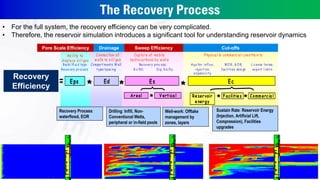

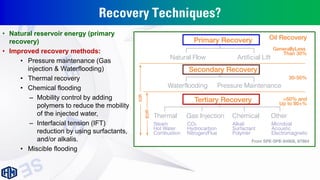

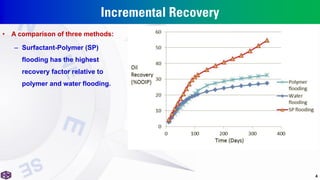

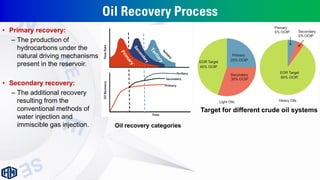

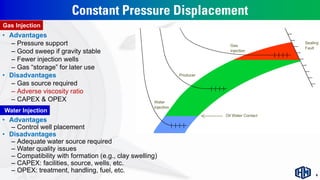

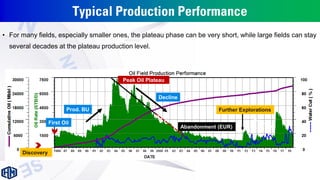

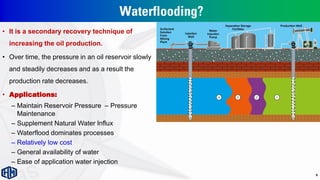

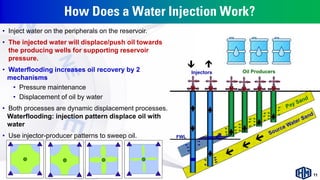

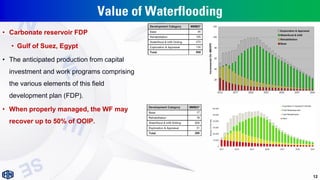

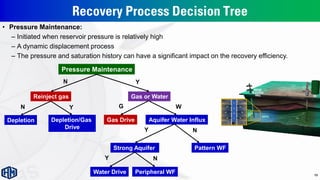

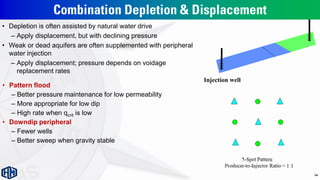

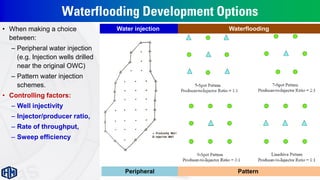

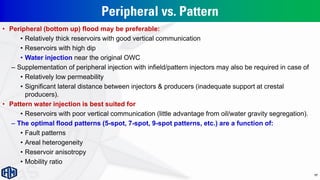

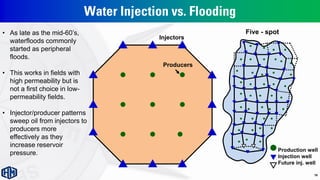

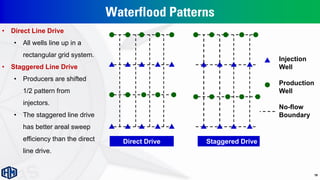

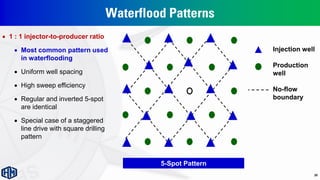

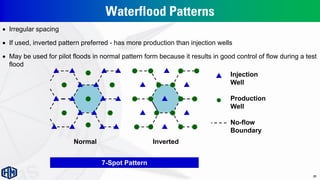

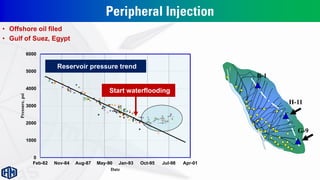

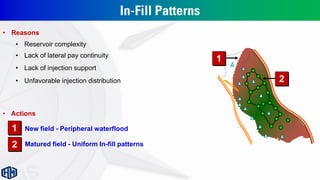

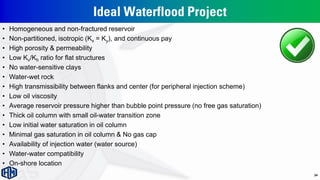

The document discusses various oil recovery techniques, focusing on waterflooding. It summarizes that waterflooding involves injecting water into reservoirs to increase pressure and displace oil towards production wells, potentially recovering up to 50% of oil originally in place. The document discusses factors in choosing between peripheral and pattern water injection schemes and describes various pattern designs, noting 5-spot and 7-spot patterns are commonly used.