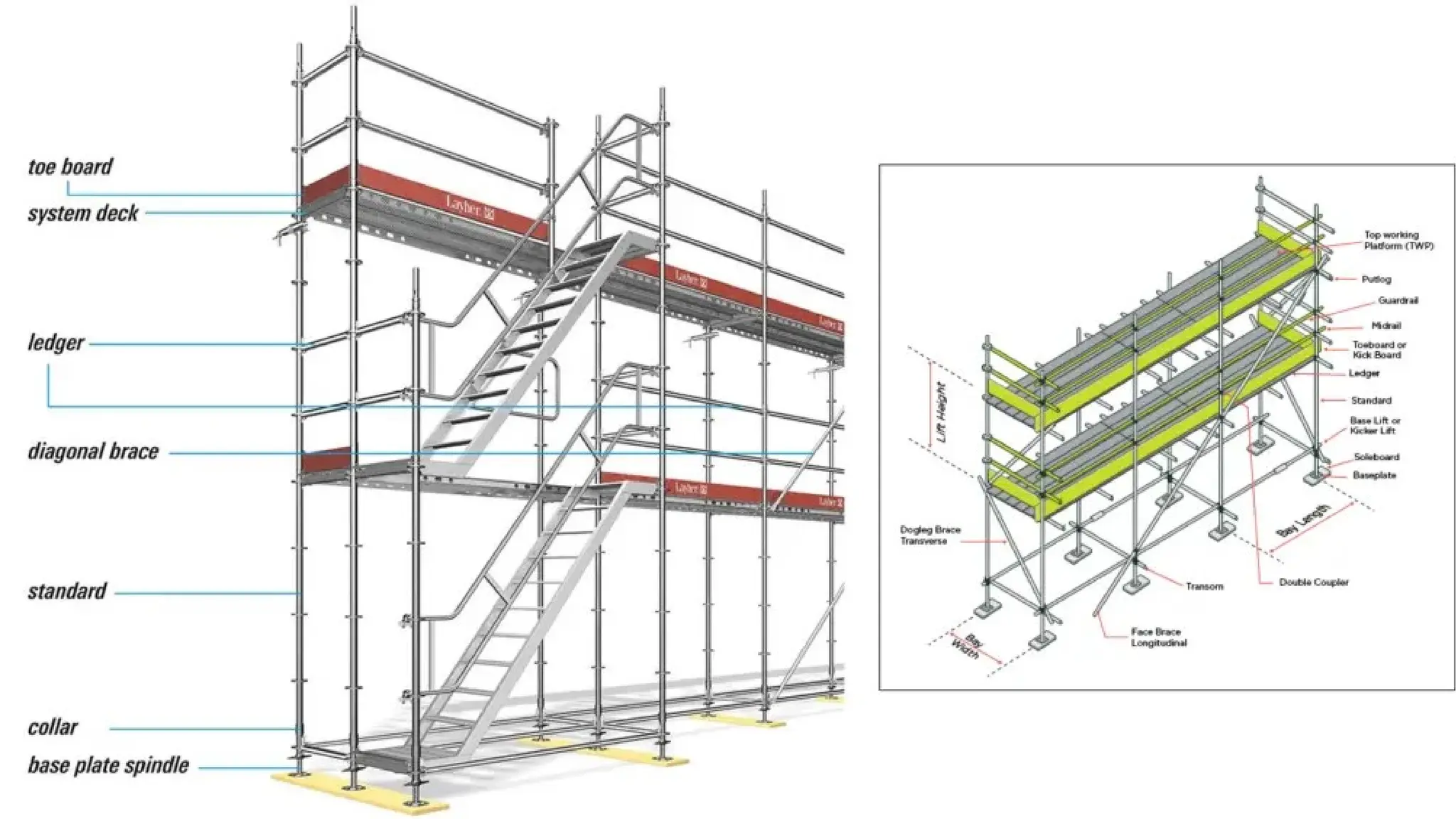

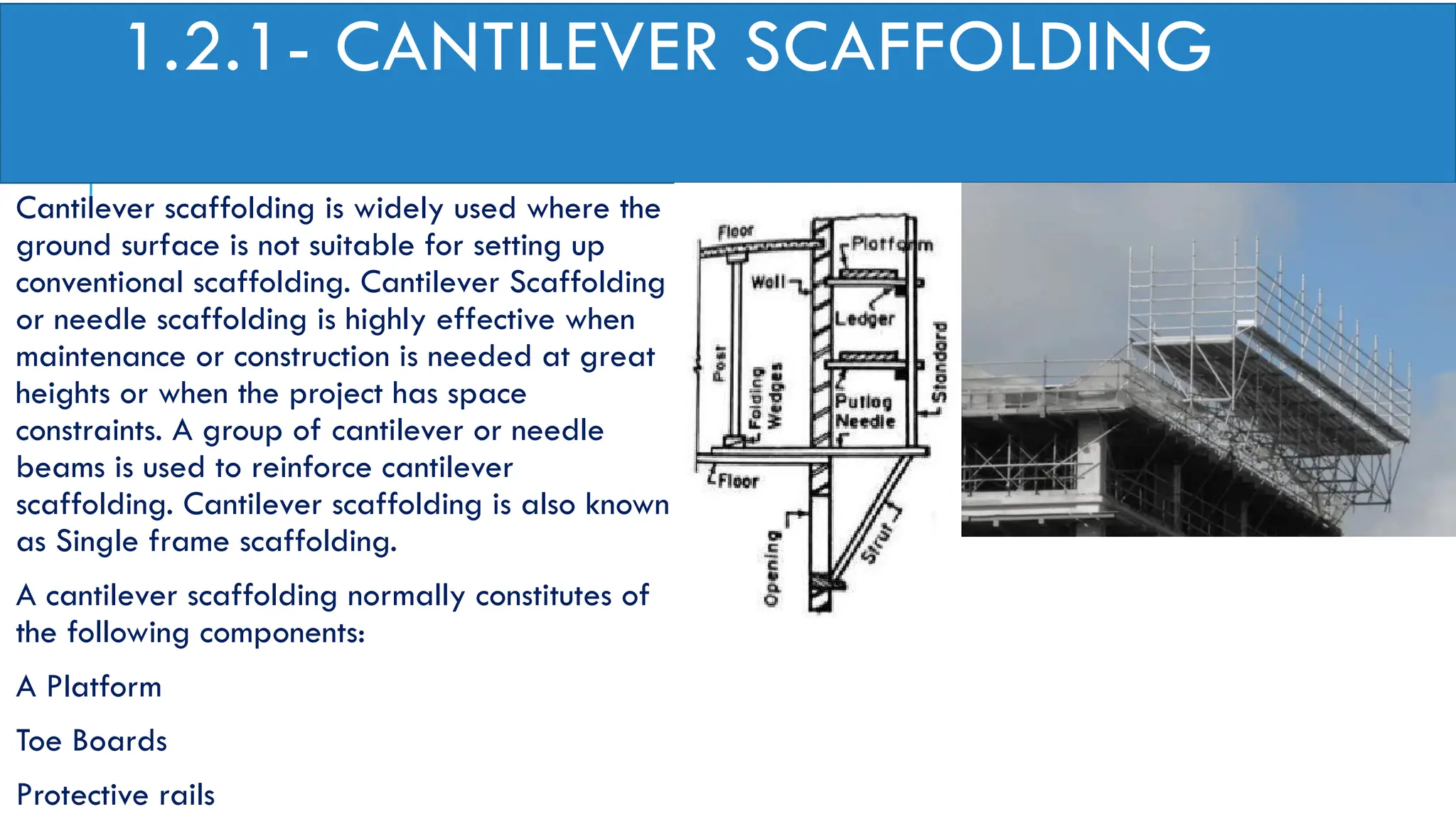

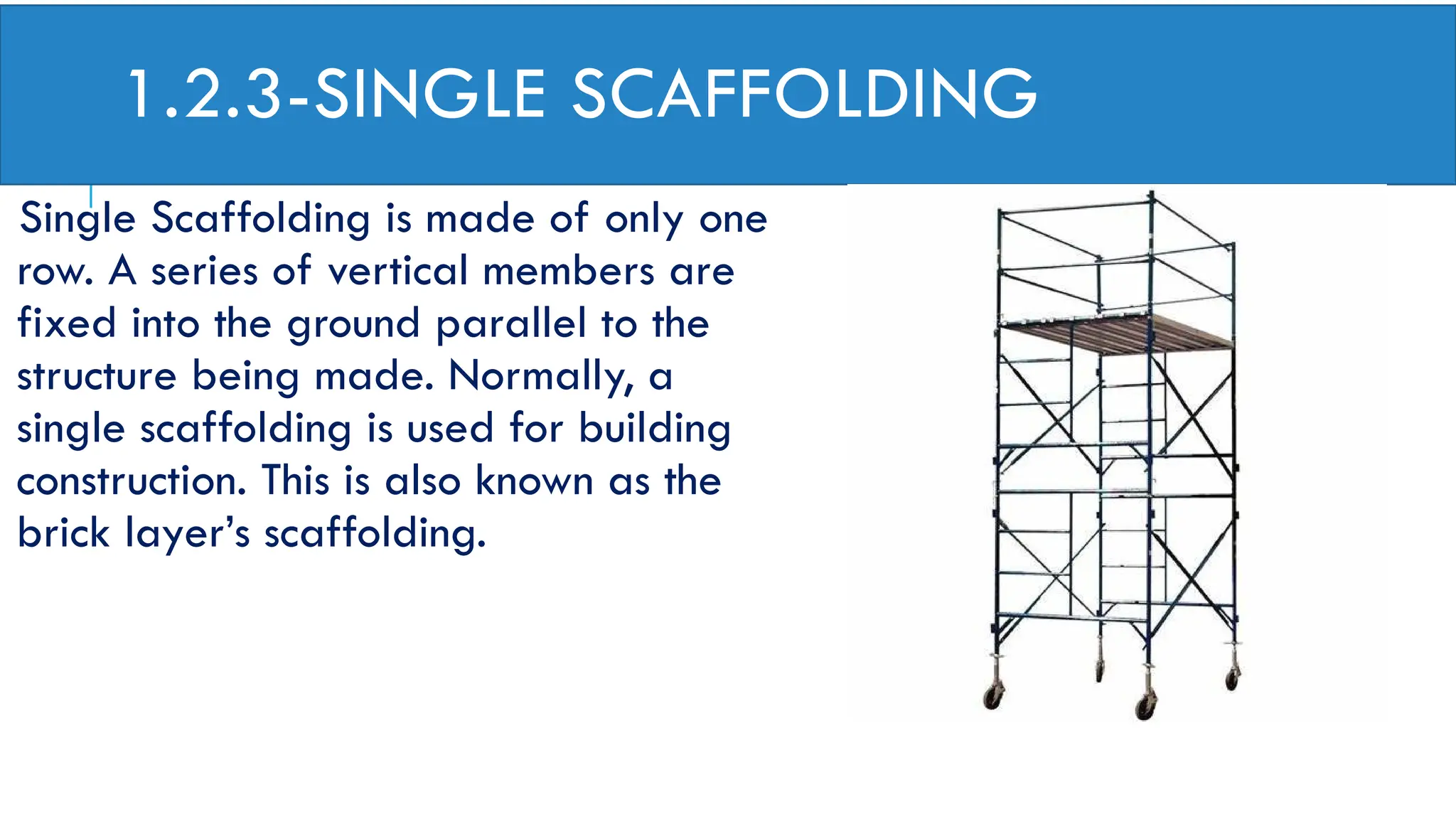

