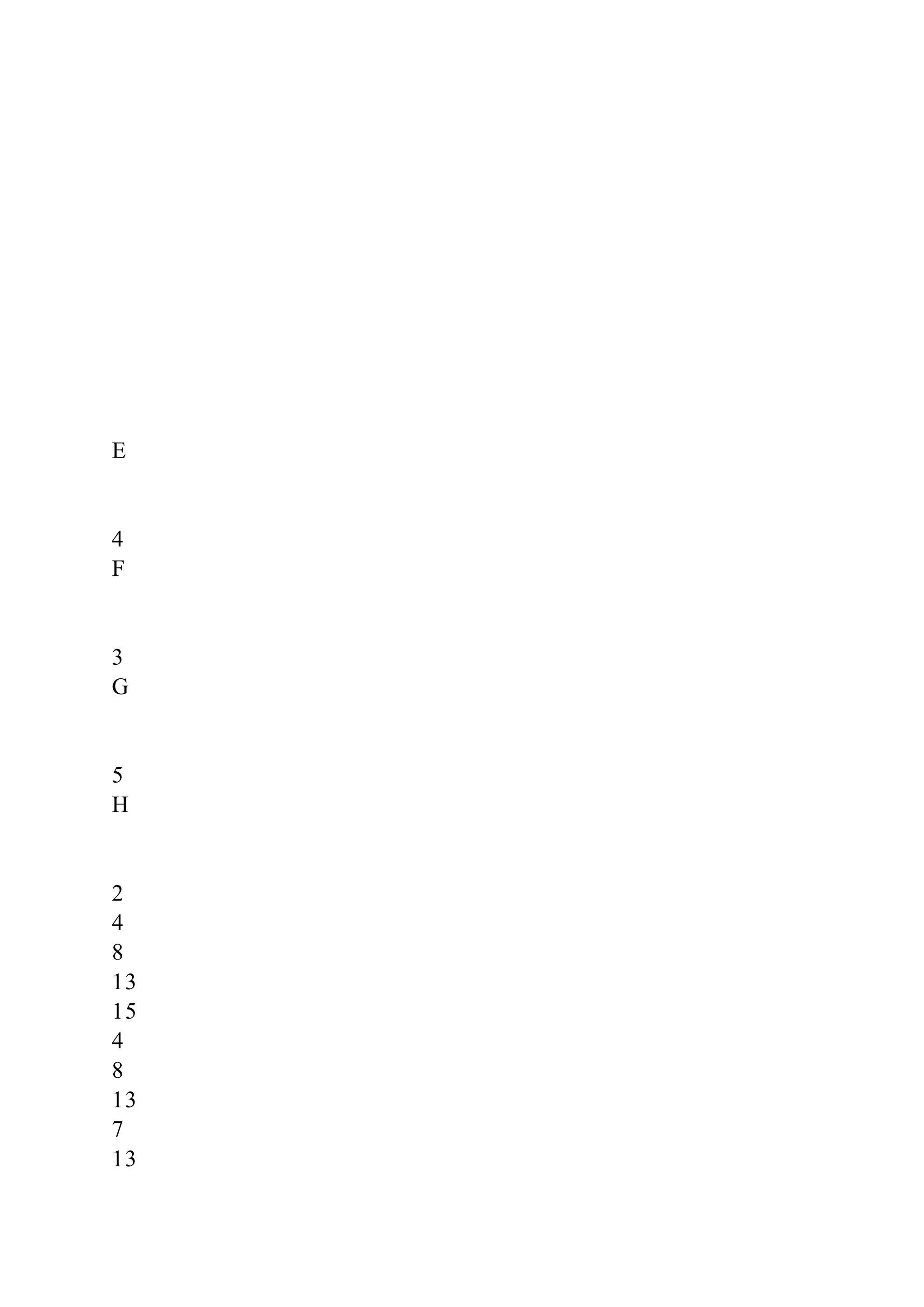

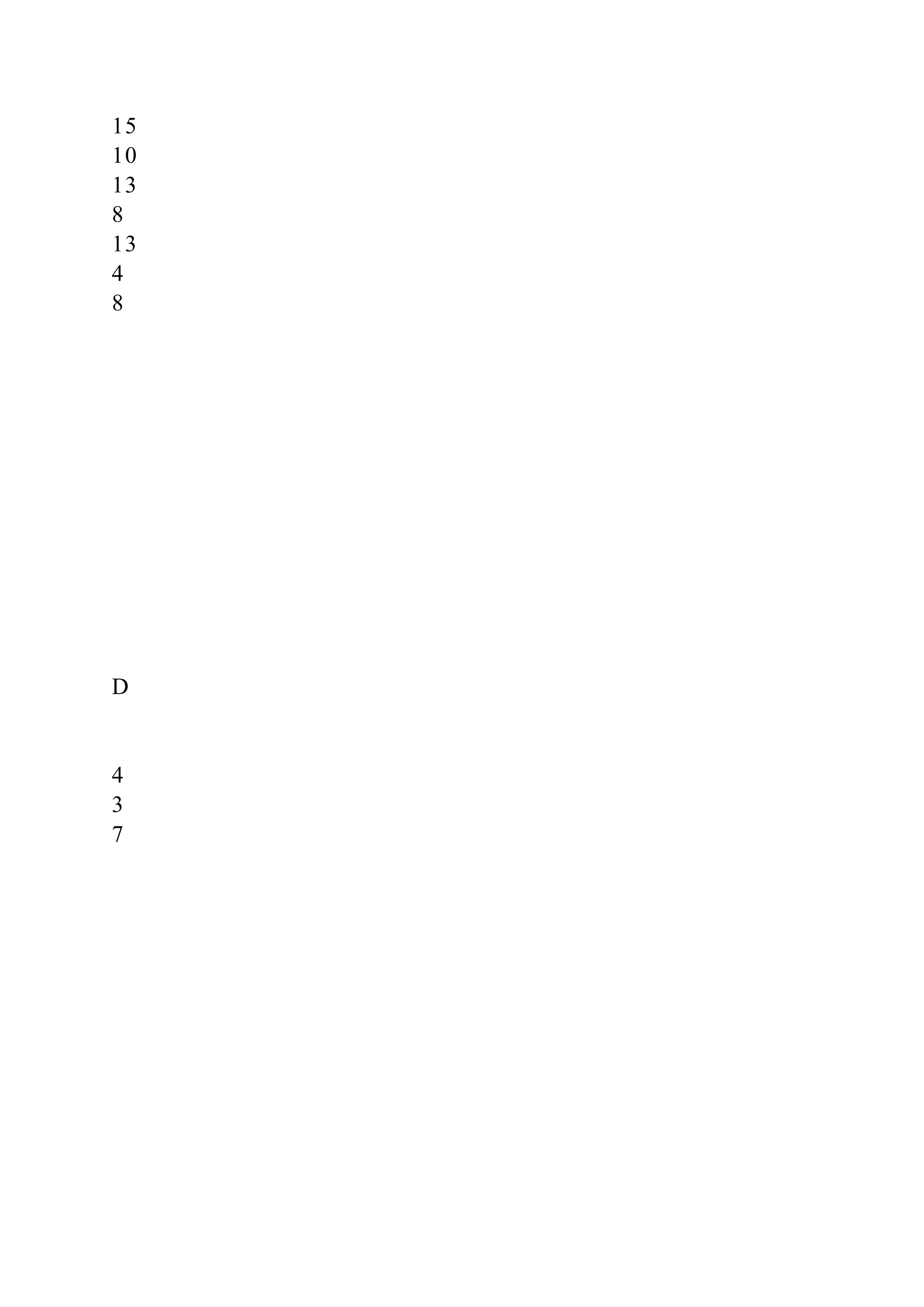

The document covers project management, defining it as the planning, scheduling, and controlling of resources for a major output. It discusses the work breakdown structure (WBS), three types of projects (pure, functional, matrix), and techniques like PERT and CPM for managing project timelines and costs. Additionally, it addresses project planning phases, the critical path method, and concepts such as slack time and project crashing for optimizing project delivery.

