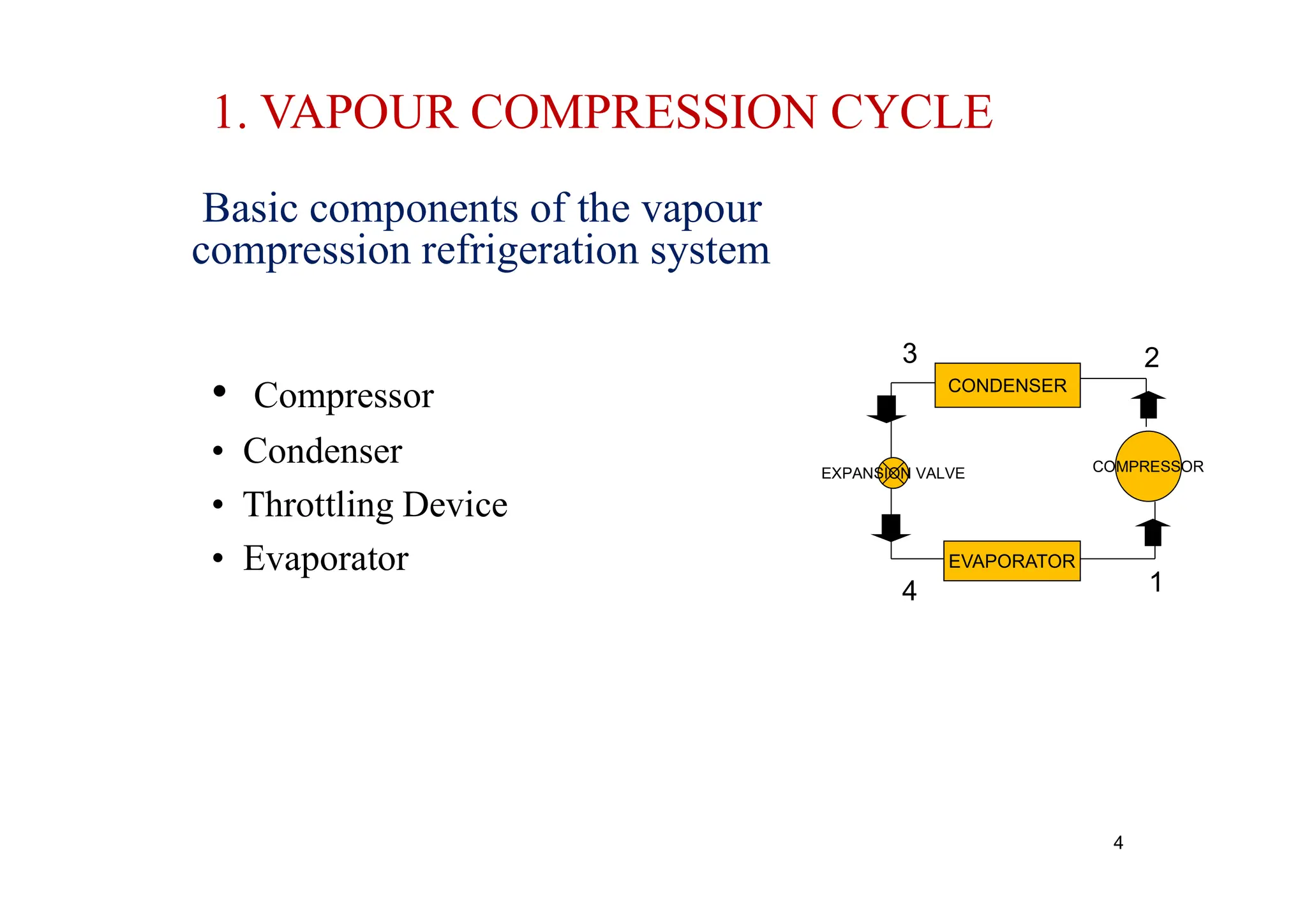