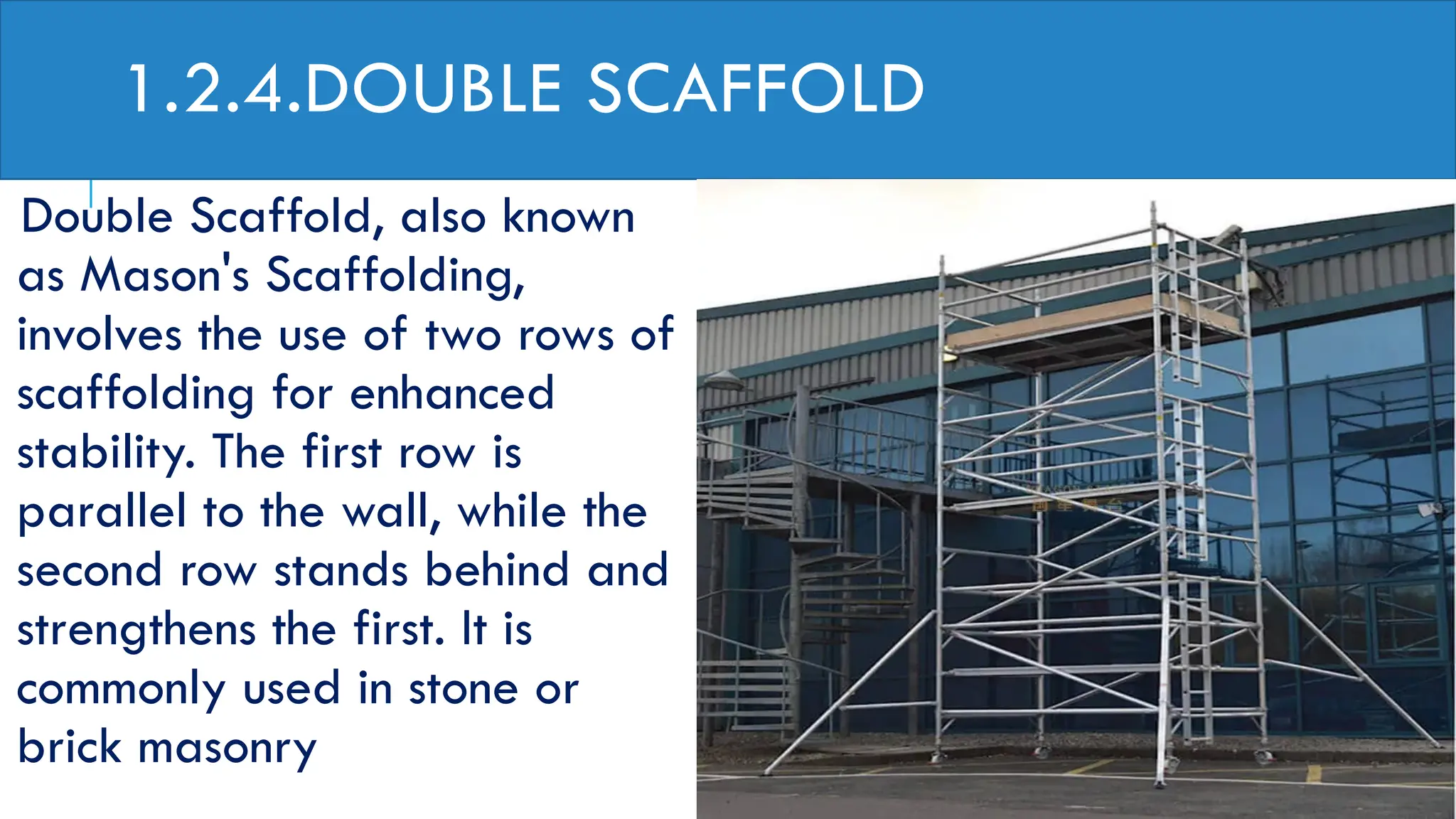

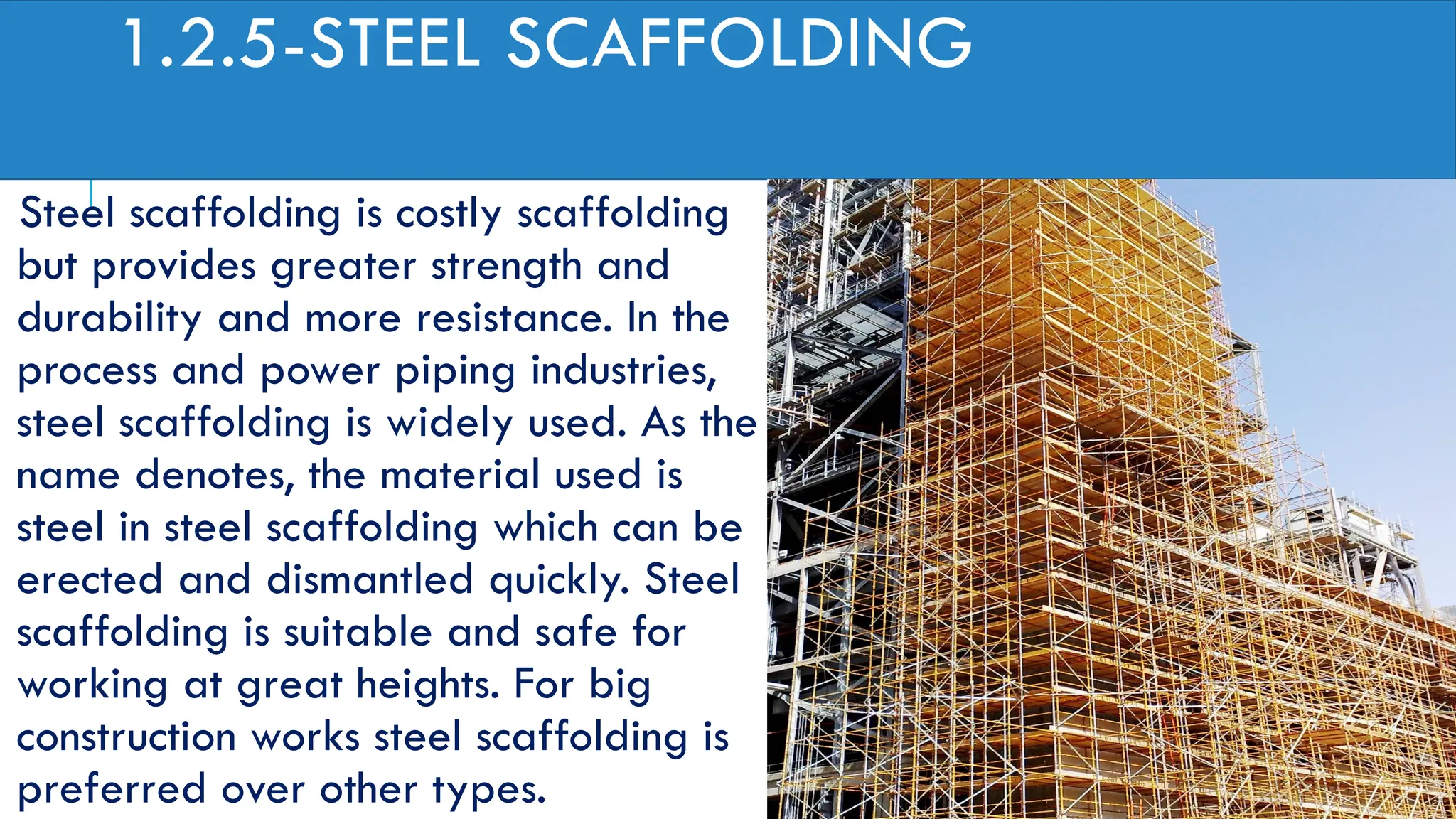

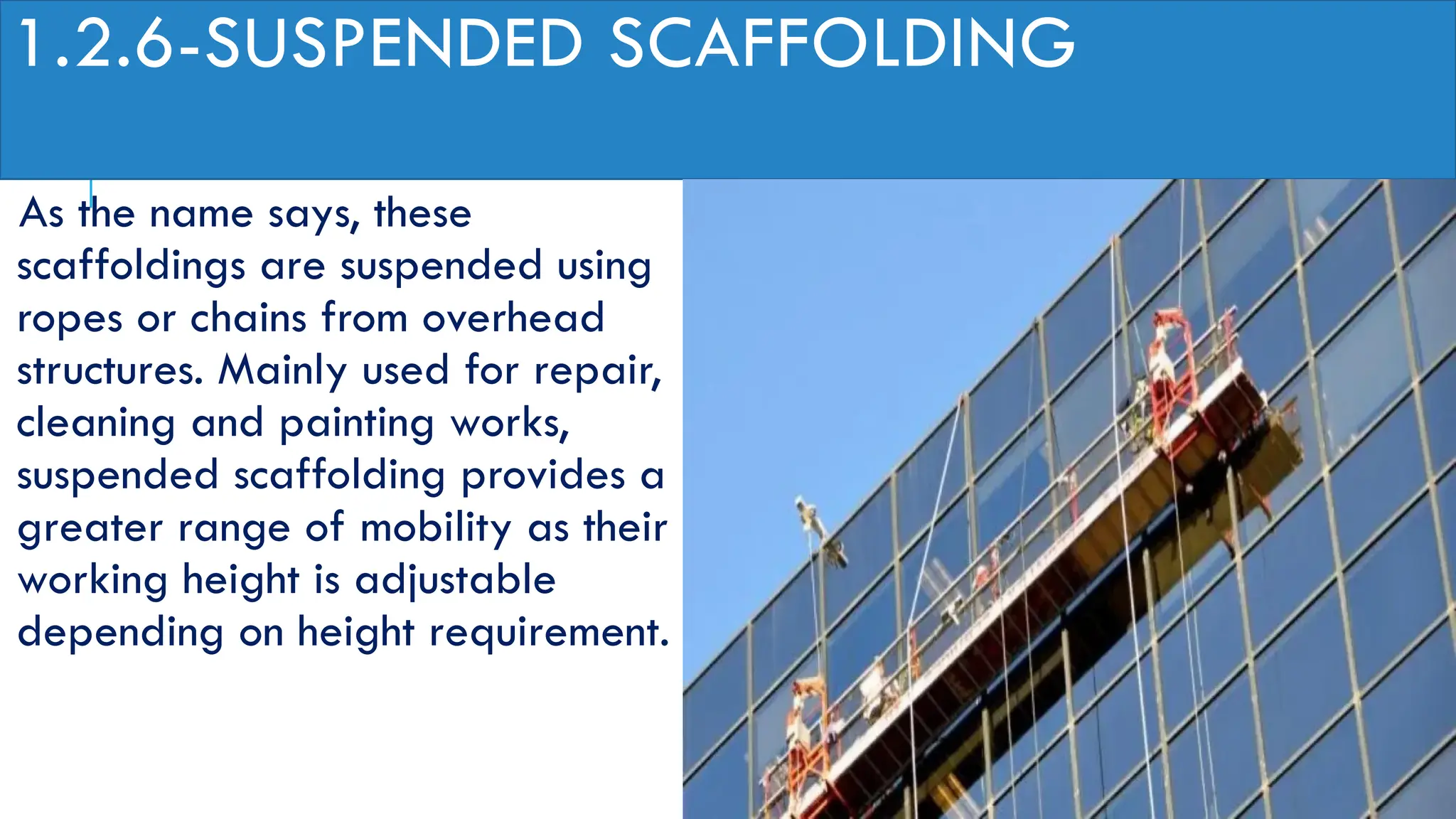

