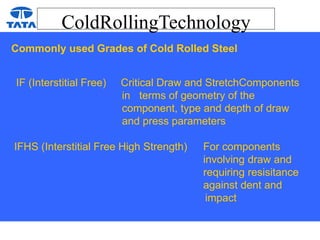

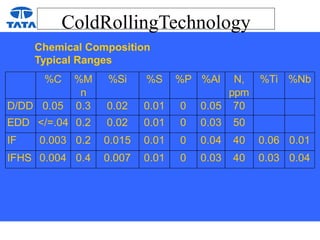

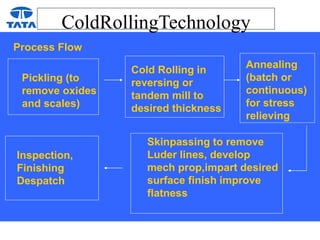

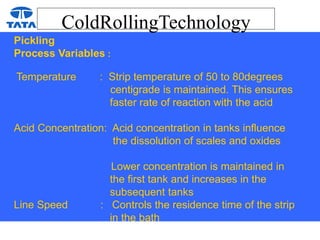

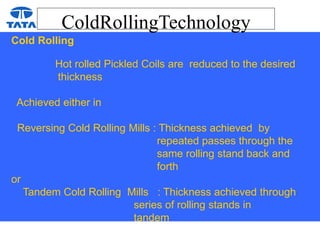

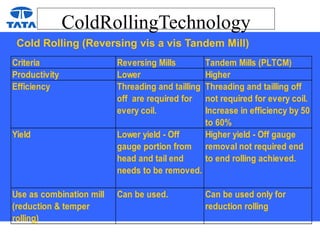

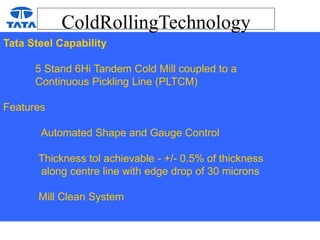

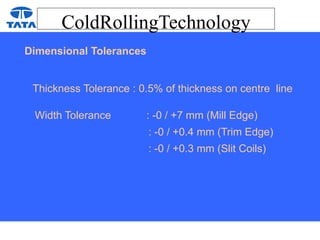

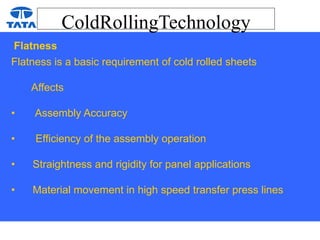

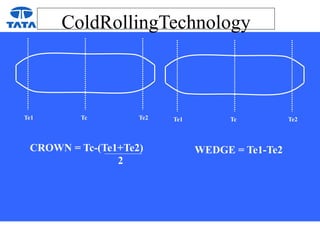

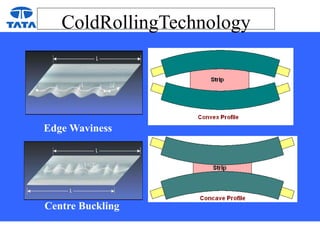

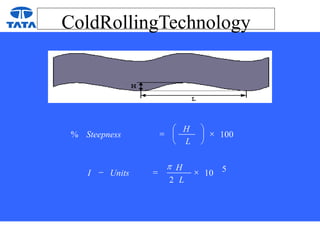

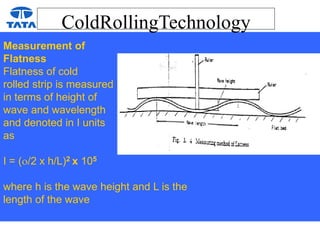

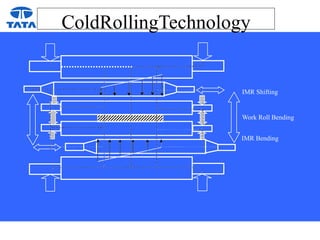

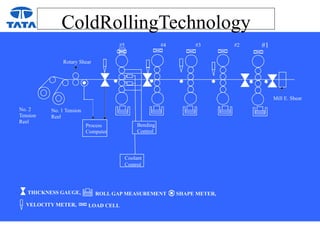

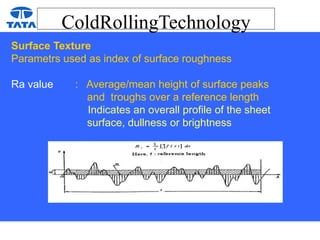

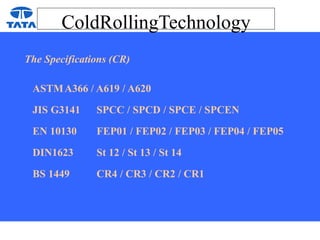

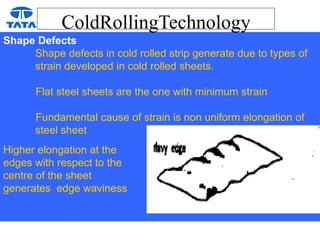

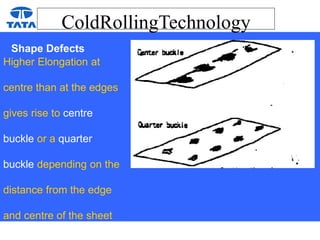

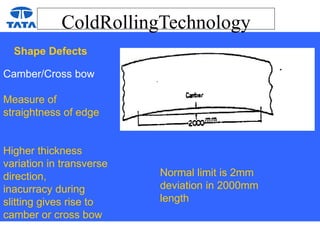

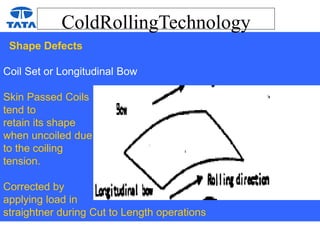

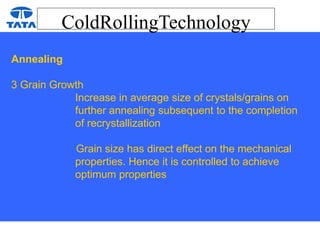

