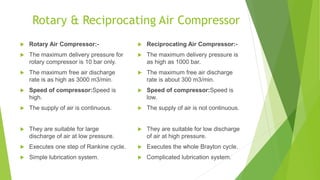

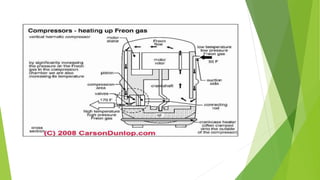

The document compares and contrasts rotary and reciprocating air compressors. Rotary compressors can deliver air at higher volumes up to 3000 m3/min but at lower maximum pressures of 10 bar. Reciprocating compressors deliver lower volumes of around 300 m3/min but at much higher maximum pressures of 1000 bar. Rotary compressors operate at higher speeds continuously while reciprocating compressors operate at lower speeds discontinuously. Hermetically sealed compressors enclose the compressor and motor in a single welded steel casing, making the unit compact and portable. They are commonly used in household appliances like refrigerators and air conditioners that require low power.