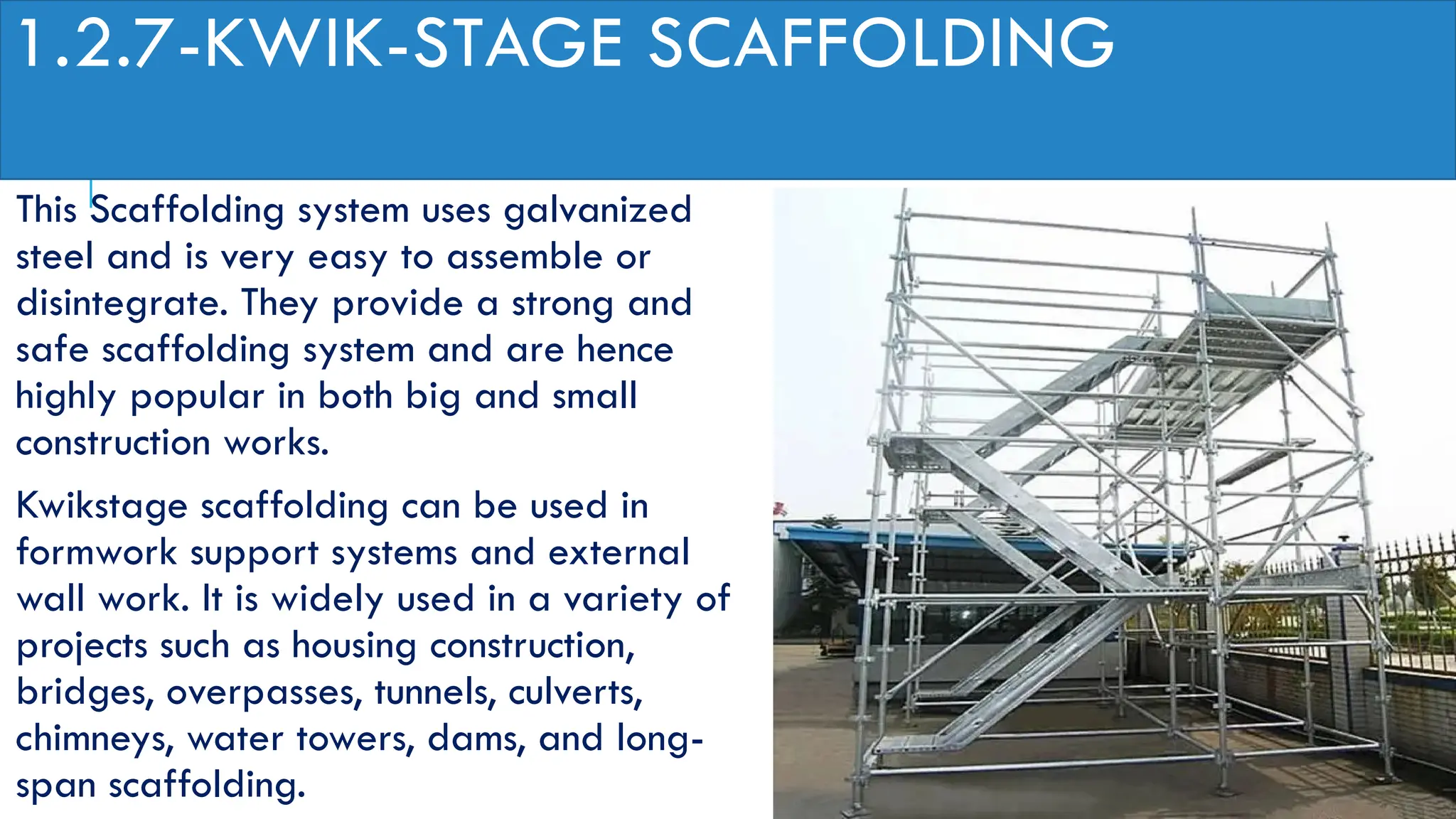

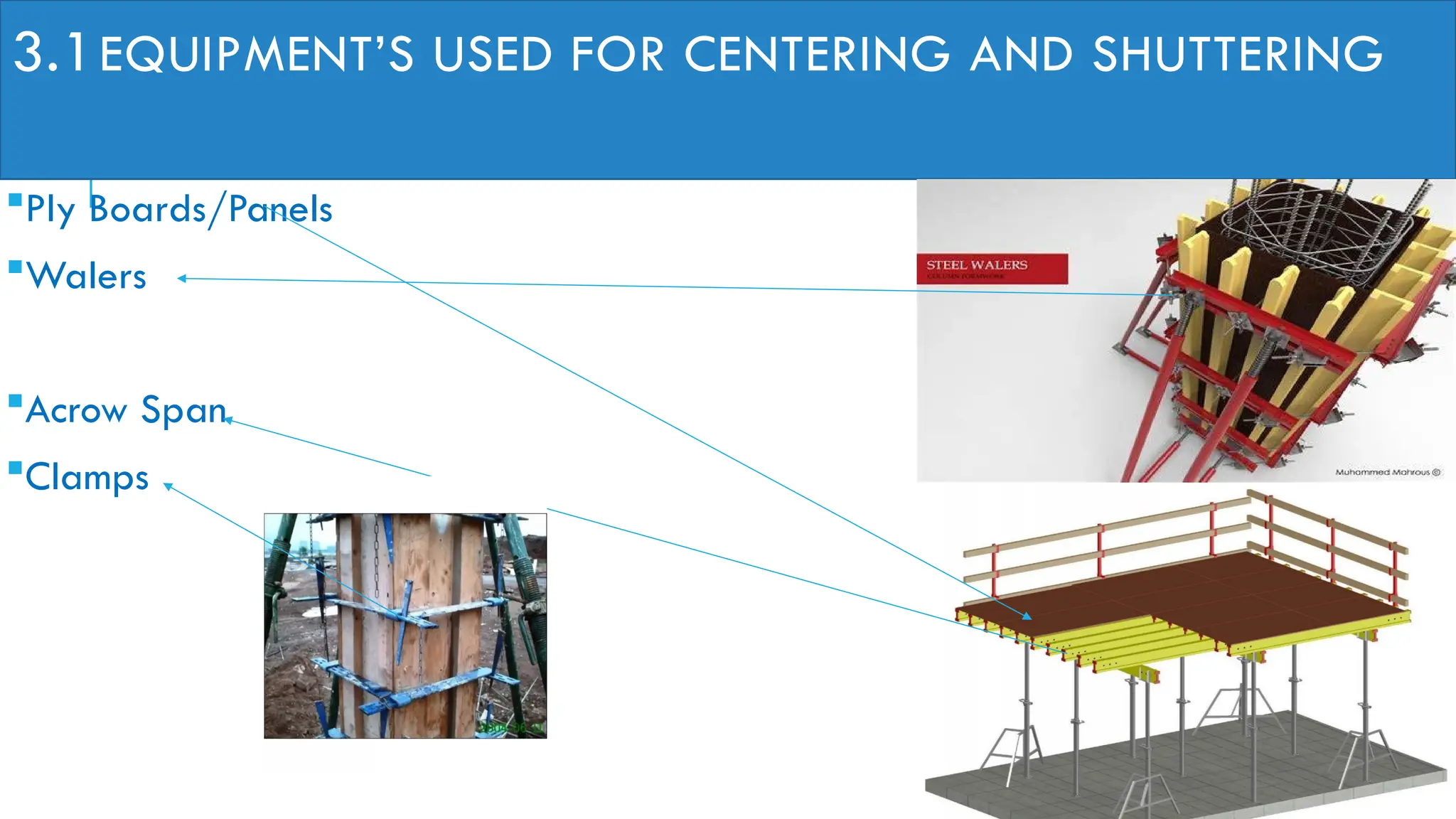

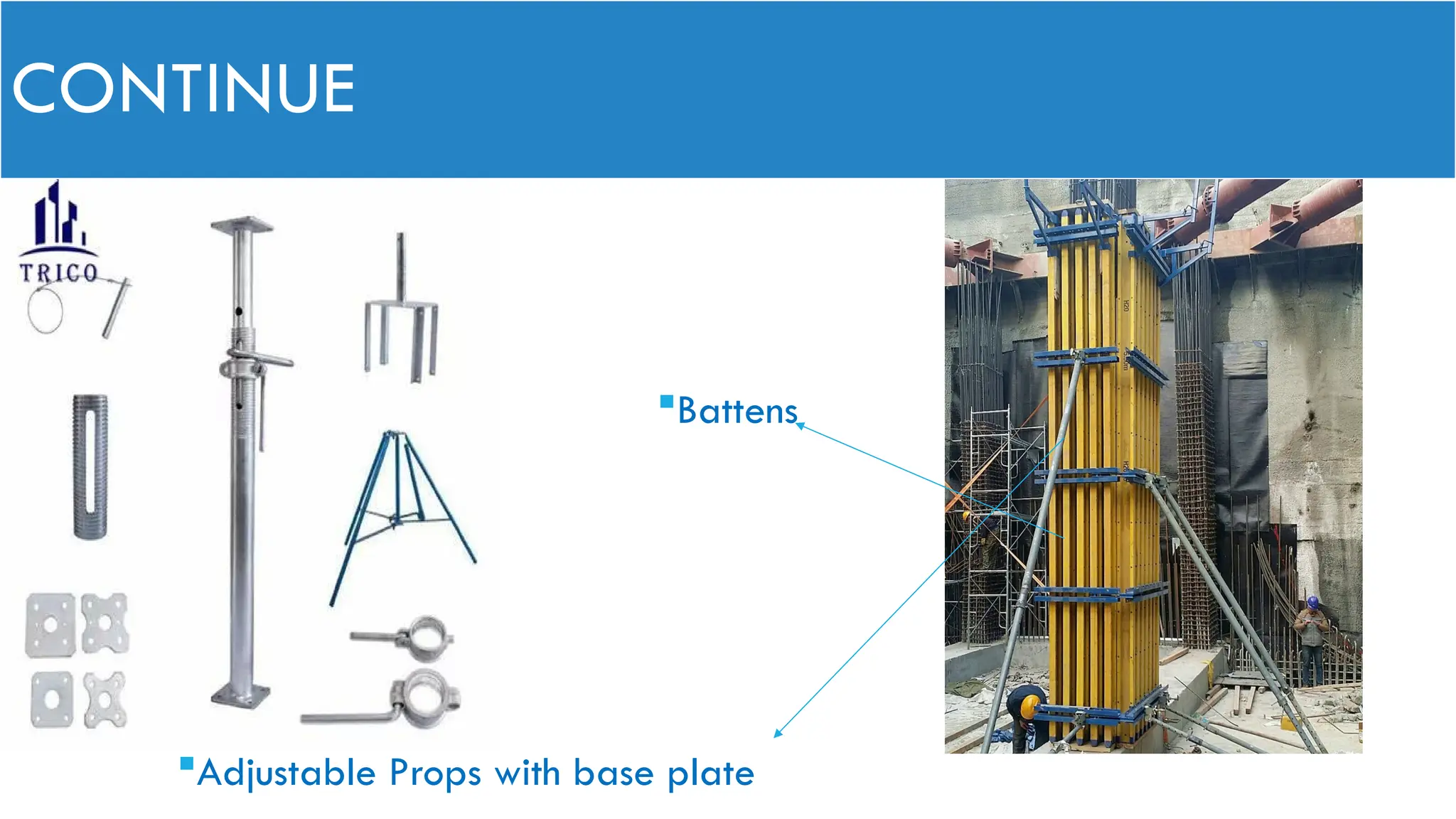

