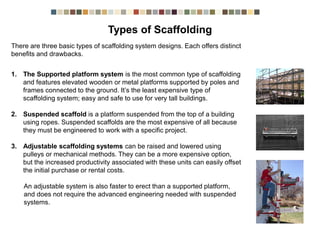

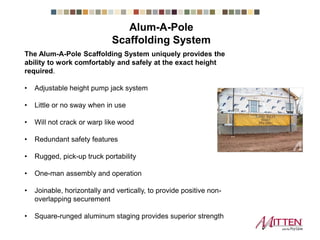

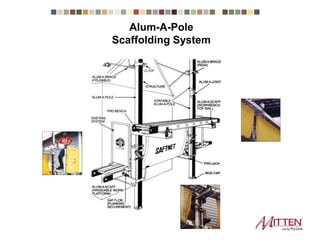

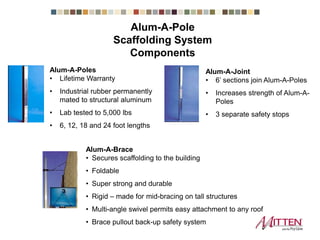

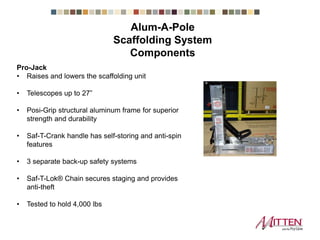

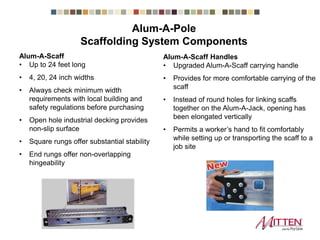

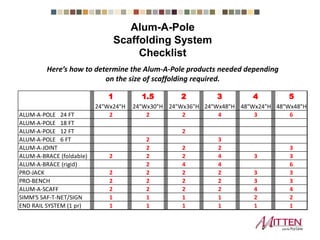

The document presents an introductory product knowledge course on scaffolding systems, focusing on their types, selection criteria, and the alum-a-pole scaffolding system offered by Alum-a-Pole Corporation. It outlines various scaffolding designs, their benefits, and necessary safety considerations, while also detailing the unique features of the alum-a-pole system. The course aims to educate professionals on scaffolding essentials to enhance safety and productivity in construction settings.