1. Cocoa fermentation involves both anaerobic and aerobic phases. During the initial anaerobic phase, yeast converts pulp sugars into alcohol and lactic acid is formed. In the later aerobic phase, acetobacter bacteria transform the alcohol into acetic acid which penetrates the bean.

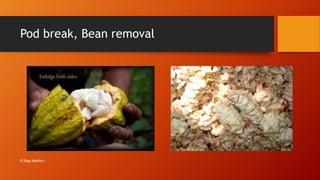

2. Cocoa pods are harvested twice annually by cutting from trees, breaking open, extracting seeds, and allowing seeds to ferment for 2-8 days before drying in the sun.

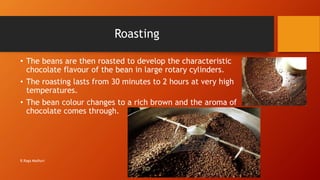

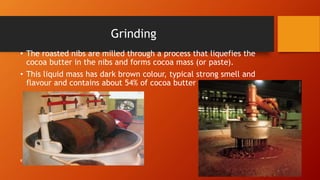

3. After drying, cocoa beans undergo processing including cleaning, roasting, grinding, and pressing to produce cocoa butter and cocoa powder which are used to make chocolate and other products.