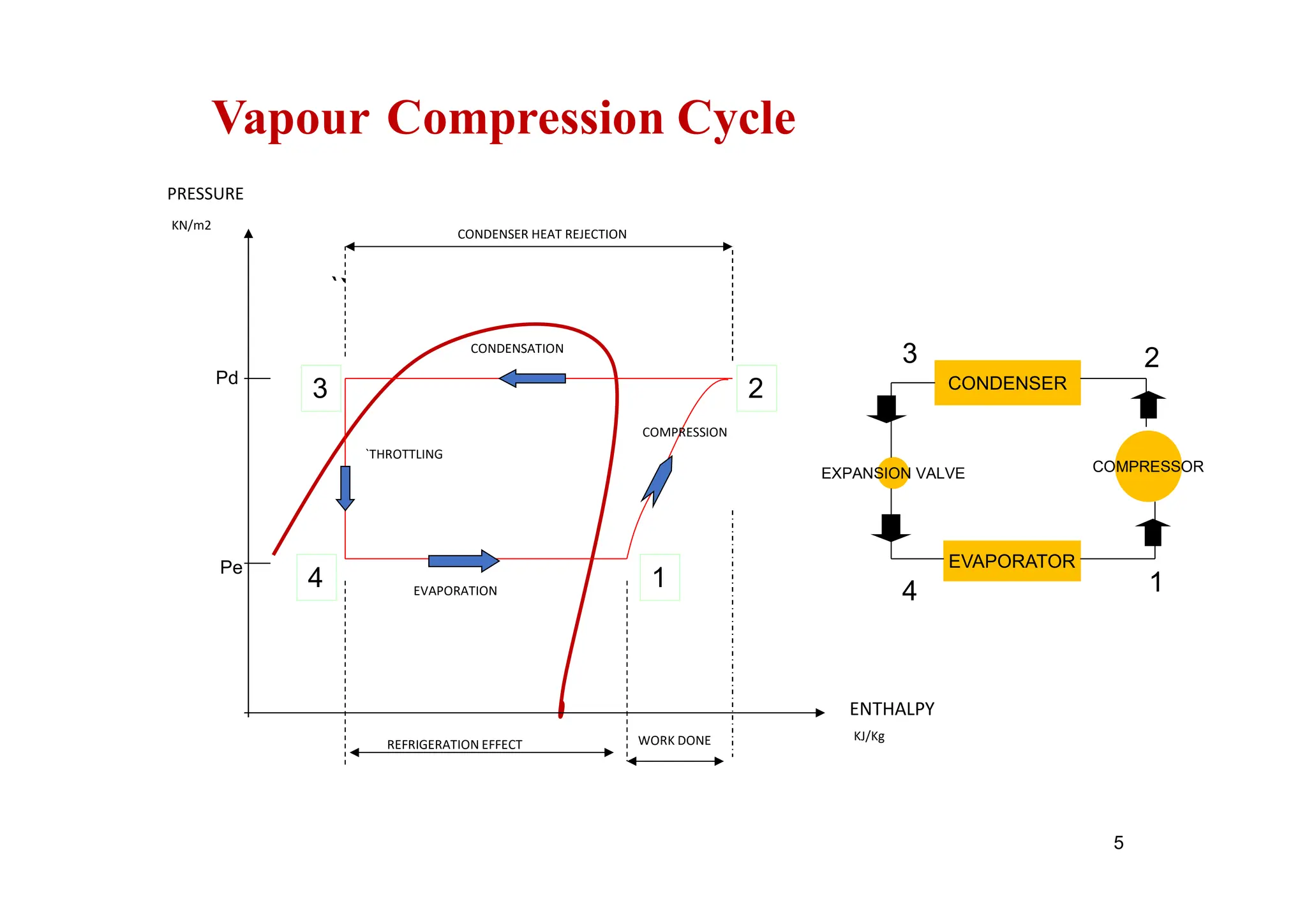

