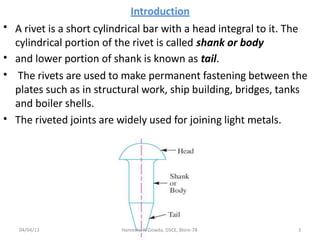

1. Riveted joints are used to join metal plates through a process where rivets are inserted through holes in overlapping or abutting plates and then clenched on the back to form a permanent fastening.

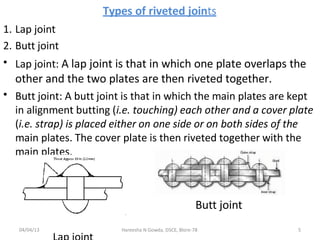

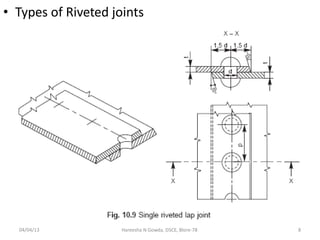

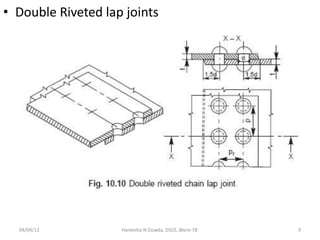

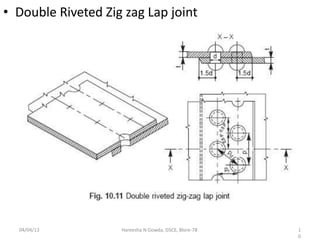

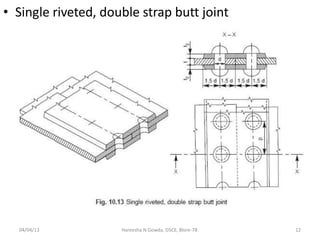

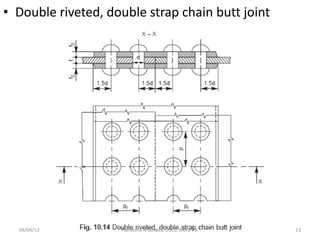

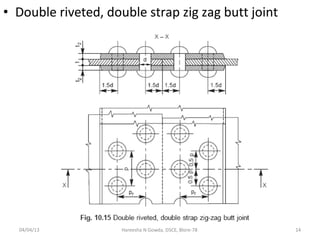

2. There are two main types of riveted joints: lap joints, where one plate overlaps the other, and butt joints, where plates are placed end to end with a cover plate attached.

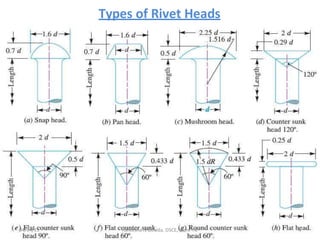

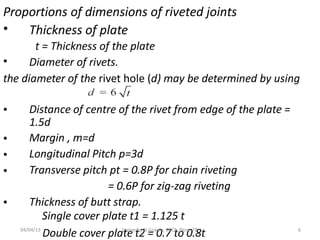

3. Key terms used to describe riveted joints include pitch (distance between rivet centers), margin (distance from rivet center to plate edge), and transverse and diagonal pitch for zigzag patterns. Proportions for rivet sizing and joint dimensions are also provided.