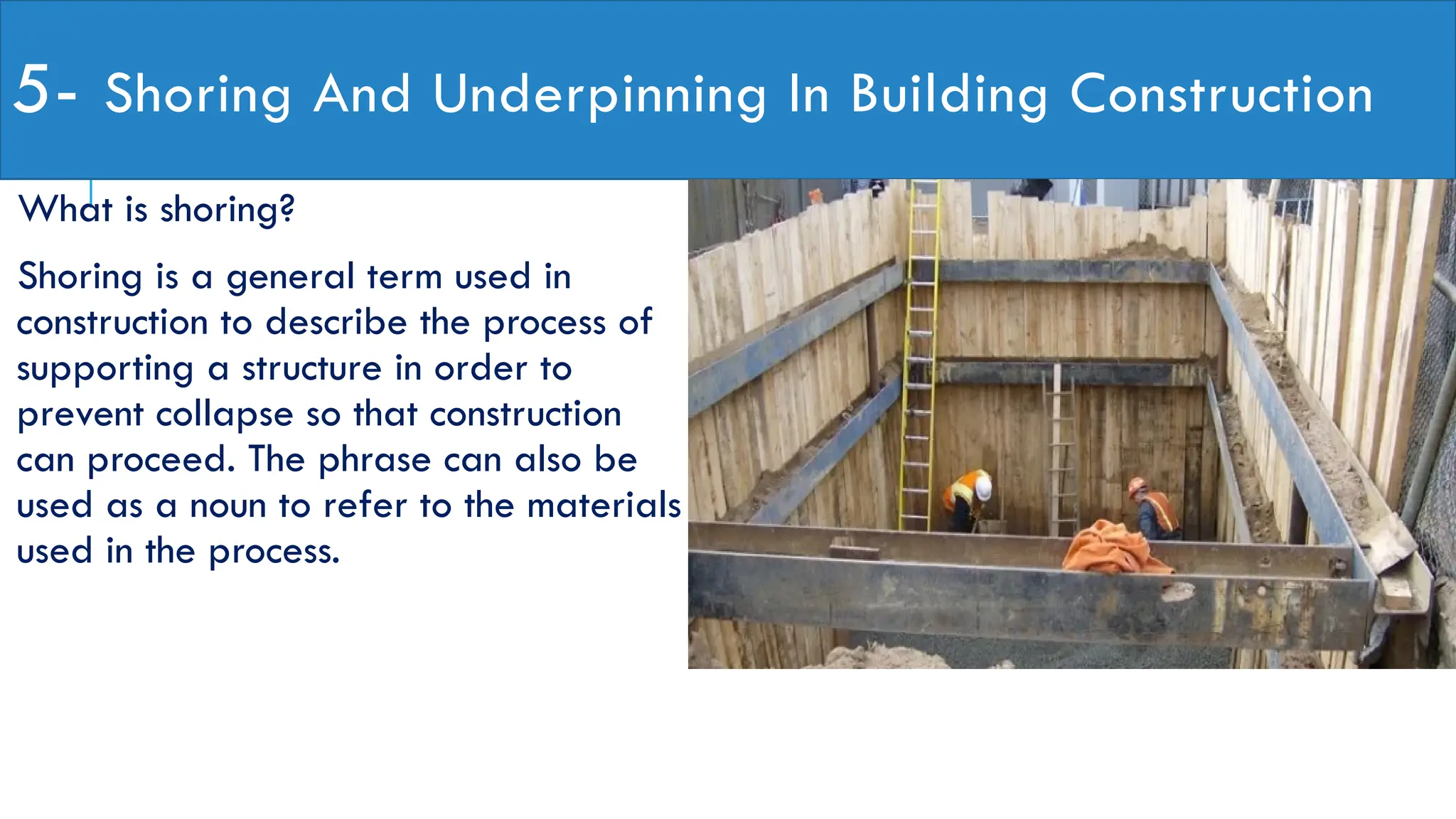

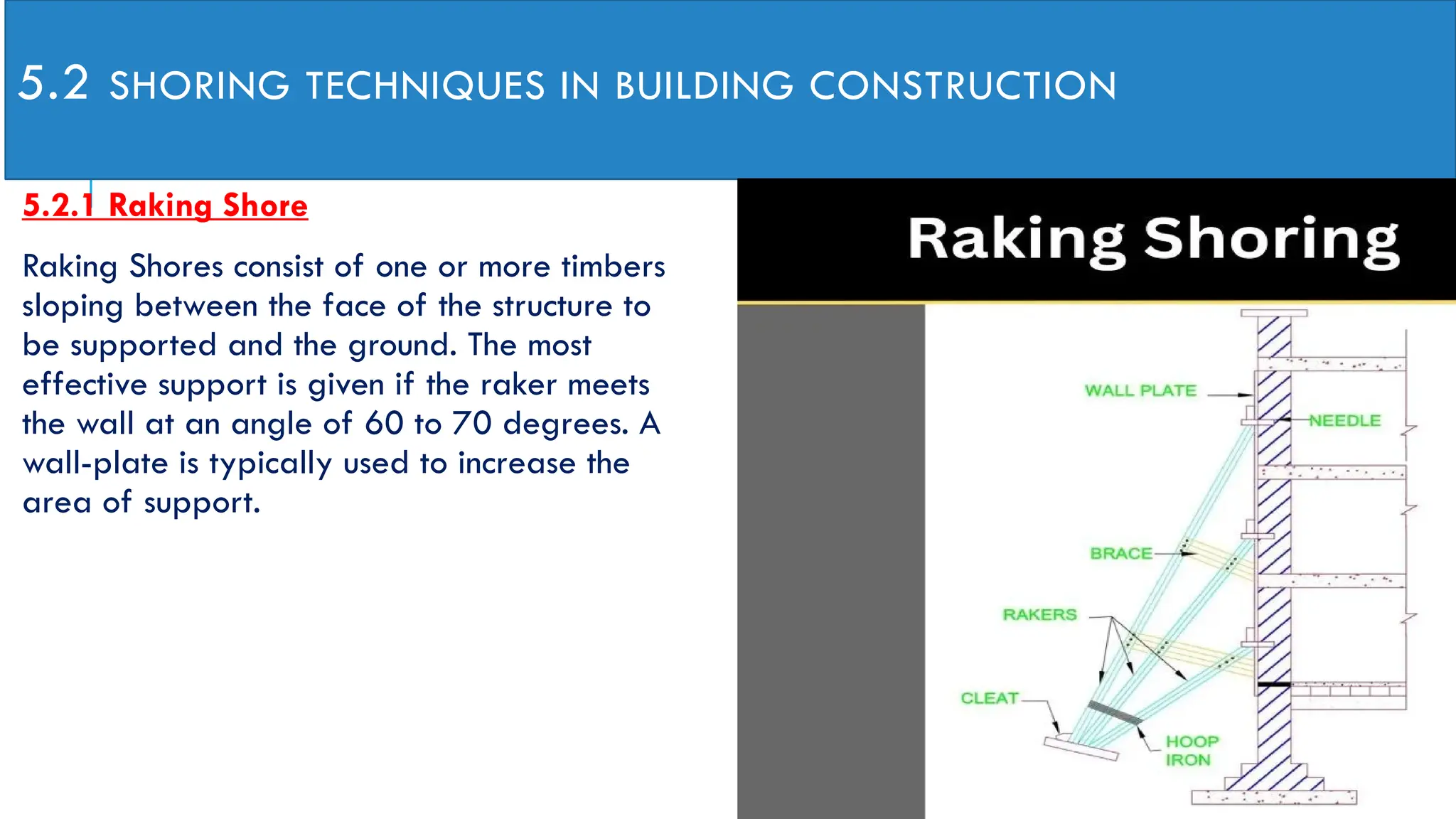

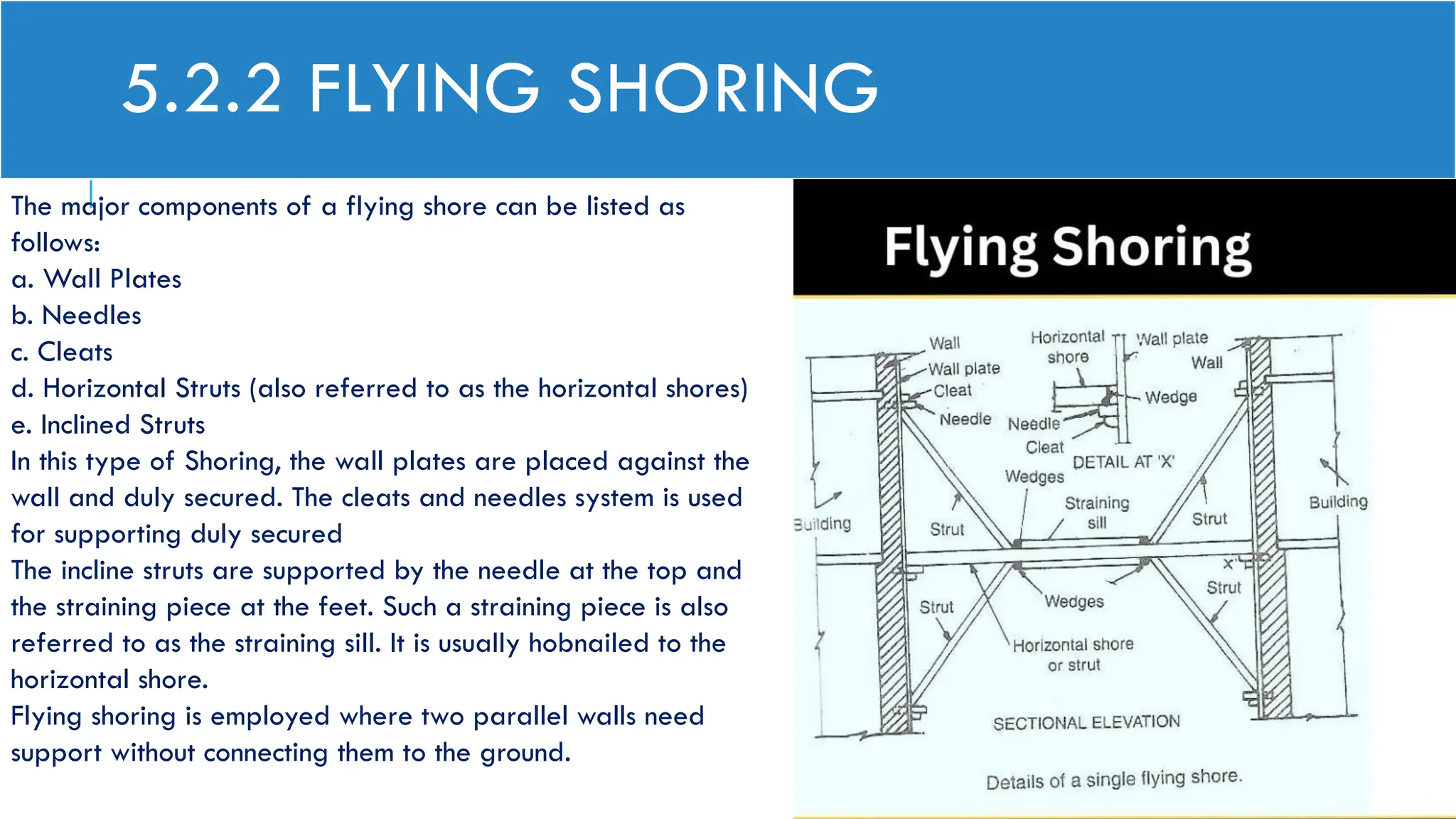