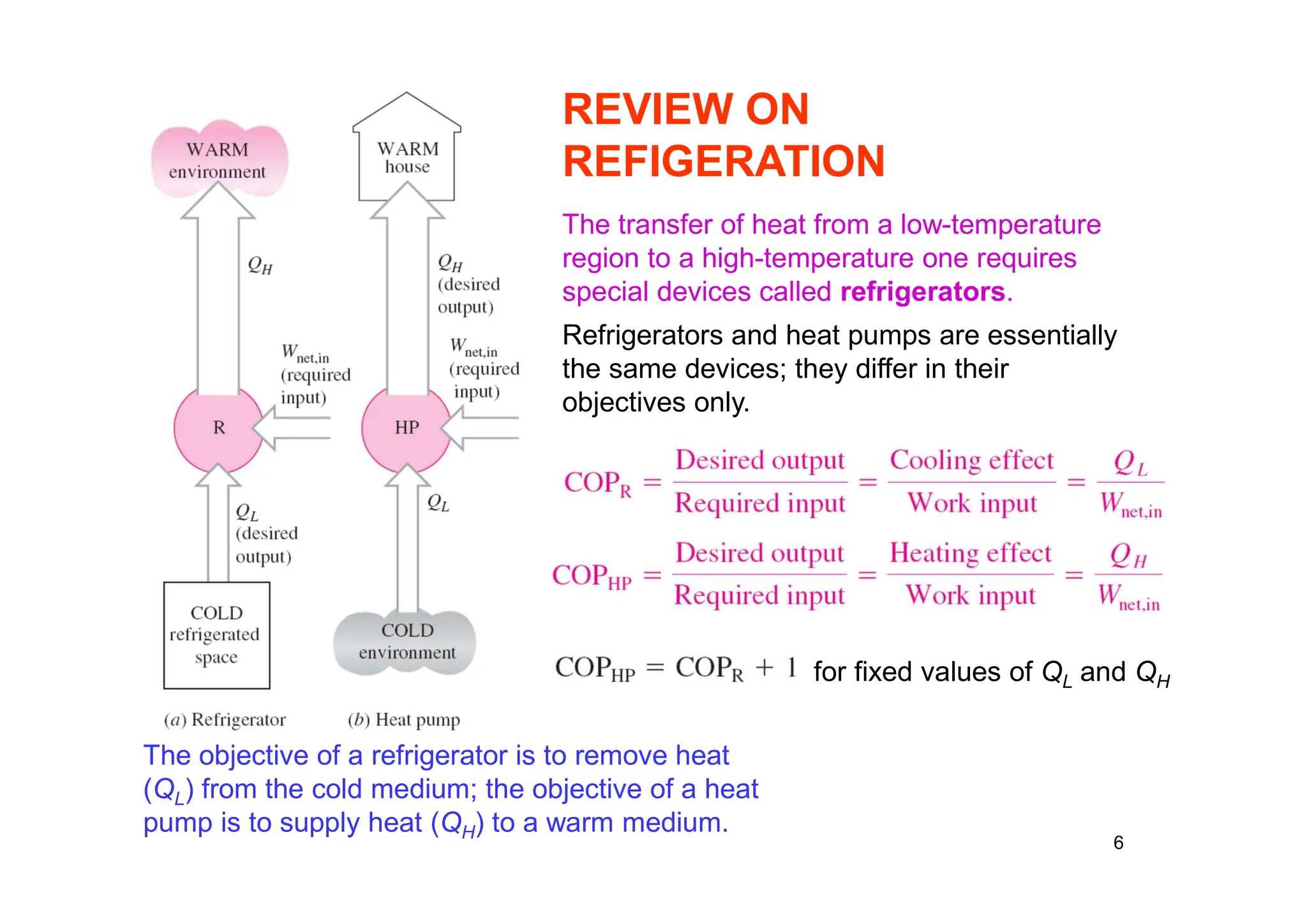

