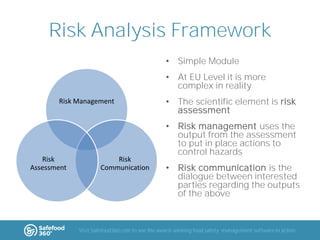

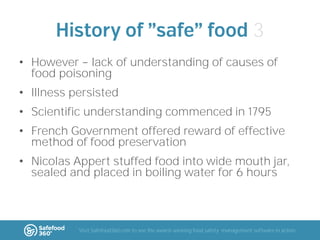

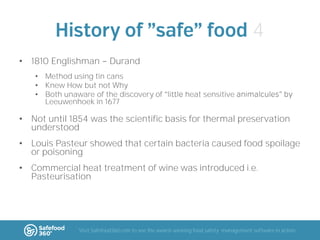

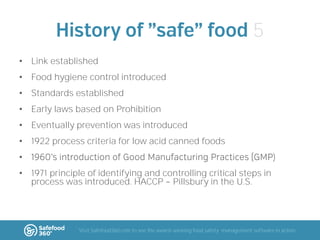

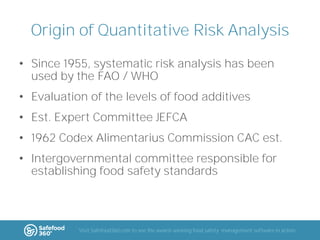

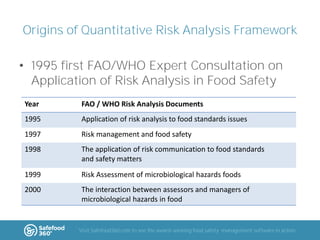

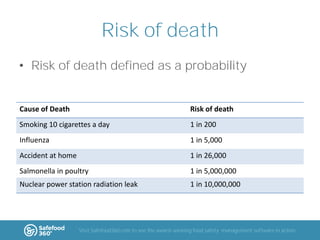

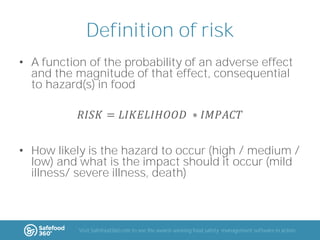

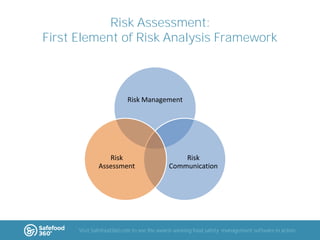

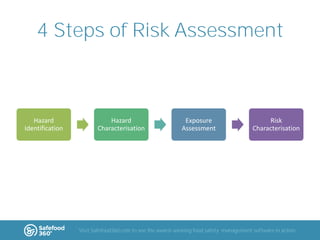

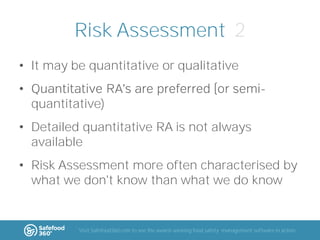

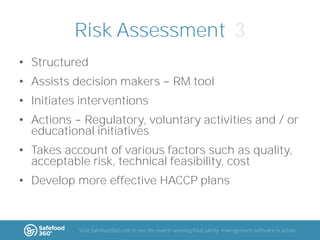

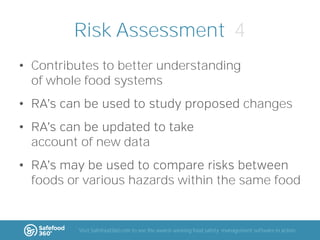

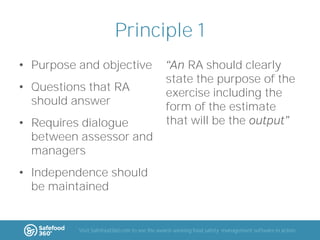

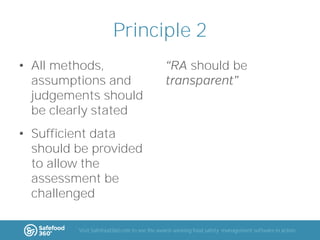

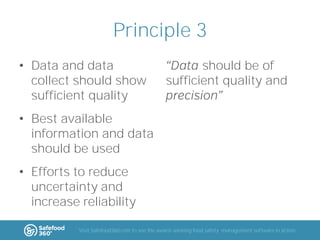

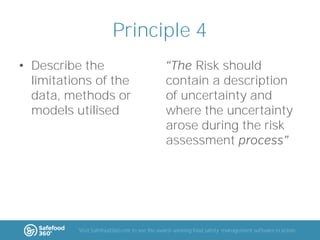

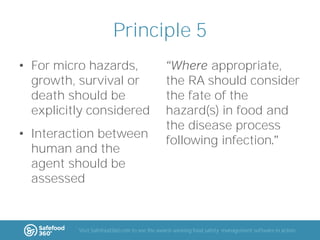

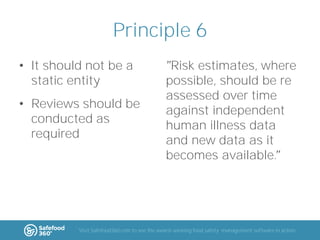

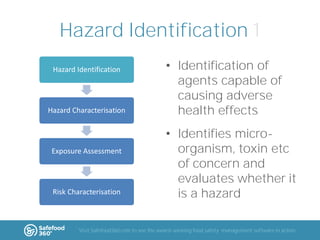

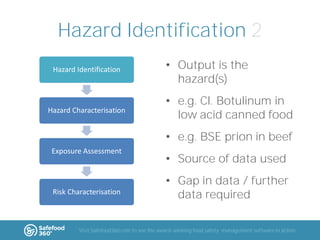

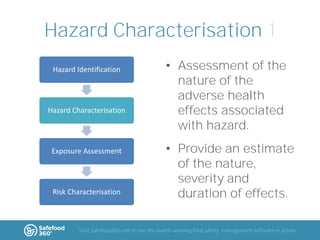

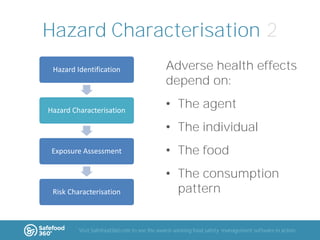

