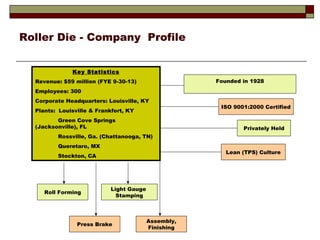

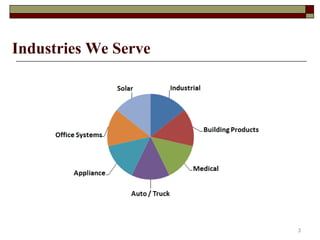

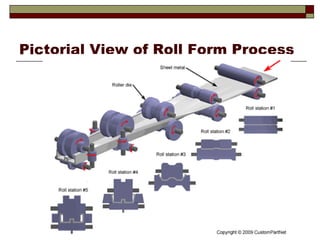

Roller Die, established in 1928 and headquartered in Louisville, KY, is a privately held company specializing in roll forming and related processes, generating $59 million in revenue with 300 employees. They provide technical expertise and manufacturing services across various materials and industries, emphasizing lean manufacturing and ISO 9001:2000 certification. The roll forming process allows for precise shaping of diverse materials, making it suitable for both decorative and structural applications.