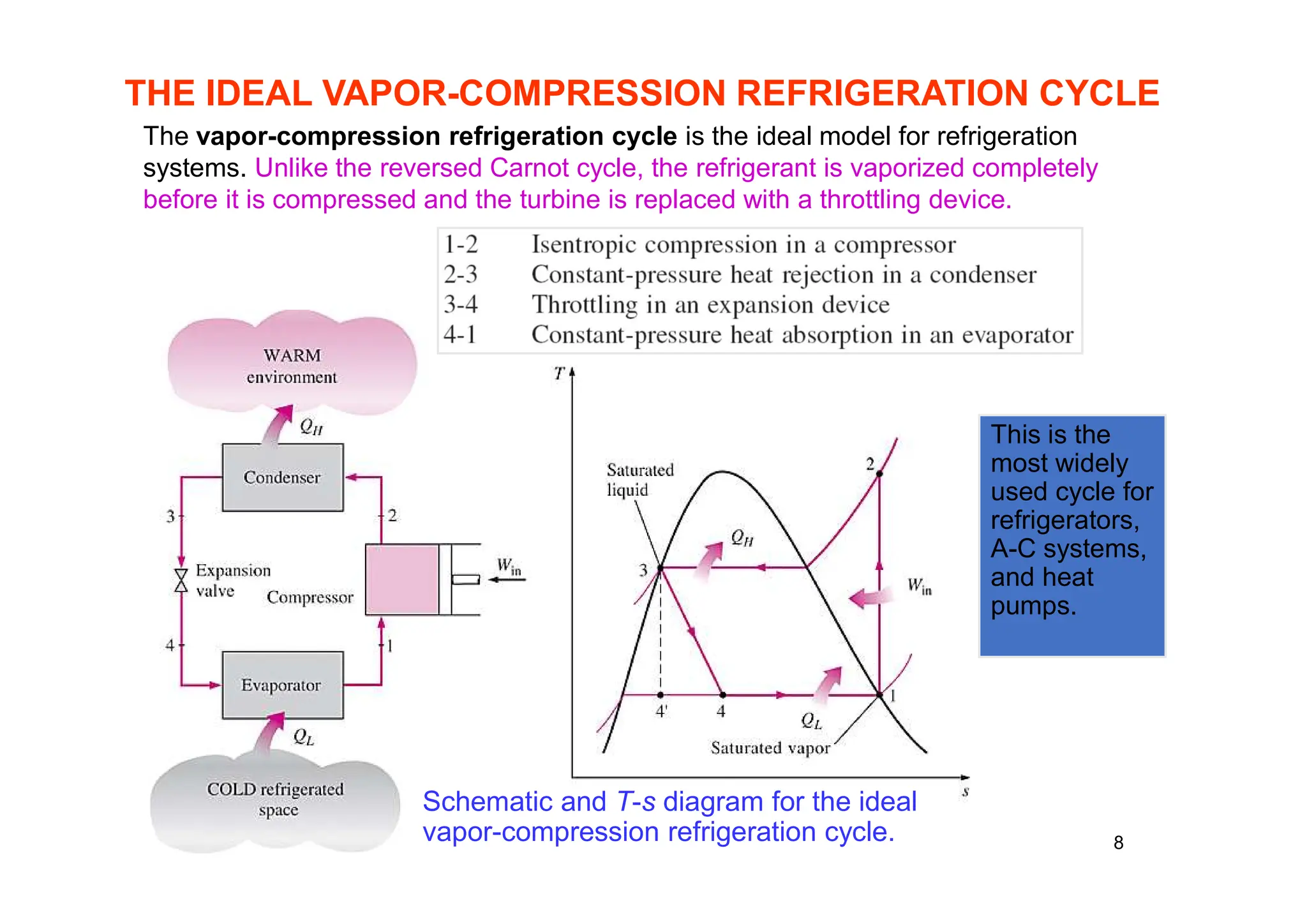

