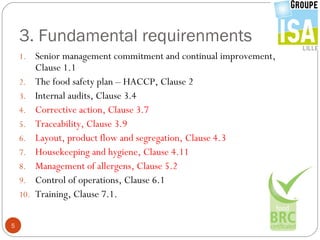

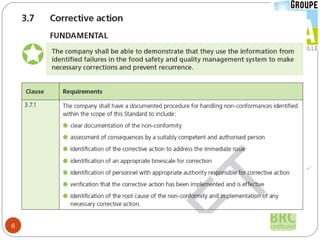

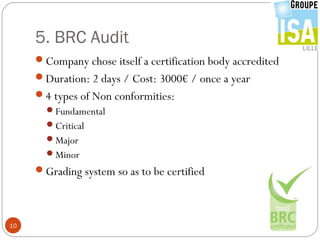

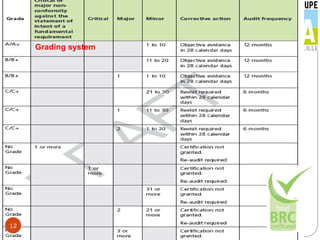

The Global Standard British Retail Consortium (BRC) was created in 1998 by British retailers to strengthen food safety standards for private label products following the BSE crisis. It has five key requirements: senior management commitment, food safety plans, auditing, corrective actions, and traceability. Audits evaluate compliance and are conducted annually, resulting in one of four grades. Audit reports detail food safety controls and non-conformities, and certification provides credibility for over 14,000 suppliers across 100 countries.