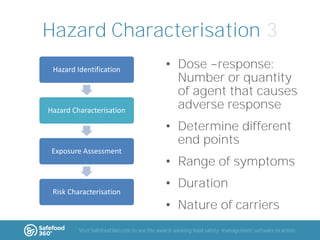

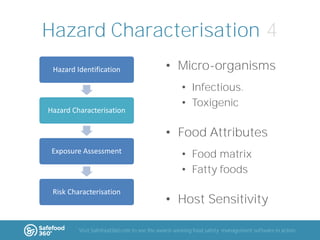

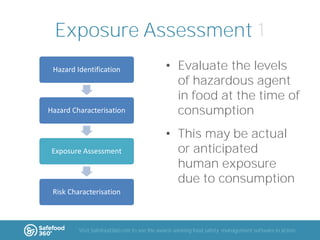

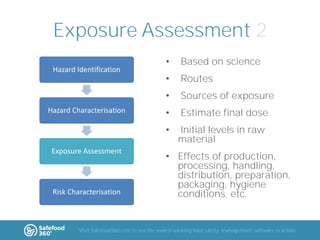

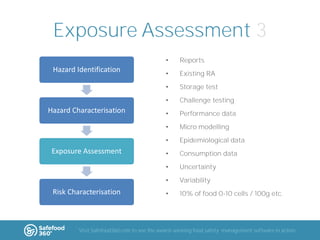

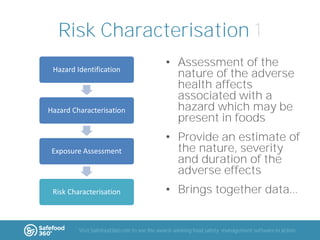

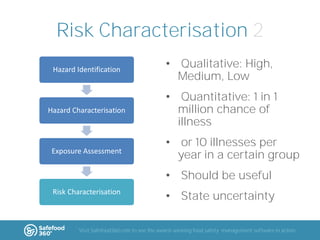

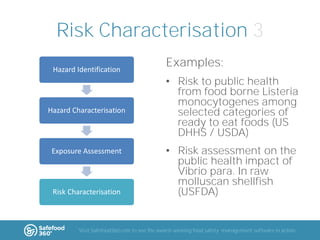

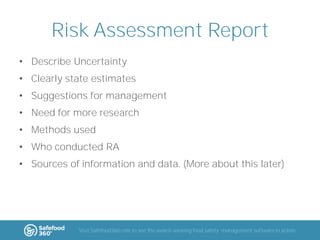

The document outlines the framework and importance of food safety risk analysis, highlighting its goal to reduce food-borne illnesses by addressing hazards throughout the food chain. It discusses the components of risk assessment, risk management, and risk communication, as well as the evolution of food safety practices and the significance of scientifically informed decision-making. Additionally, it emphasizes the necessity of identifying and evaluating hazards, managing risks, and communicating effectively to ensure public health and safety in food consumption.