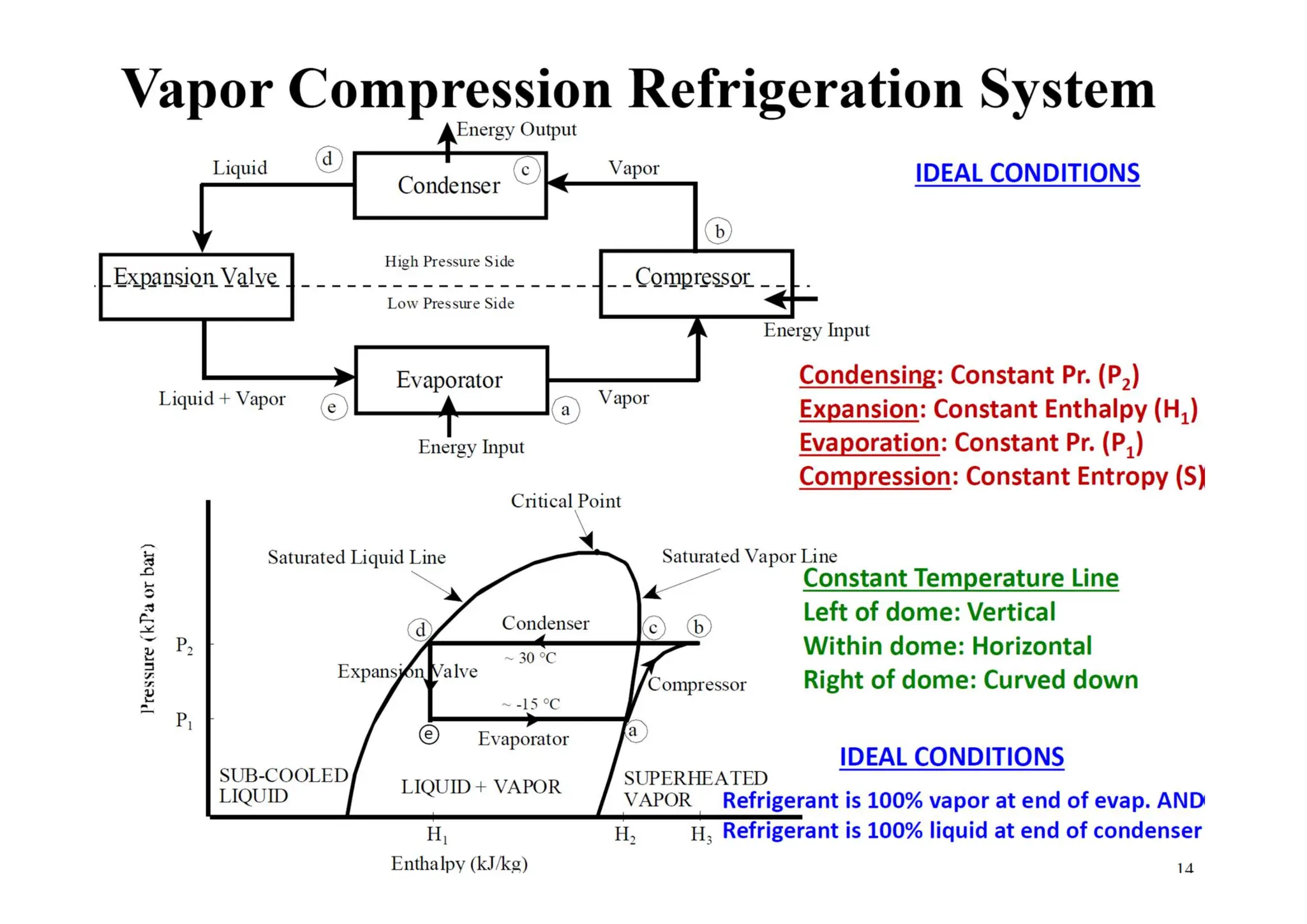