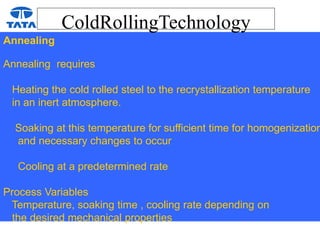

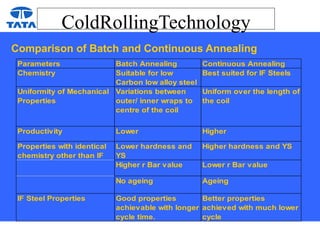

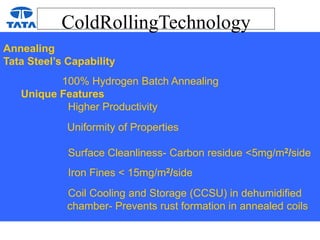

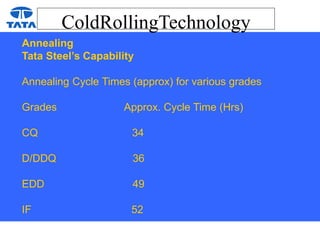

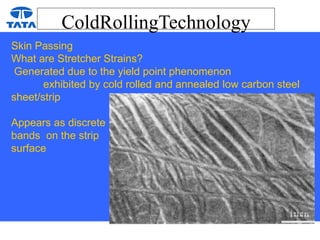

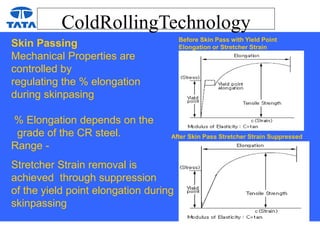

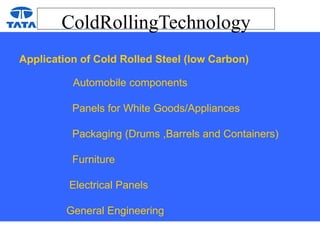

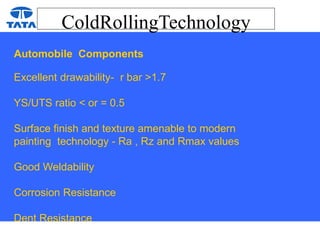

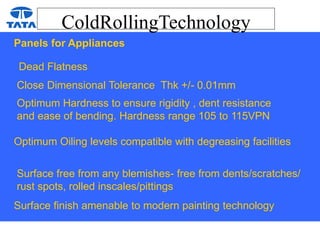

This document provides an overview of cold rolling technology. It discusses the different types of cold rolling mills and their components. It describes the cold rolling process including pickling, cold rolling, annealing and skin passing. It explains process parameters like thickness and width tolerances, flatness control, and defects in cold rolled steel. It also provides details about Tata Steel's cold rolling capabilities including its pickling line, tandem cold mill, annealing and skin passing facilities.