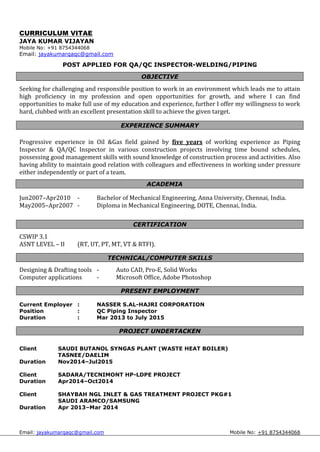

Jayakumar Vijayan is seeking a position as a QA/QC Inspector for welding and piping. He has over 5 years of experience in piping inspection and QA/QC for oil and gas projects. He holds a Bachelor's degree in Mechanical Engineering as well as certifications in welding inspection. His responsibilities have included verifying drawings, inspecting materials and welds, coordinating testing and inspections, and ensuring quality standards are met.