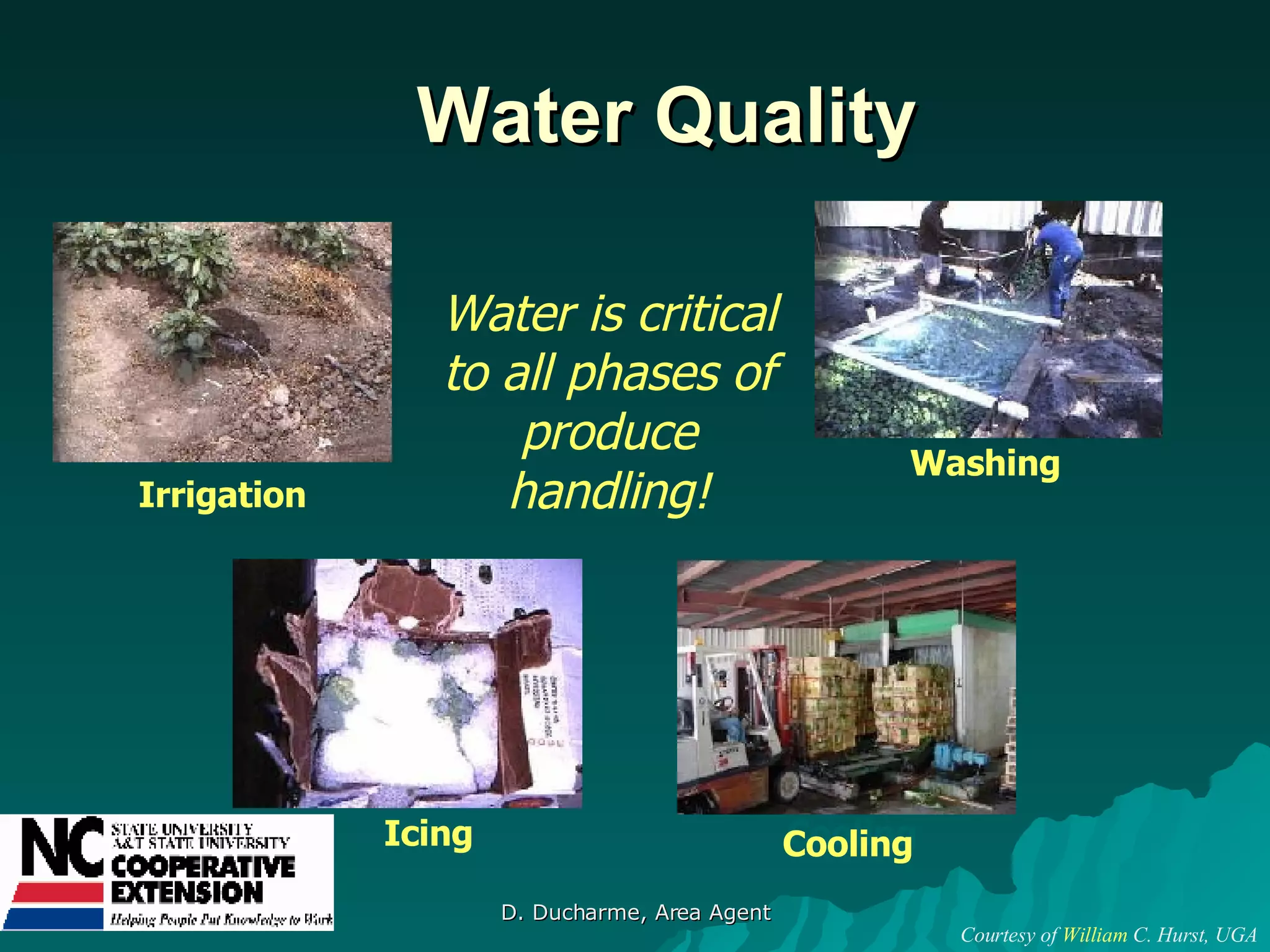

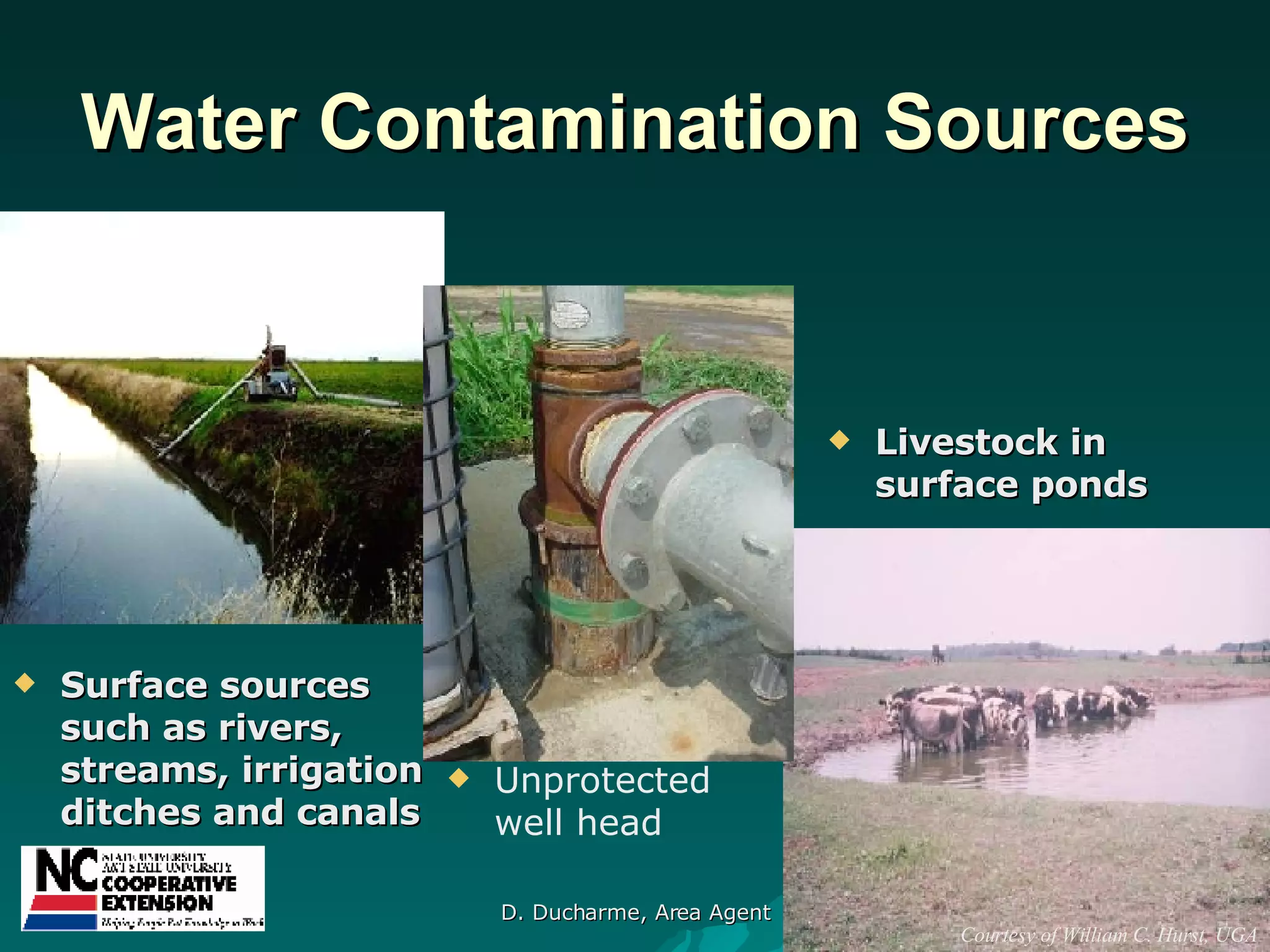

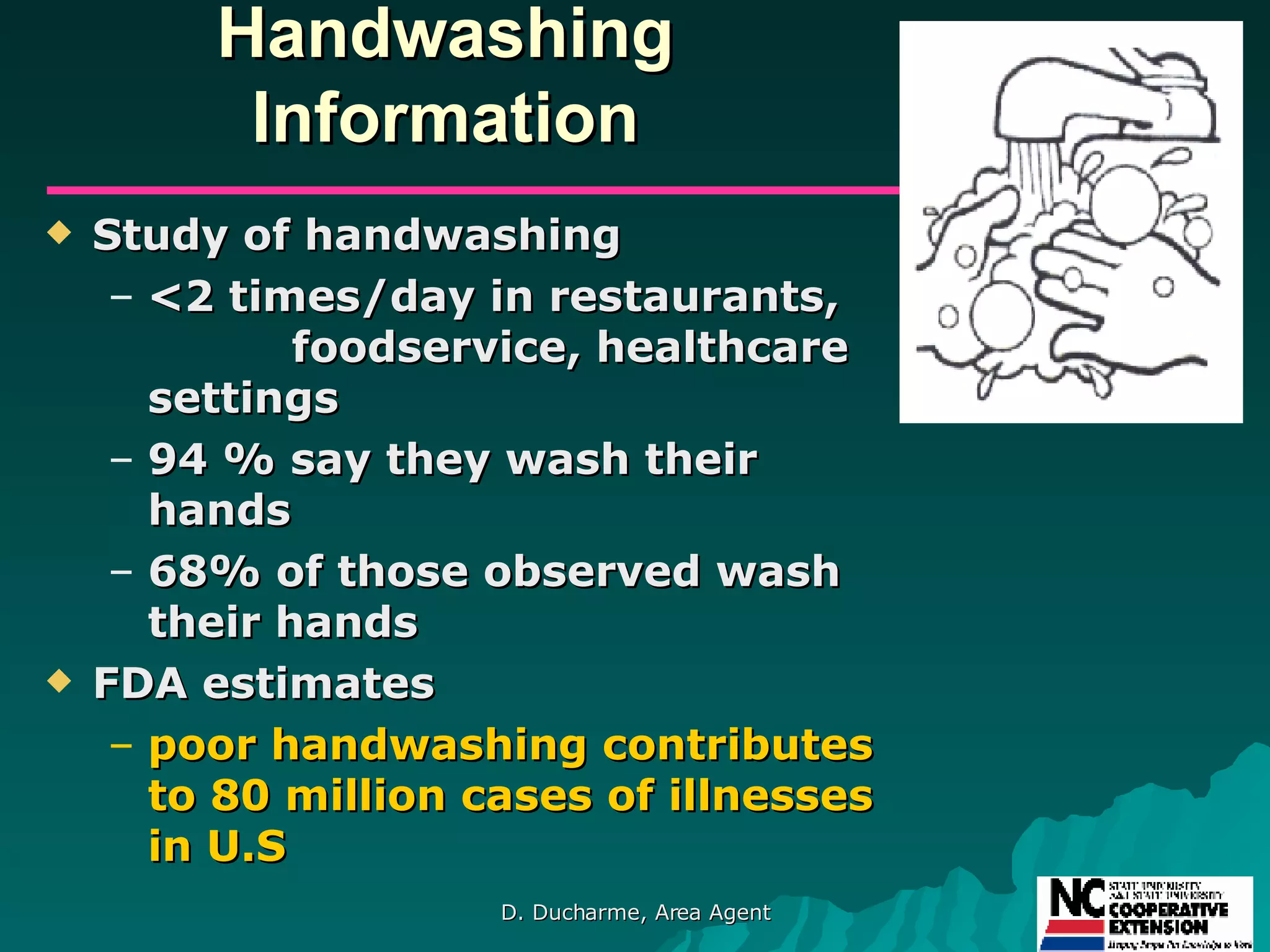

Good Agricultural Practices (GAPs) are a voluntary program that outlines seven practices for fresh produce growers to minimize food safety hazards. The seven practices are: 1) Preventing microbial contamination, 2) Implementing a food safety program, 3) Avoiding contamination from human or animal feces, 4) Ensuring water quality, 5) Properly using animal manures and municipal wastes, 6) Maintaining worker hygiene and sanitation, and 7) Following all applicable laws and regulations. GAPs were created based on Hazard Analysis Critical Control Points (HACCP) principles to address contamination issues from production to distribution of fresh fruits and vegetables.