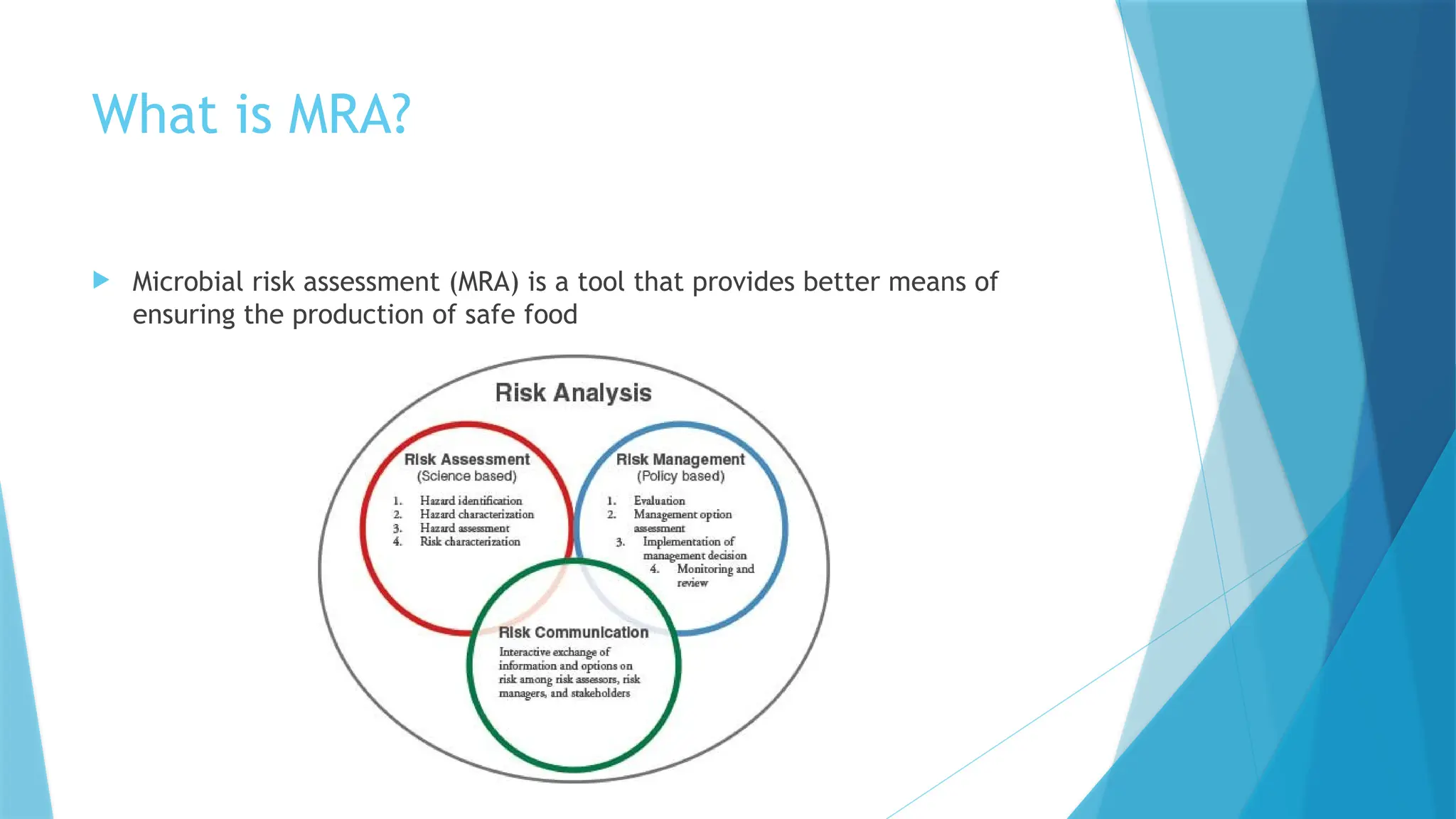

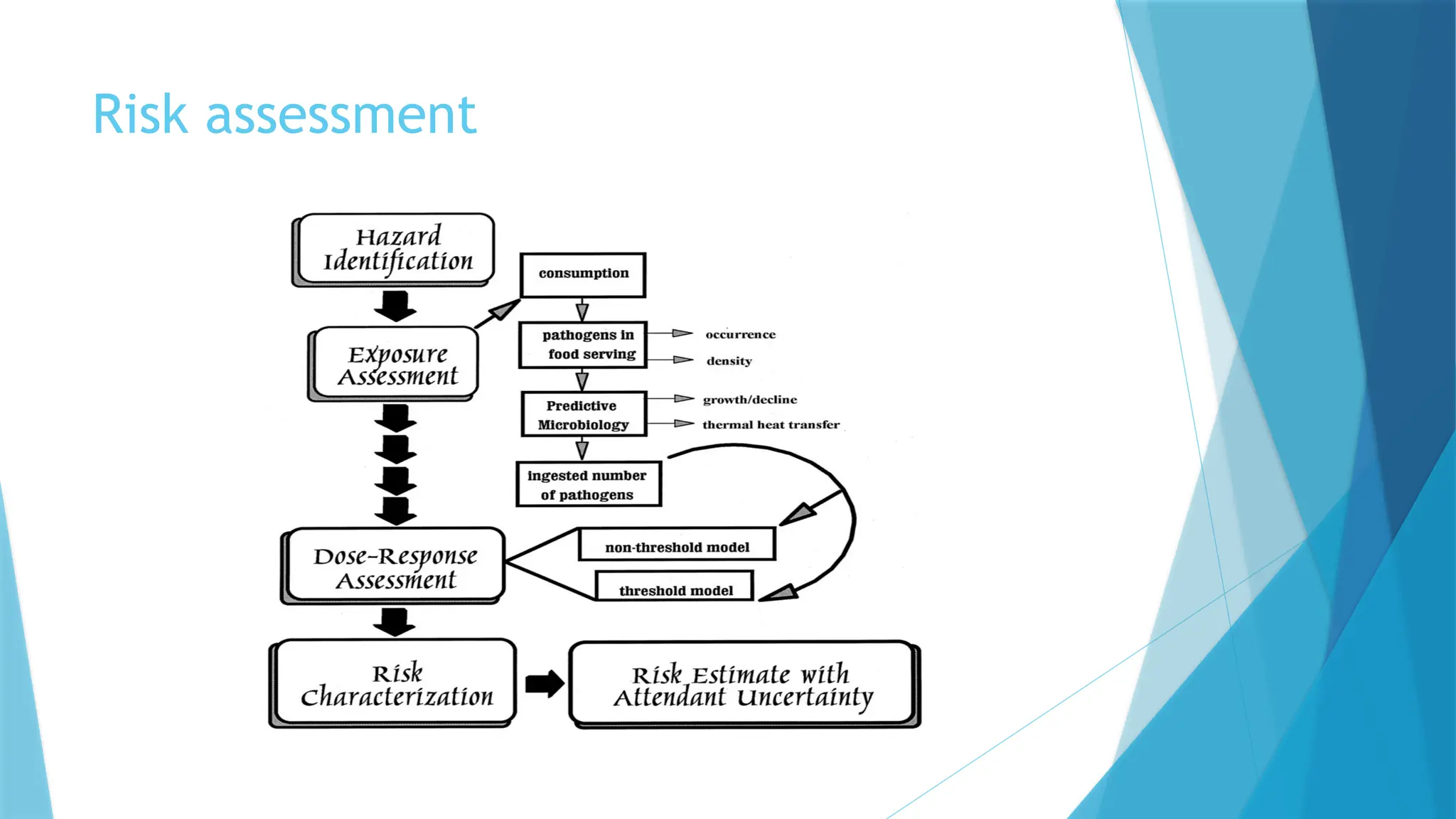

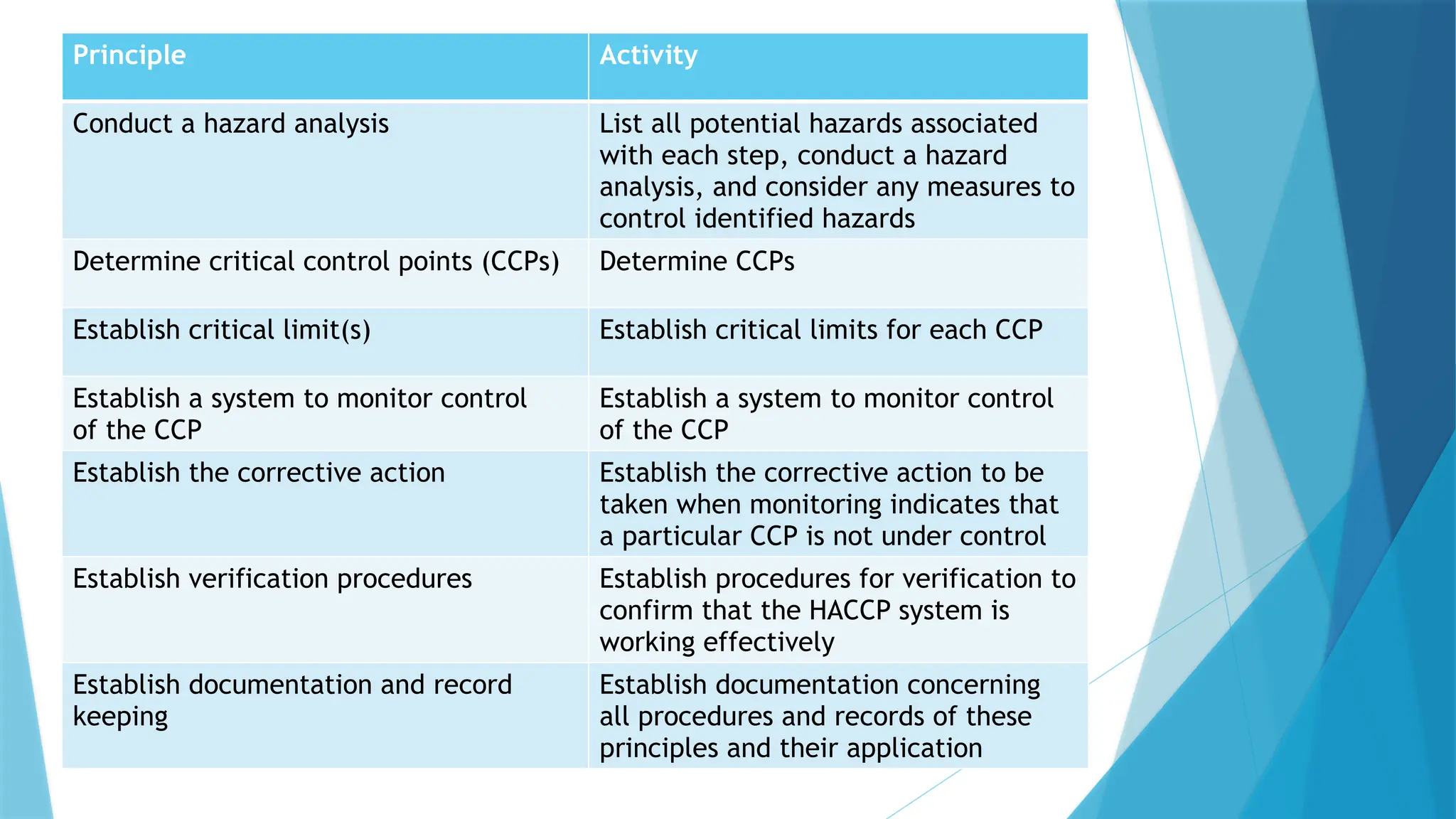

Microbial Risk Assessment (MRA) is a systematic process comprising risk assessment, management, and communication, aimed at ensuring food safety by evaluating potential health impacts from microorganisms. Key components include hazard identification, exposure assessment, hazard characterization, and risk characterization, which together inform effective risk management strategies. International approaches, such as Good Manufacturing Practices (GMP) and the Hazard Analysis Critical Control Point (HACCP) system, play significant roles in minimizing microbial contamination and enhancing food safety standards.