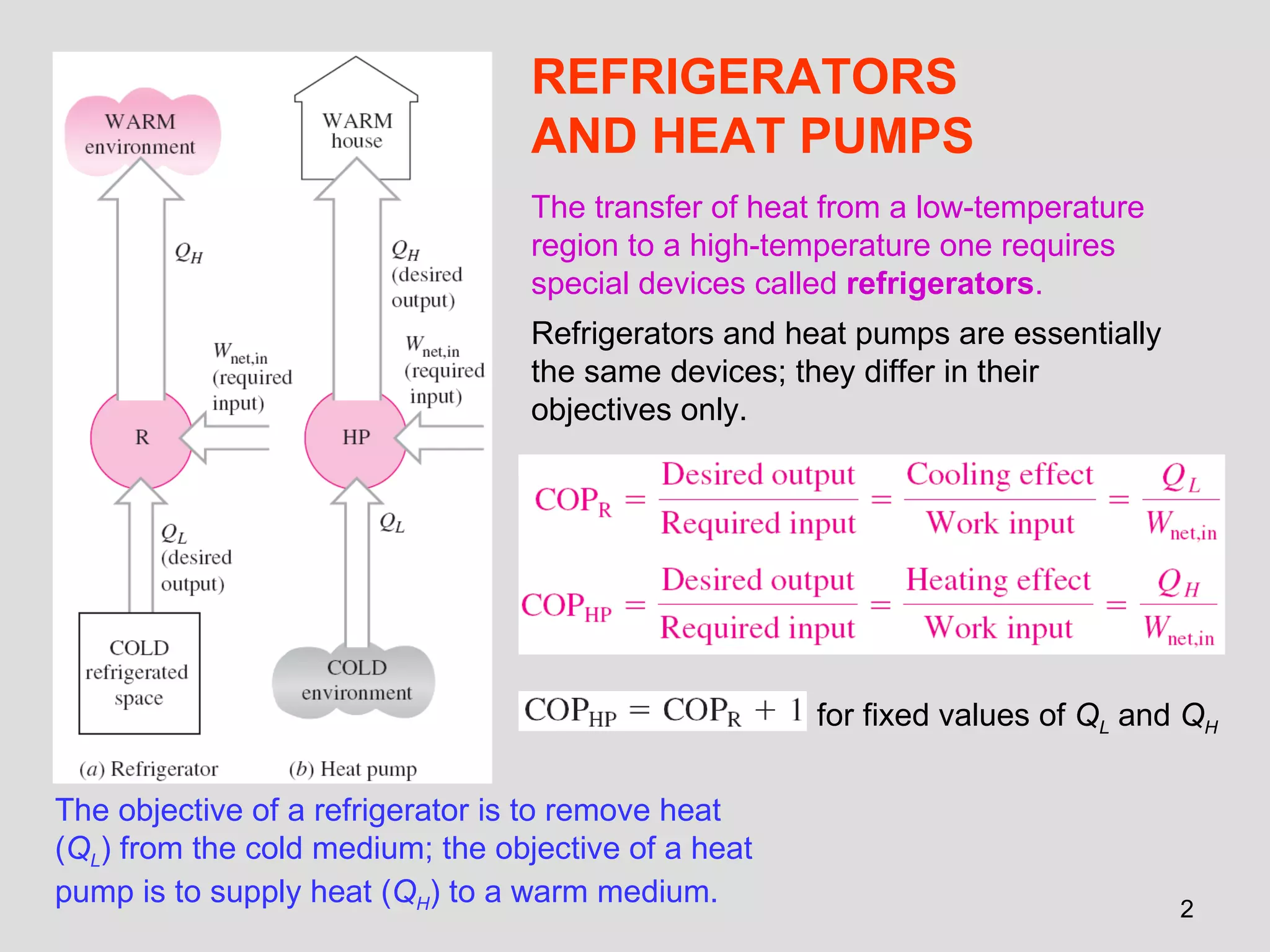

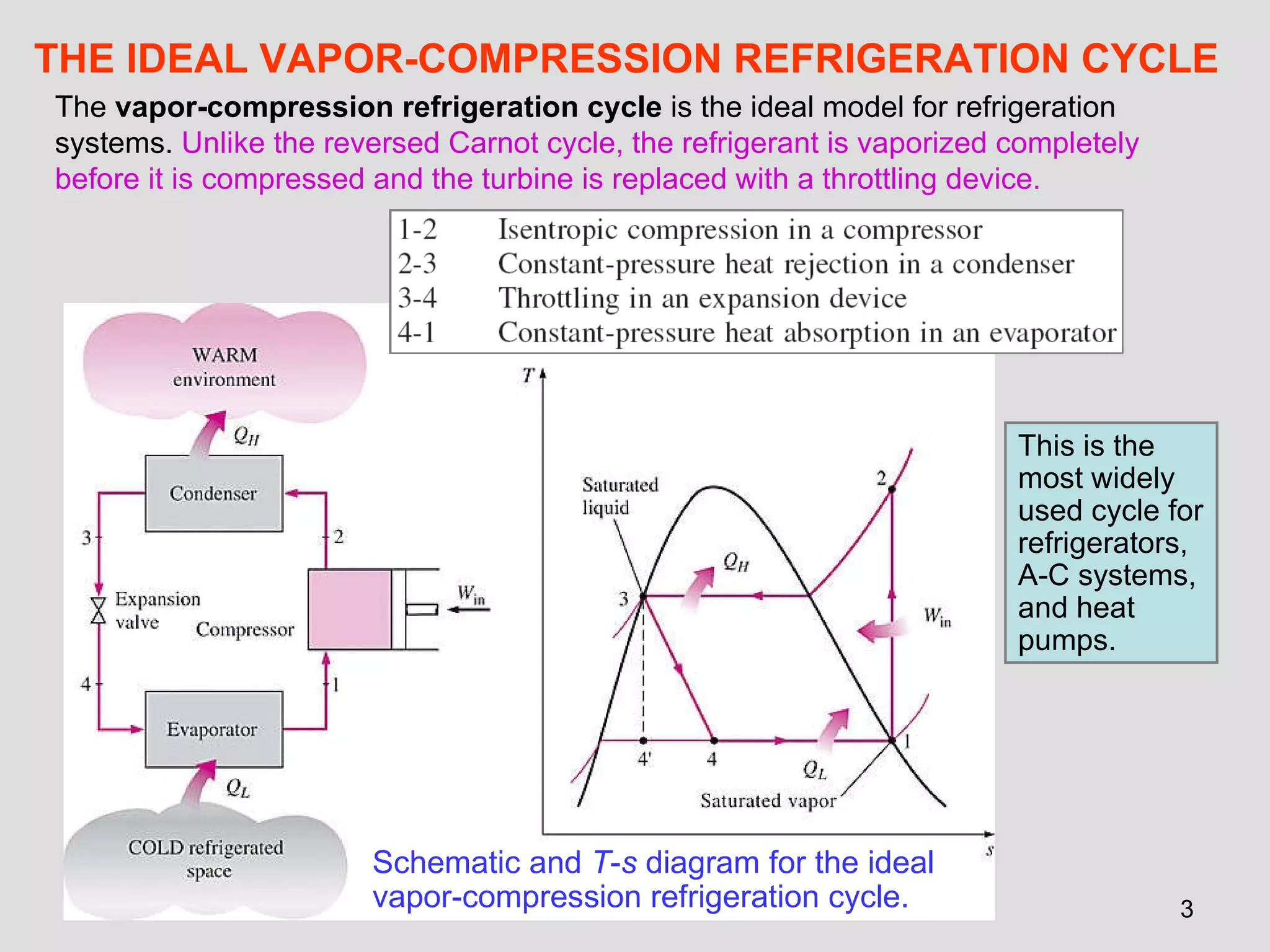

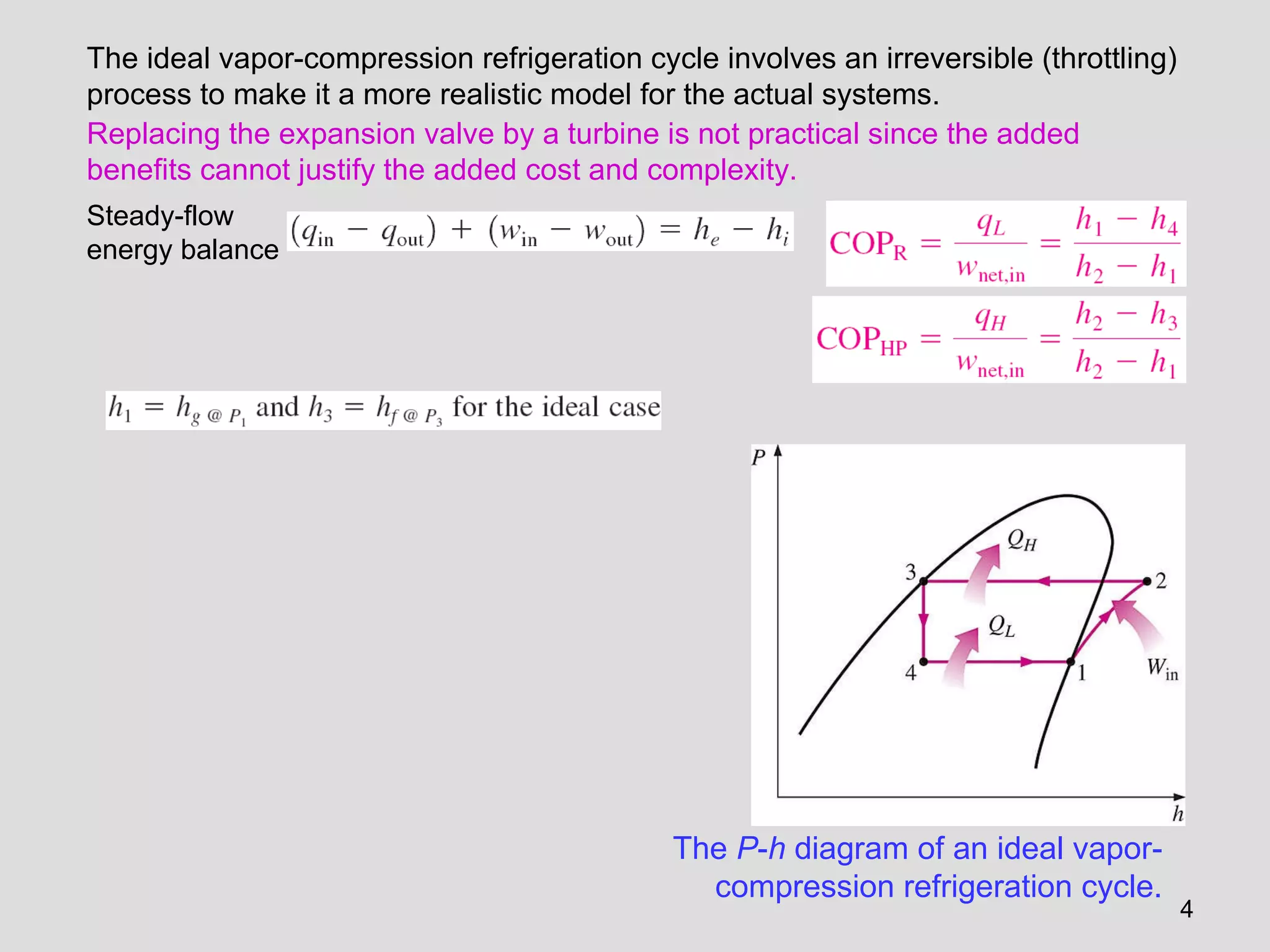

