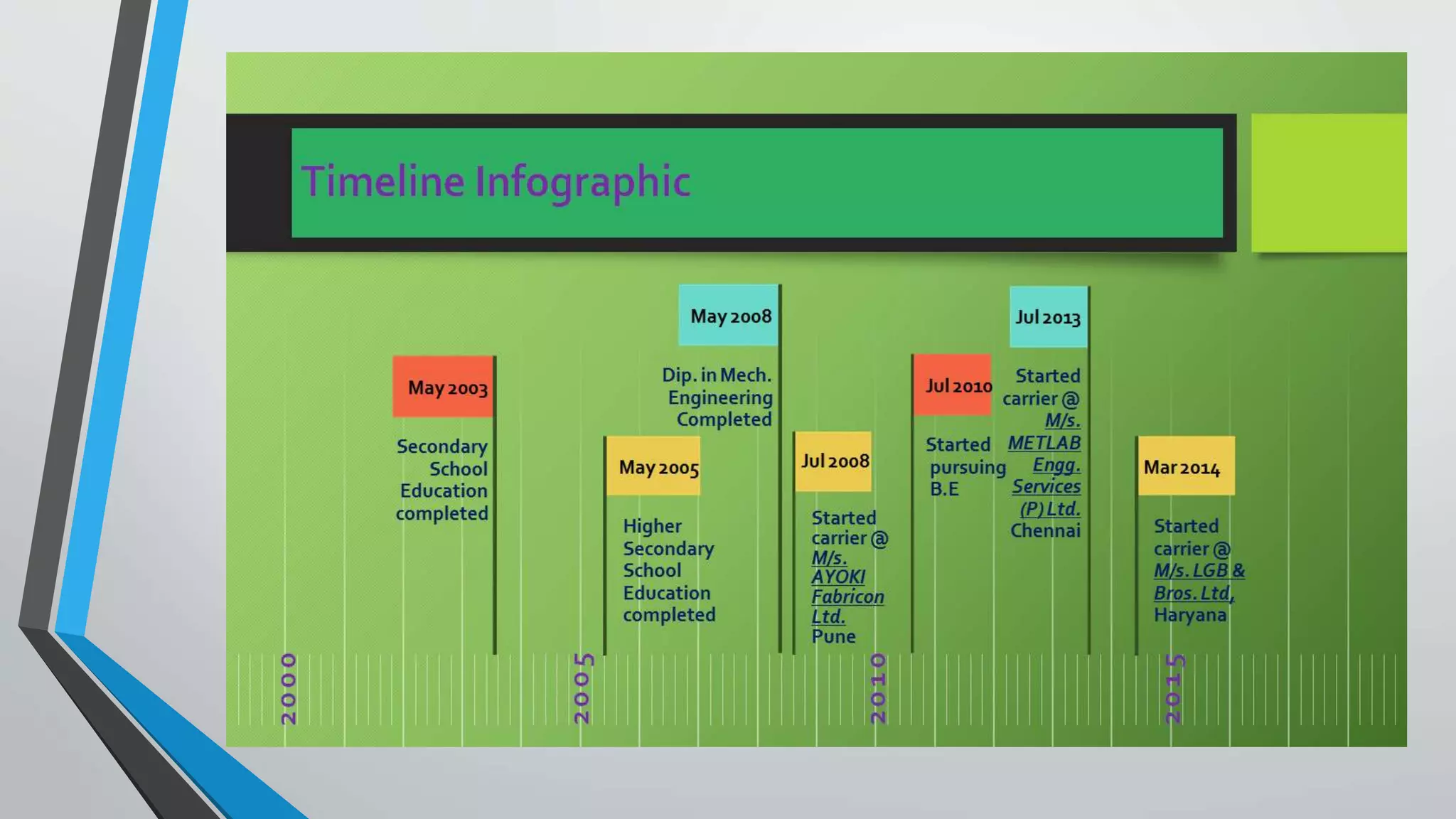

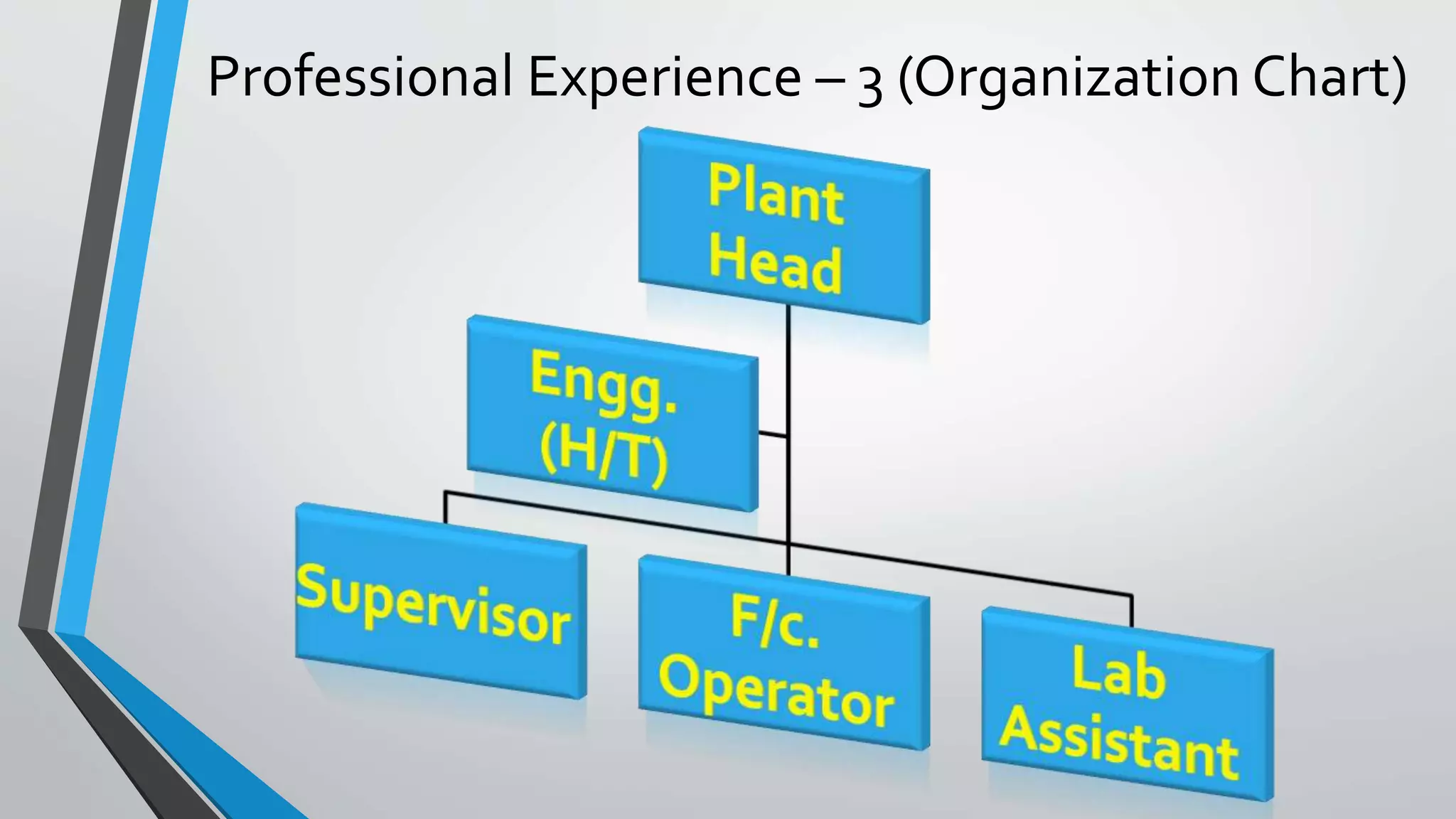

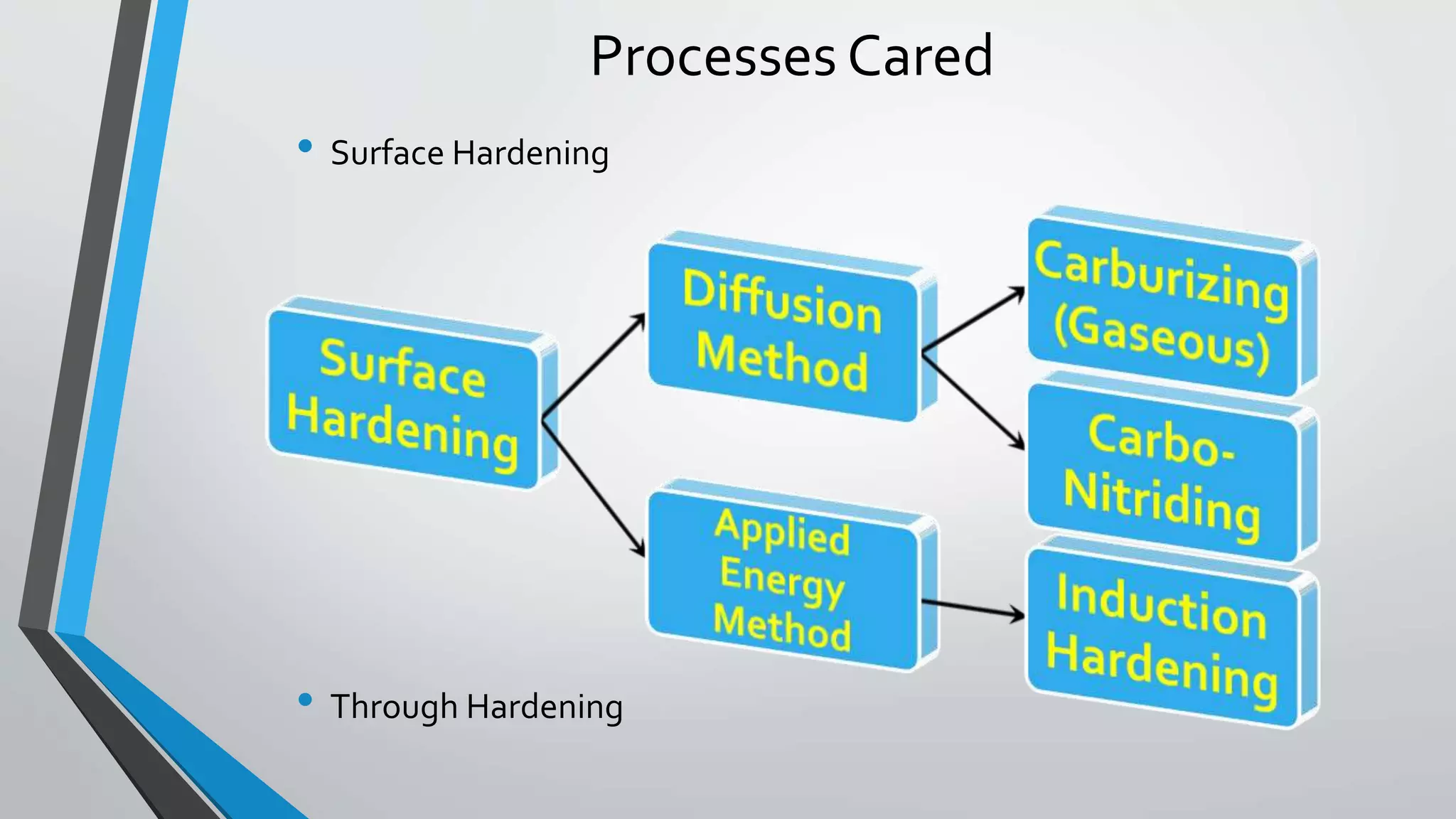

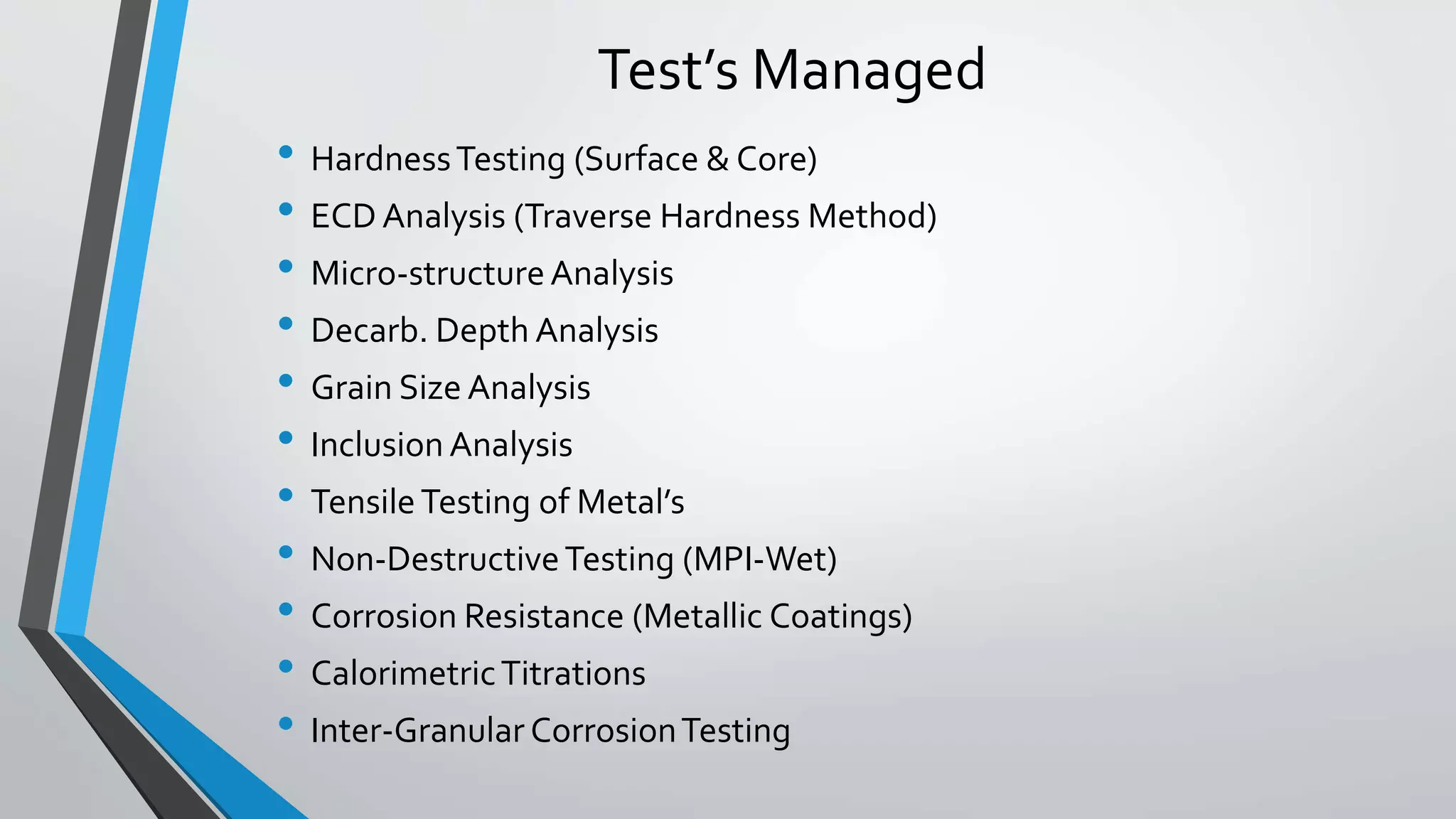

