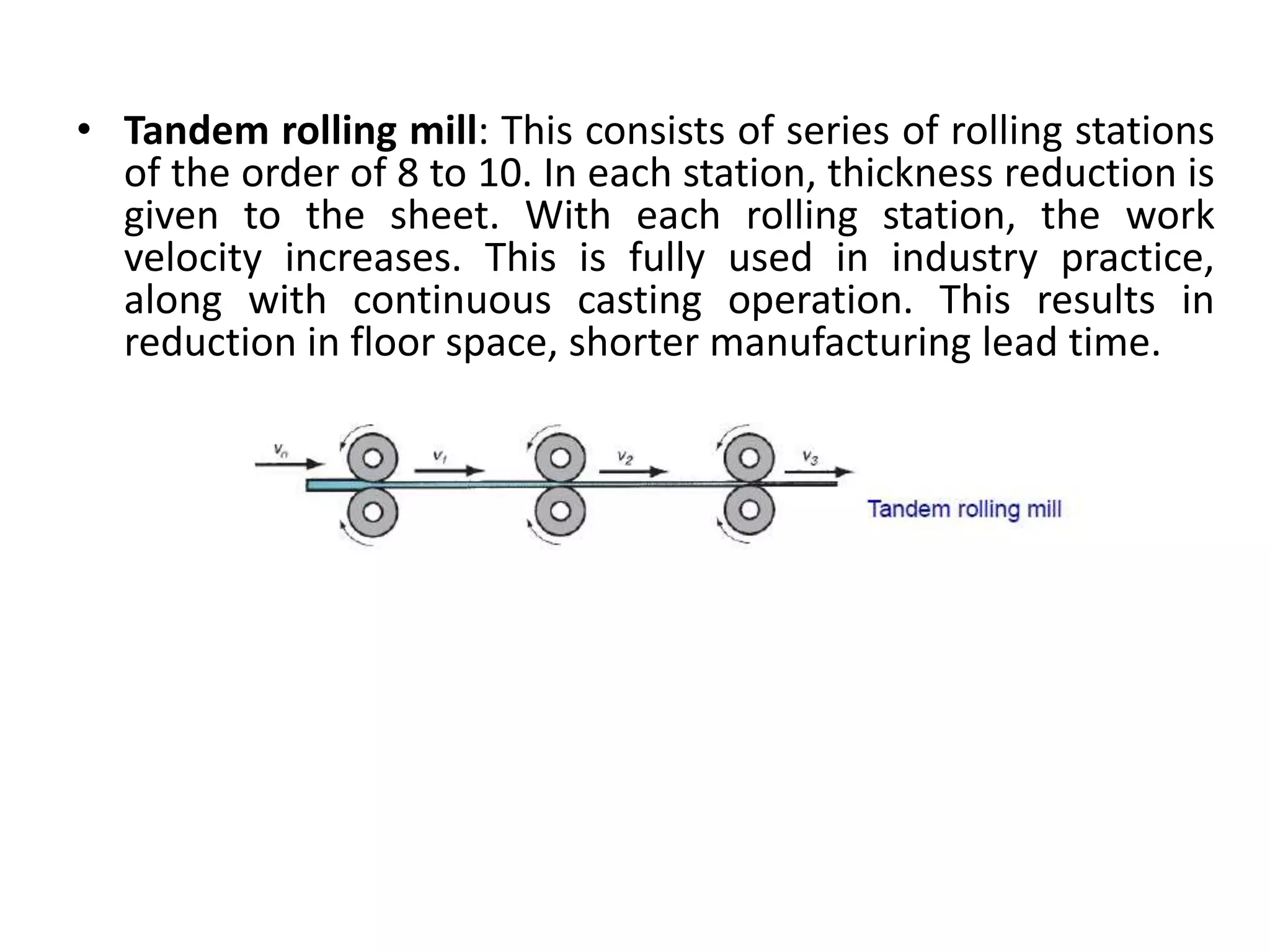

Metal forming processes take ingots, slabs, billets, and blooms produced by casting liquid metal and further process them through hot rolling, forging, or extrusion to produce materials in standard forms. Rolling is a metal forming process that reduces the thickness of metal by compressive forces from two rotating rolls. There are several types of rolling mills including two high, three high, four high, and tandem rolling mills. Blooms are rolled into structural shapes, billets into bars and rods, and slabs into plates and sheets for uses like shipbuilding and bridges.