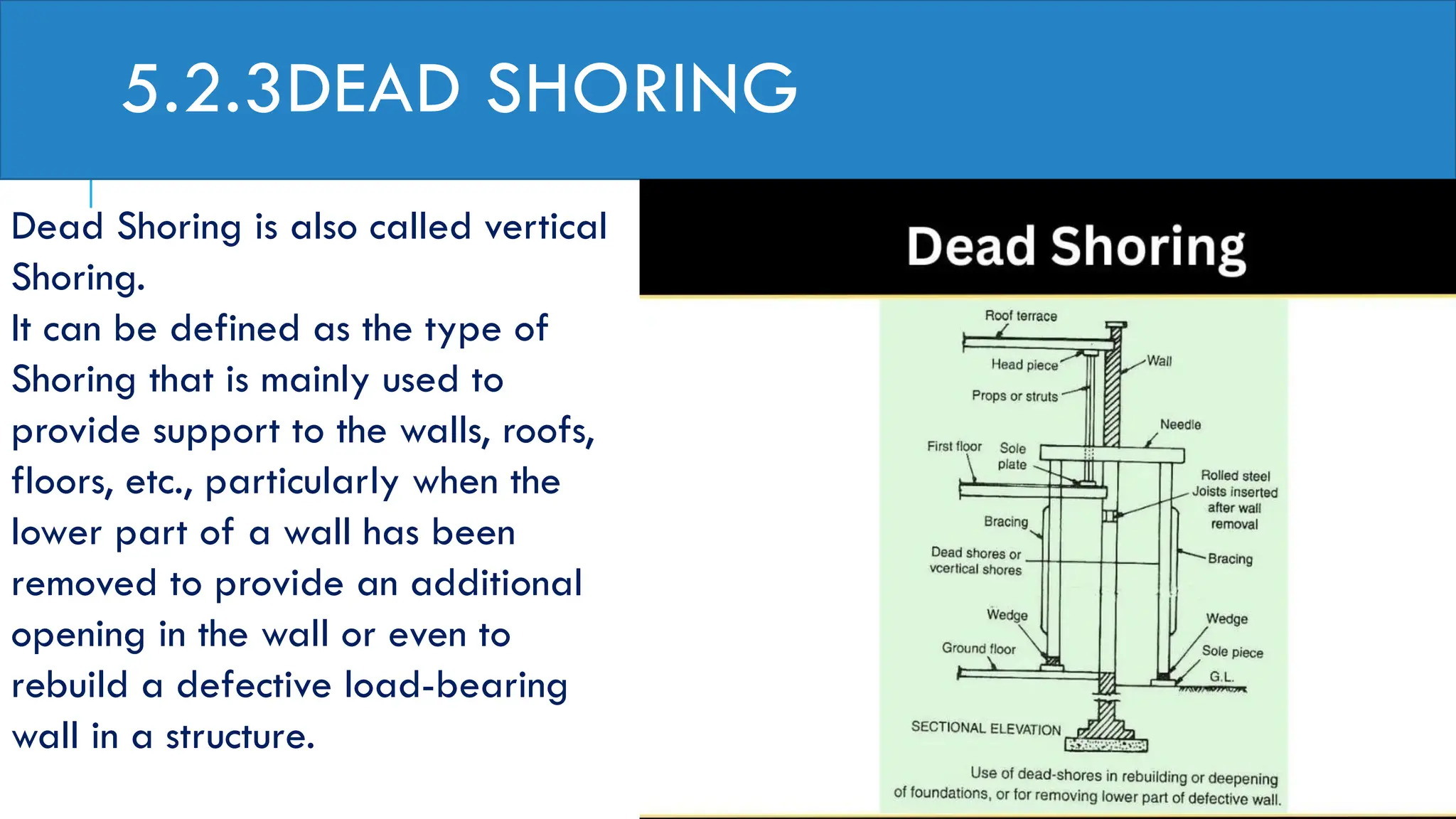

The document provides an extensive overview of scaffolding, formwork, centering, shuttering, shoring, and underpinning in construction. It details the definitions, types, components, hazards, and materials associated with scaffolding, as well as the requirements and techniques for formwork and shoring. Additionally, it discusses underpinning and its necessity in stabilizing existing structures, including methods like micropiles and jet grouting.