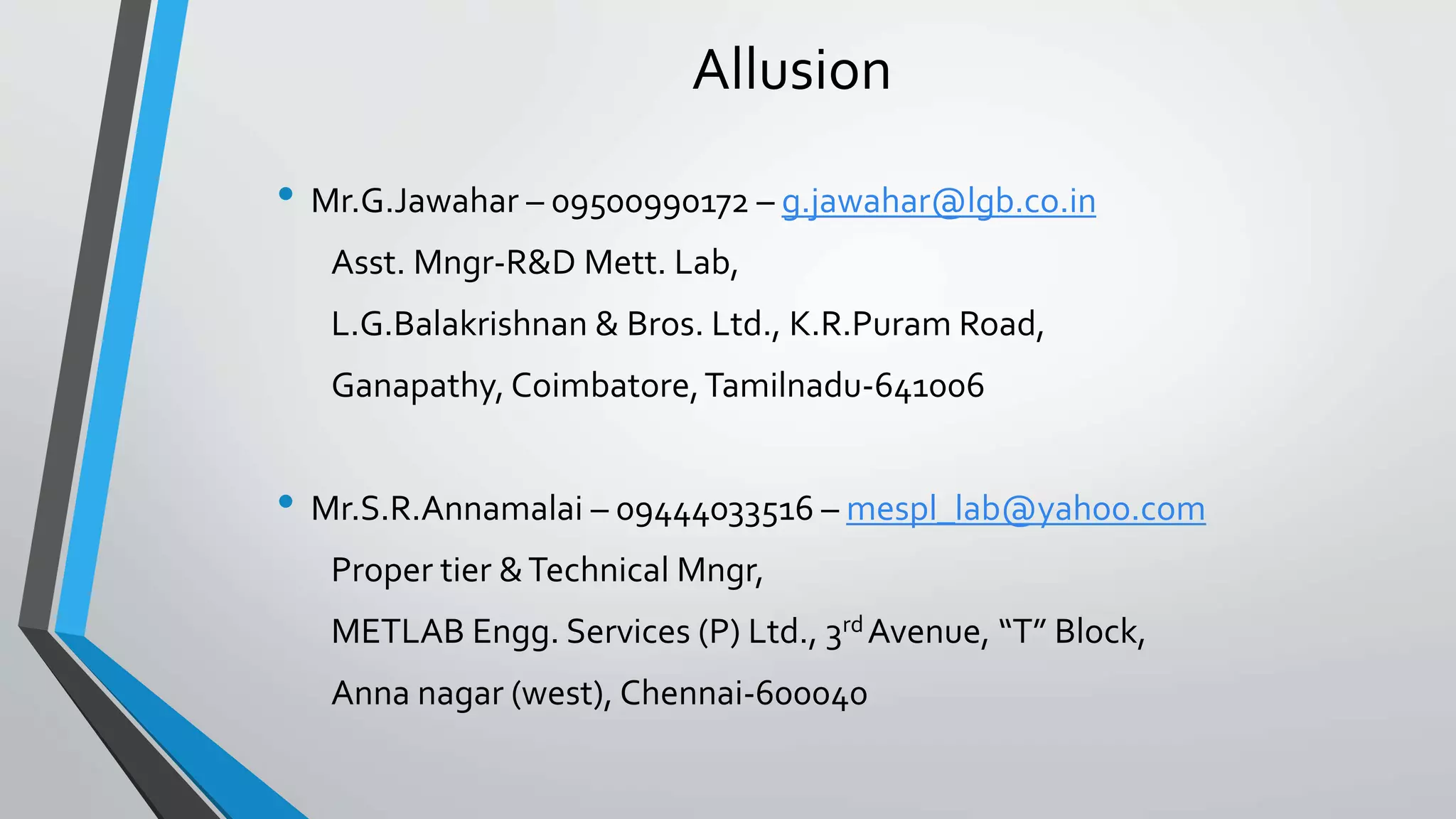

This document contains the resume of PRABAKARAN.K. It summarizes his educational qualifications including a B.E in Materials Science & Engineering and diploma in Mechanical Engineering. It also outlines his professional experience in three roles - as a Junior Engineer in fabrication at Ayoki Fabricon Pvt Ltd, as a Metallurgist at METLAB Engineering Services, and currently as an Engineering - Heat Treatment professional at L.G.Balakrishnan & Bros Ltd. It provides details of his responsibilities, processes managed, equipment experience, and references.