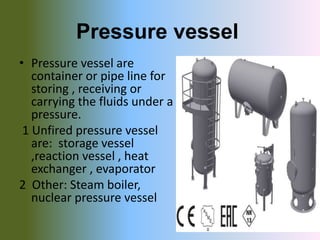

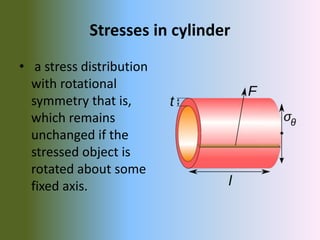

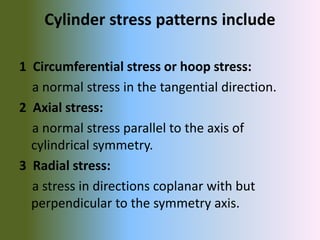

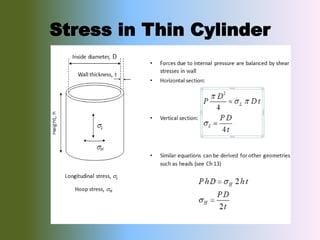

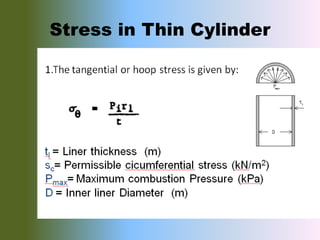

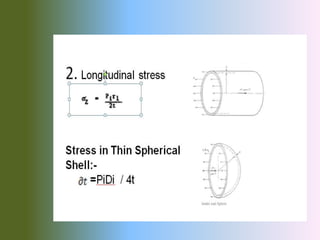

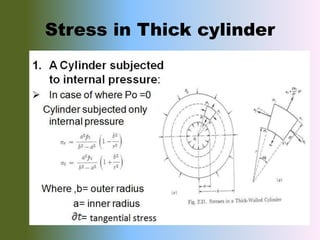

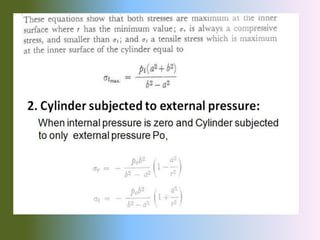

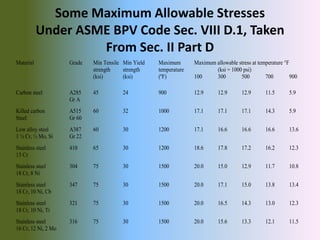

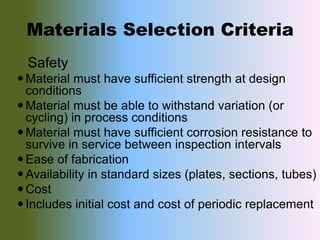

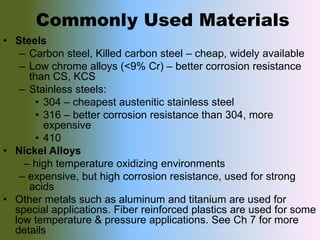

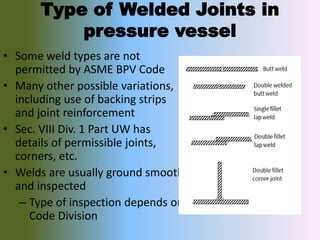

This document discusses stresses in pressure vessels. It describes how cylindrical pressure vessels experience circumferential, axial, and radial stresses. Thick cylinders have non-uniform stress distributions while thin cylinders have uniform stresses. Materials like carbon steel, stainless steel, and alloys are used in pressure vessels depending on factors like strength, corrosion resistance, cost and fabrication ease. Welded joints must meet ASME BPV Code standards. Failure analysis theories include maximum principal stress, maximum shear stress, and maximum strain energy.