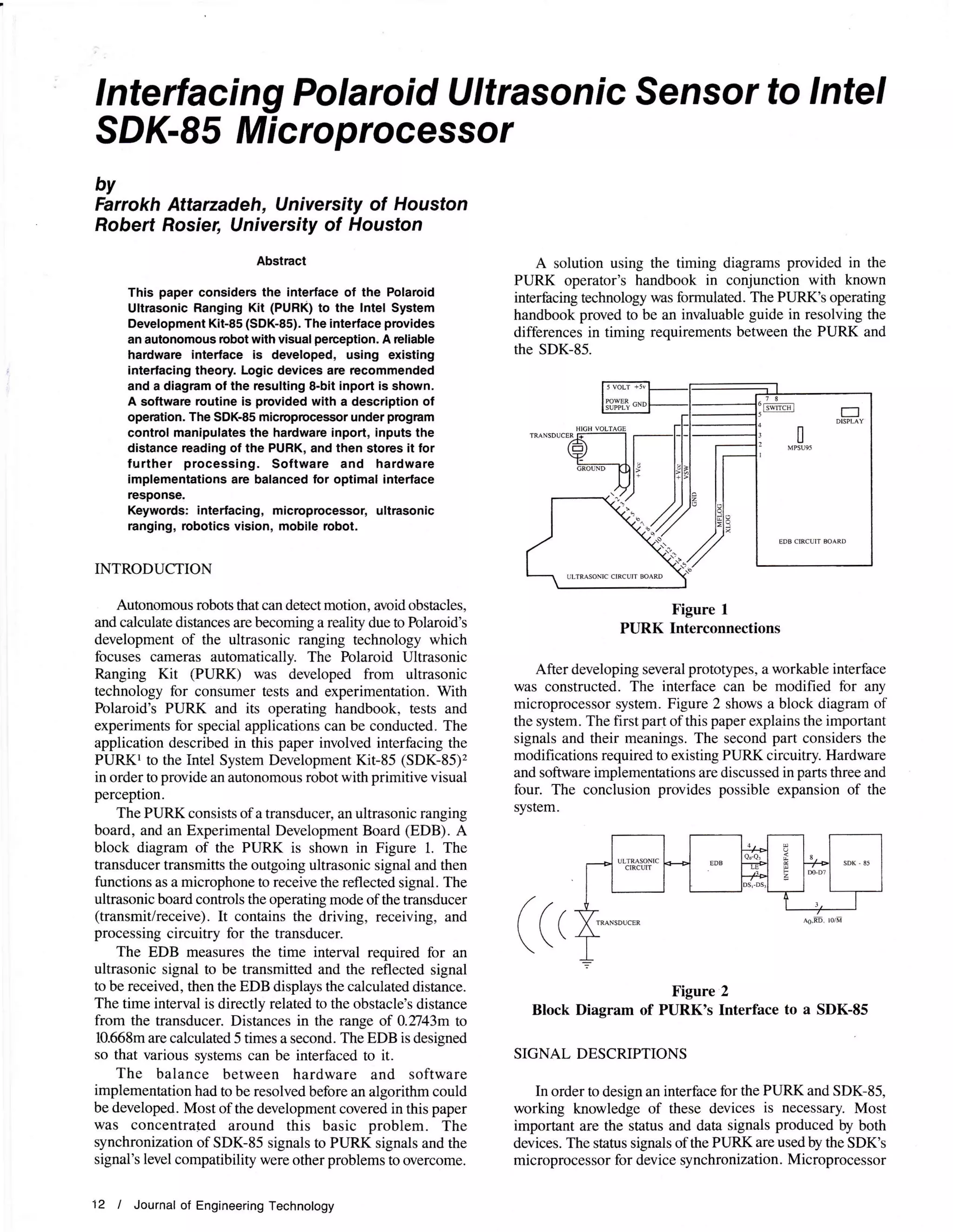

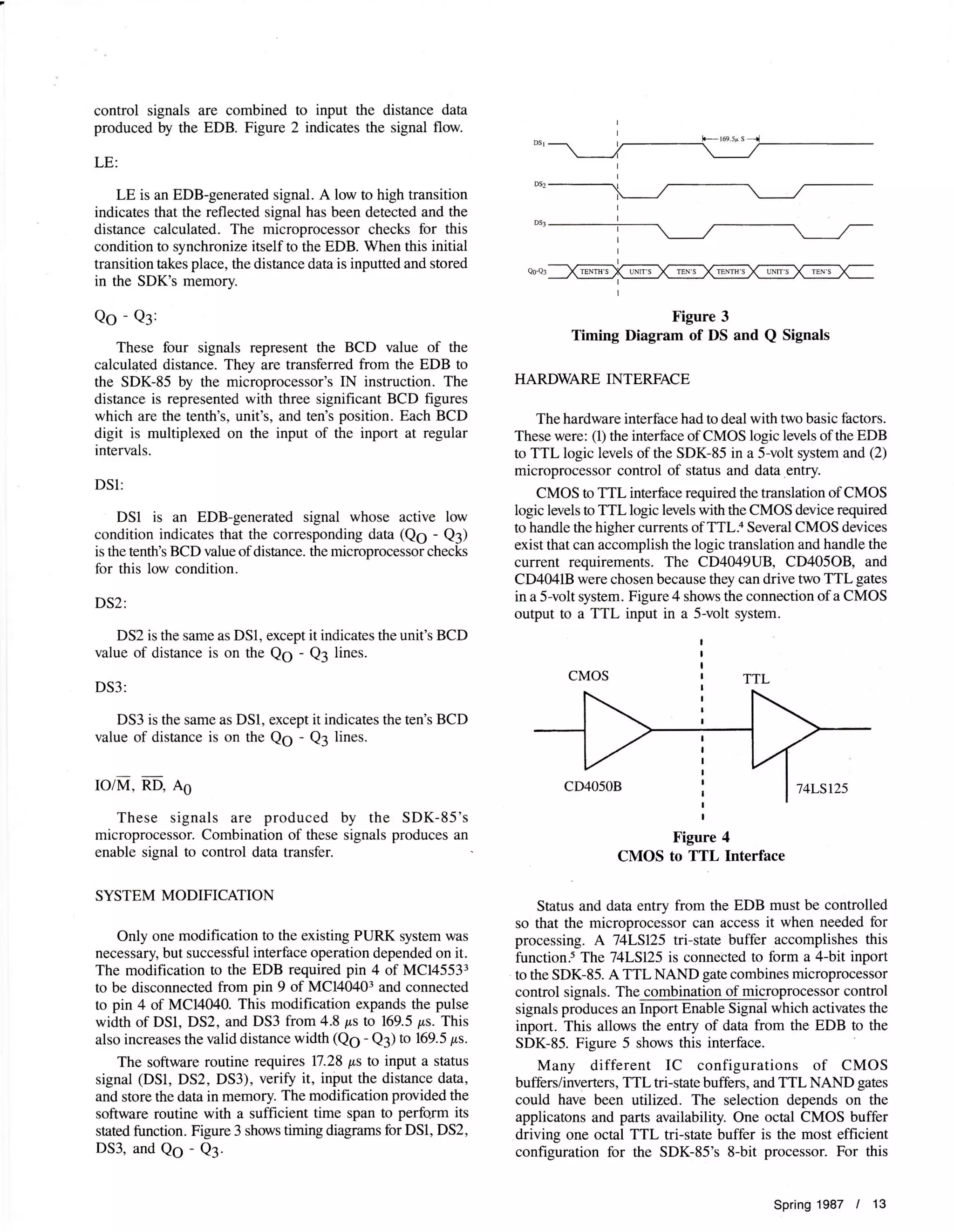

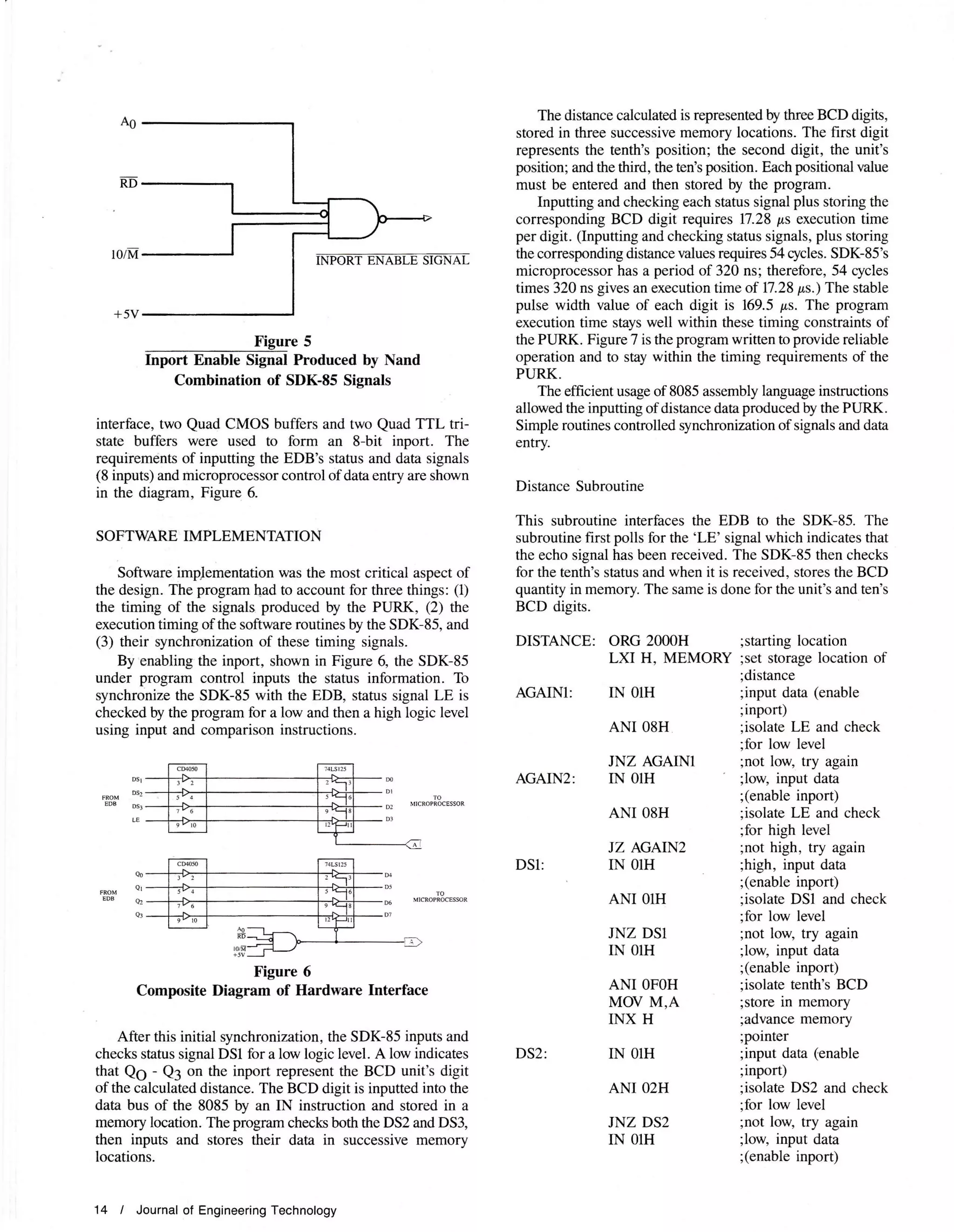

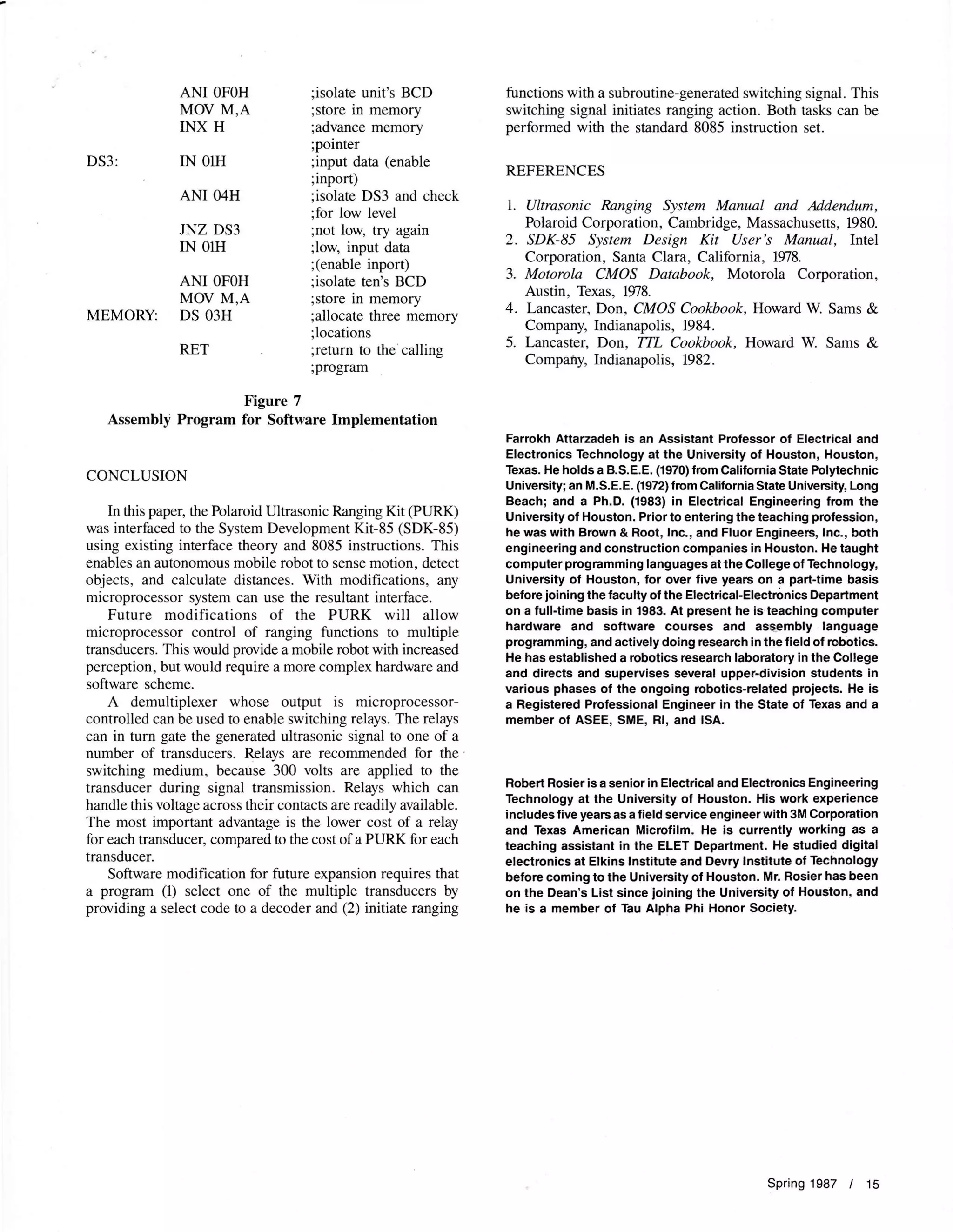

This document summarizes the interfacing of a Polaroid Ultrasonic Ranging Kit (PURK) to an Intel System Development Kit-85 (SDK-85) microprocessor to provide distance sensing capabilities for an autonomous robot. The interface required modifying the PURK circuitry to synchronize its signals with the SDK-85. A hardware interface was developed using CMOS and TTL logic devices to translate signal levels. Software was also developed to input the PURK's distance readings, synchronizing with its status signals under microprocessor control. The interface allows the microprocessor to access the PURK's distance measurements for further processing and autonomous robot control.