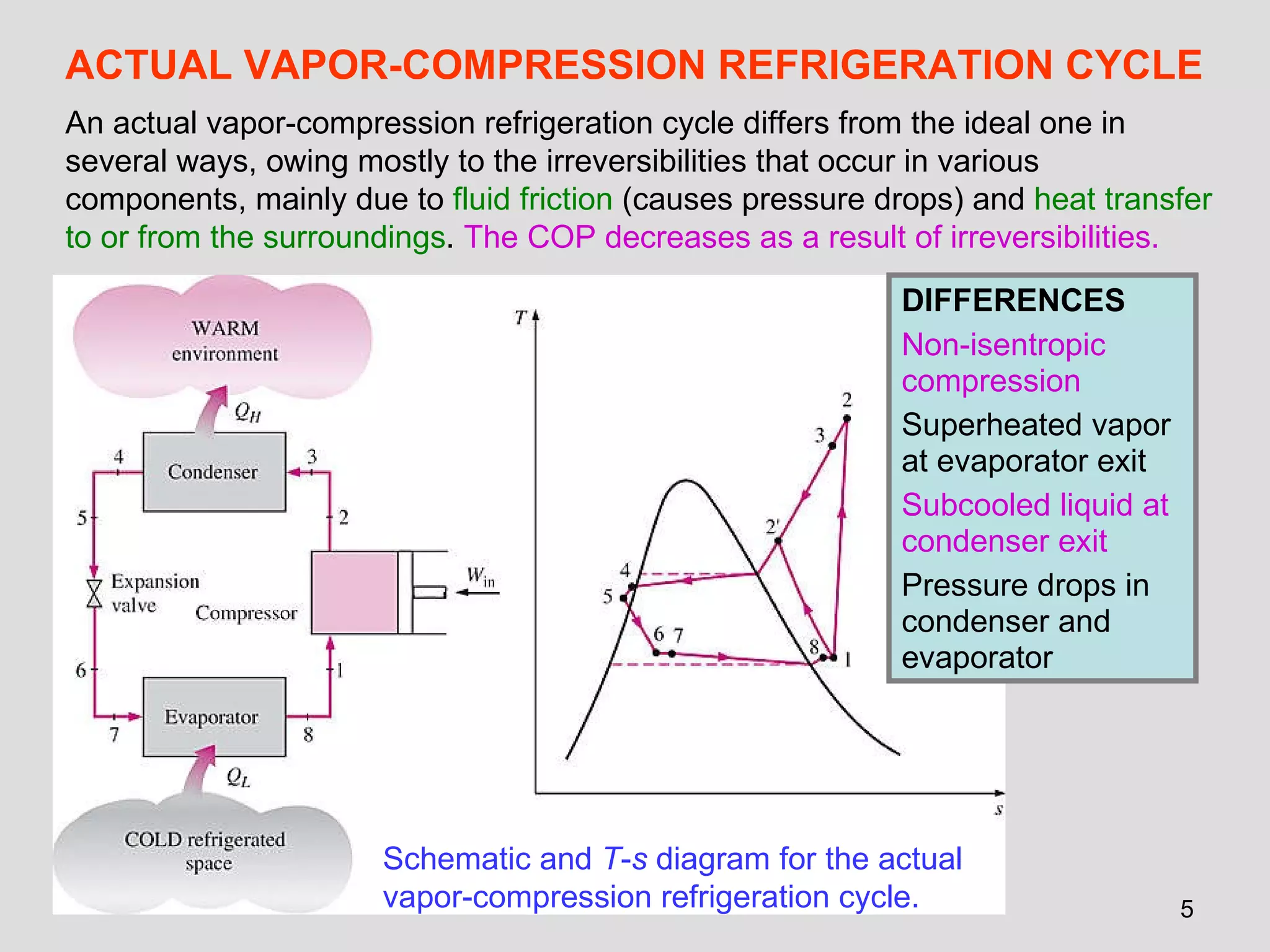

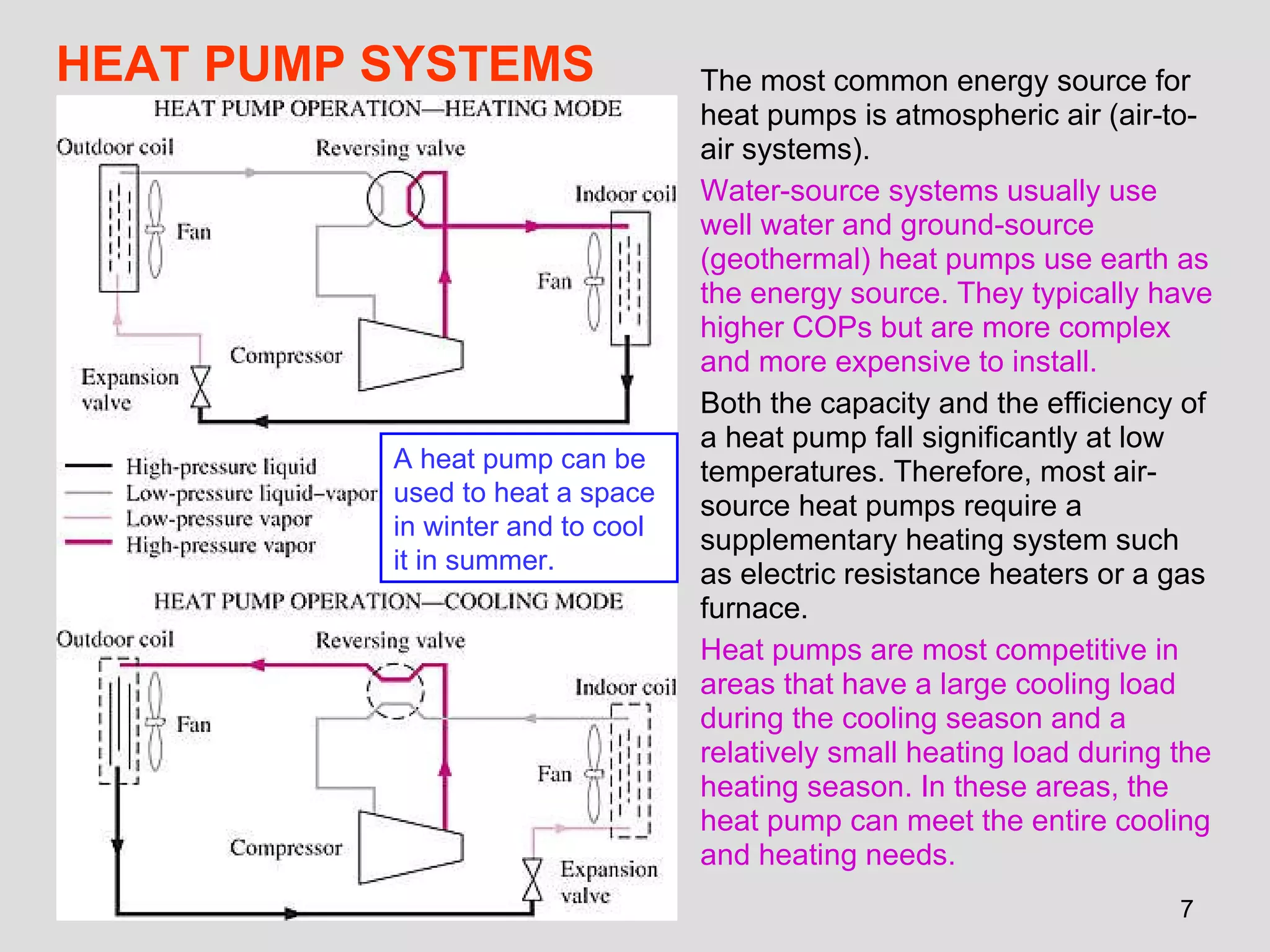

The document discusses the ideal and actual vapor-compression refrigeration cycles. The ideal cycle involves reversible processes while the actual cycle accounts for irreversibilities in components. Several refrigerants are discussed for use in refrigeration systems, with factors like ozone depletion and global warming potential considered in selection. Heat pumps are also covered, with air, water, and ground-source systems compared for heating and cooling applications.