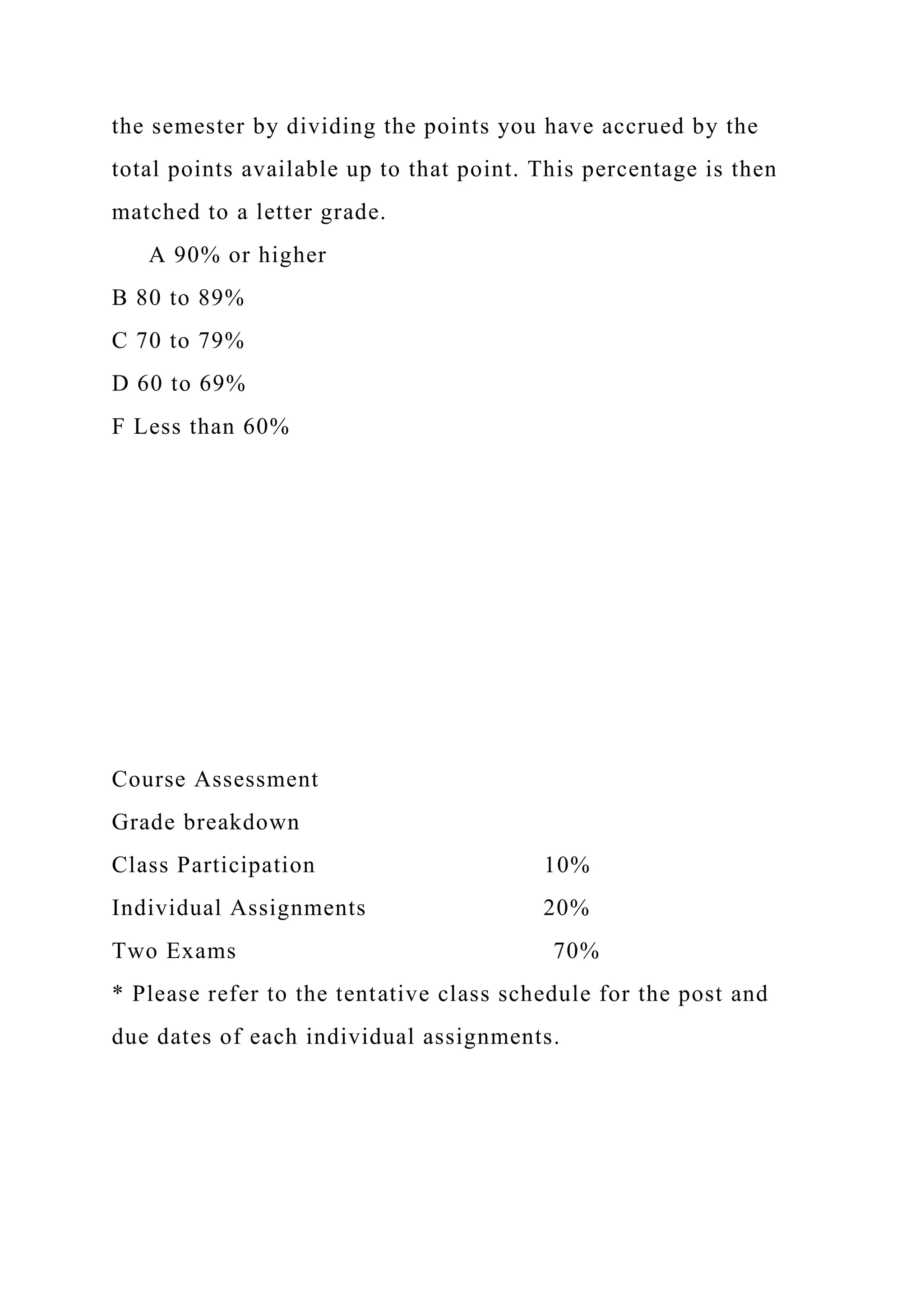

![the final grade.

Two Exams

There will be two non-cumulative exams in total. Each accounts

for 35% of the final grade. The exams will be individual, timed,

and open-book/notes. Only multiple-choice questions will be

given on the exams.

Contact information

Course Website: https://www.uhv.edu/elearning/login.aspx

Email: [email protected] or via “Messages” function in Learn 9

My Office: Room 338, Brazos Hall, UHSSL

Office Hours: 4:00 pm – 5:00 pm on Tuesdays or by

appointment (You can either drop by my office in Brazos Hall

or meet me online at: https://meetonline.uhv.edu/su15oscm/)

Office Phone number: 832-842-2958

For technical questions about Learn 9, please email our online

support technicians at [email protected] .](https://image.slidesharecdn.com/operationsandsupplychainmanagementmgmt3306lecture02i-221112193111-565653d9/75/Operations-and-Supply-Chain-ManagementMGMT-3306Lecture-02I-docx-74-2048.jpg)