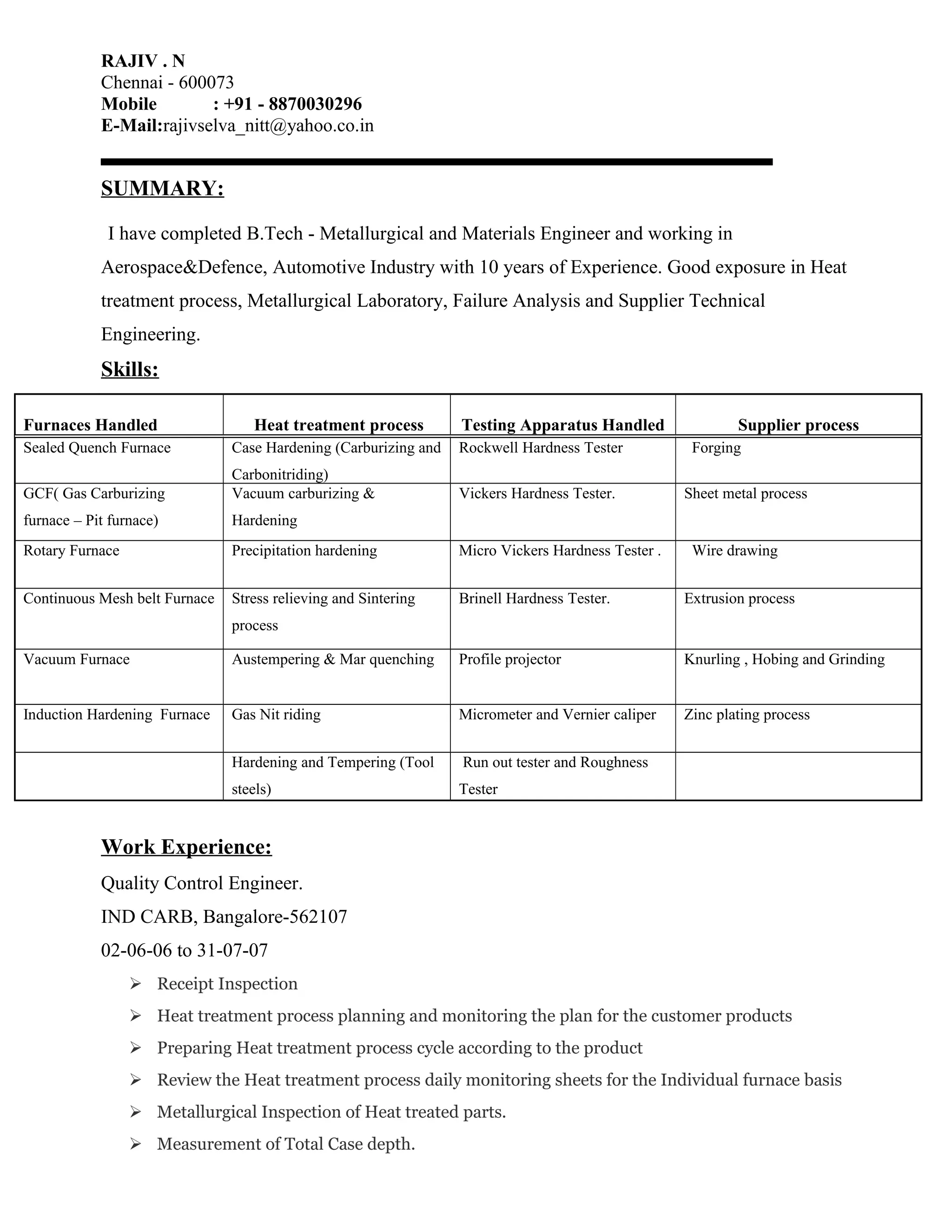

This document contains the resume of Rajiv N. He has over 10 years of experience in metallurgy and heat treatment processes. He has worked in quality control and R&D roles for various automotive and aerospace companies. His skills include experience with furnaces, hardness testing, failure analysis, and developing and auditing heat treatment processes.

![Thanking you

Place : Chennai. Yours Sincerely,

Date : 06.06.2016

[RAJIV. N]](https://image.slidesharecdn.com/a8cd51b4-ff17-4c4b-bc89-3c74bd6642a4-160616064037/85/Resume-Metallurgy-latest-4-320.jpg)