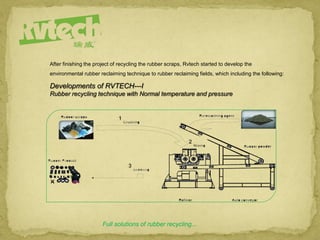

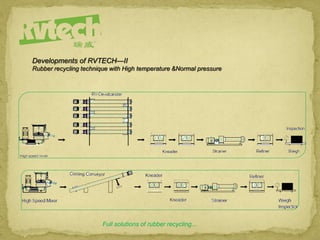

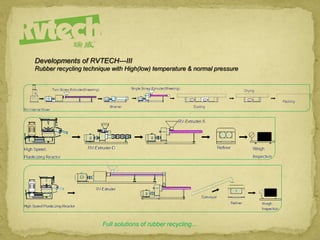

RVtech was established in 2000 as the first company to introduce rubber recycling technology using normal temperature and pressure. Since then, RVtech has developed 7 rubber recycling lines using different temperature and pressure combinations. RVtech's recycling process uses a rubber reclaiming agent to break sulfur-sulfur bonds in rubber scraps without damaging other bonds, restoring the rubber's properties without additional vulcanizing agents. This technique produces reclaimed rubber with better quality and lower costs than traditional reclaiming methods.