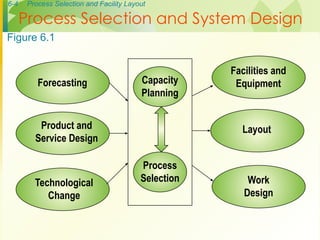

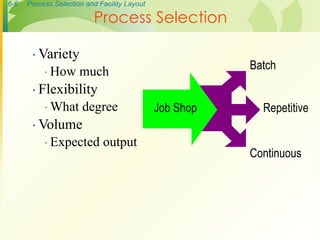

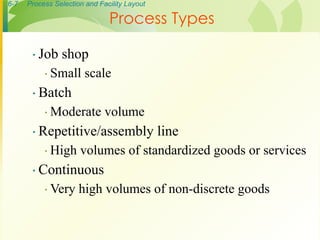

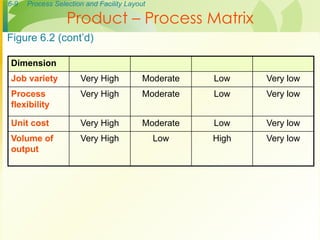

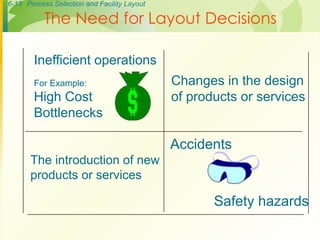

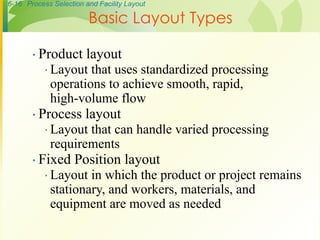

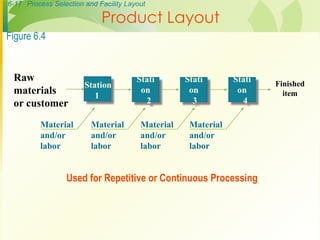

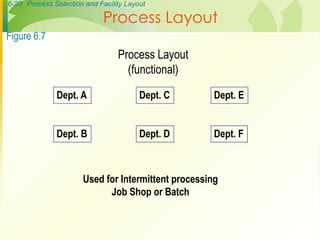

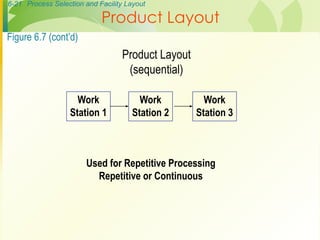

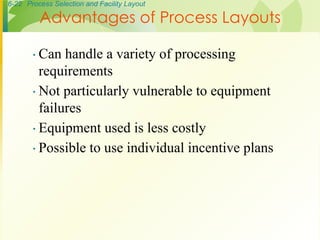

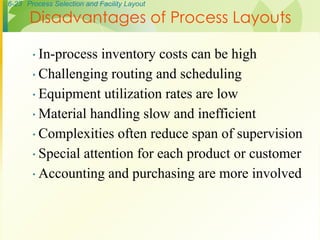

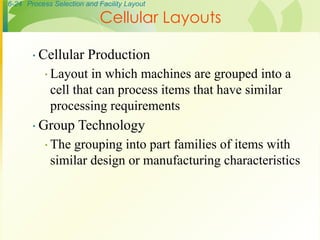

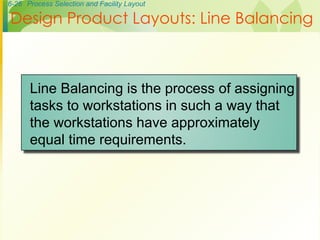

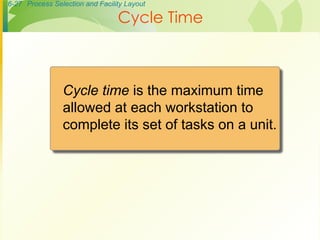

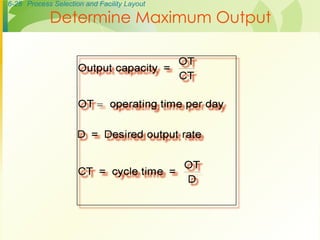

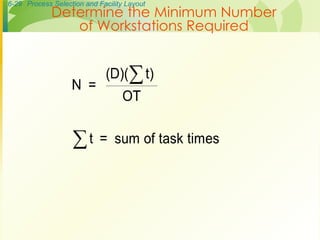

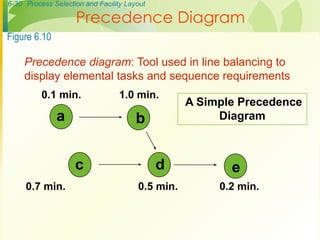

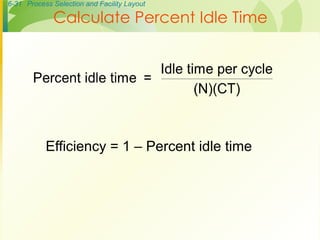

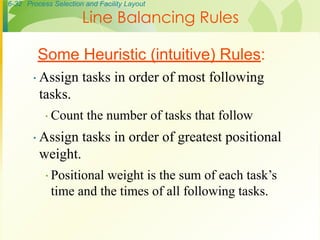

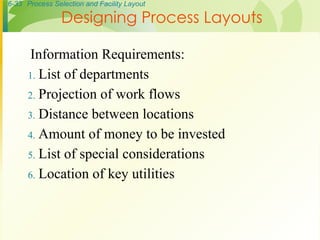

This chapter discusses process selection and facility layout. It covers determining the appropriate production process based on factors like volume and flexibility. The main types of processes are job shop, batch, repetitive and continuous. It also discusses layout types like product and process and factors to consider in layout design like space, equipment, and workflow. The chapter provides guidelines for line balancing when designing assembly line layouts and considerations for process layout design.