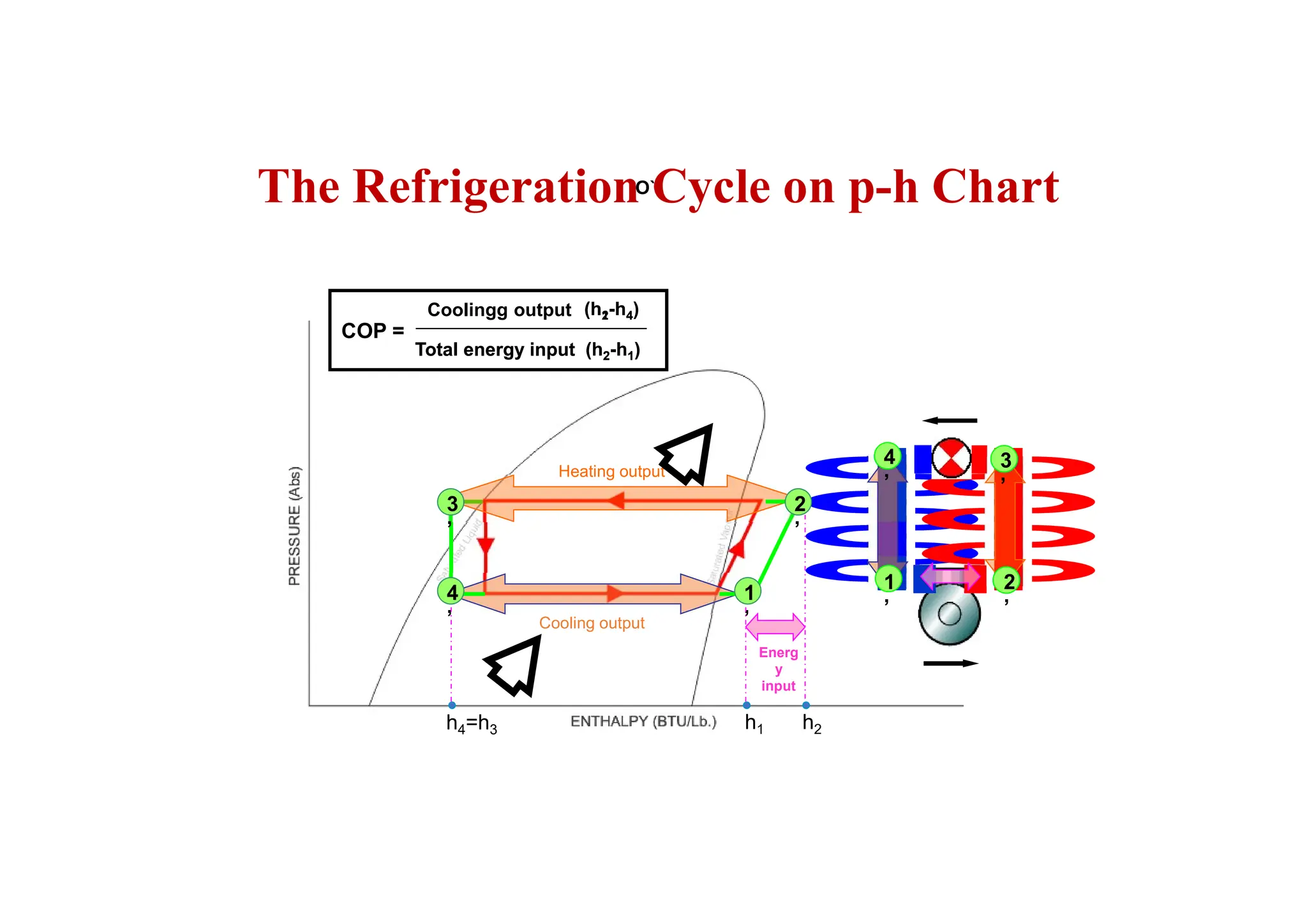

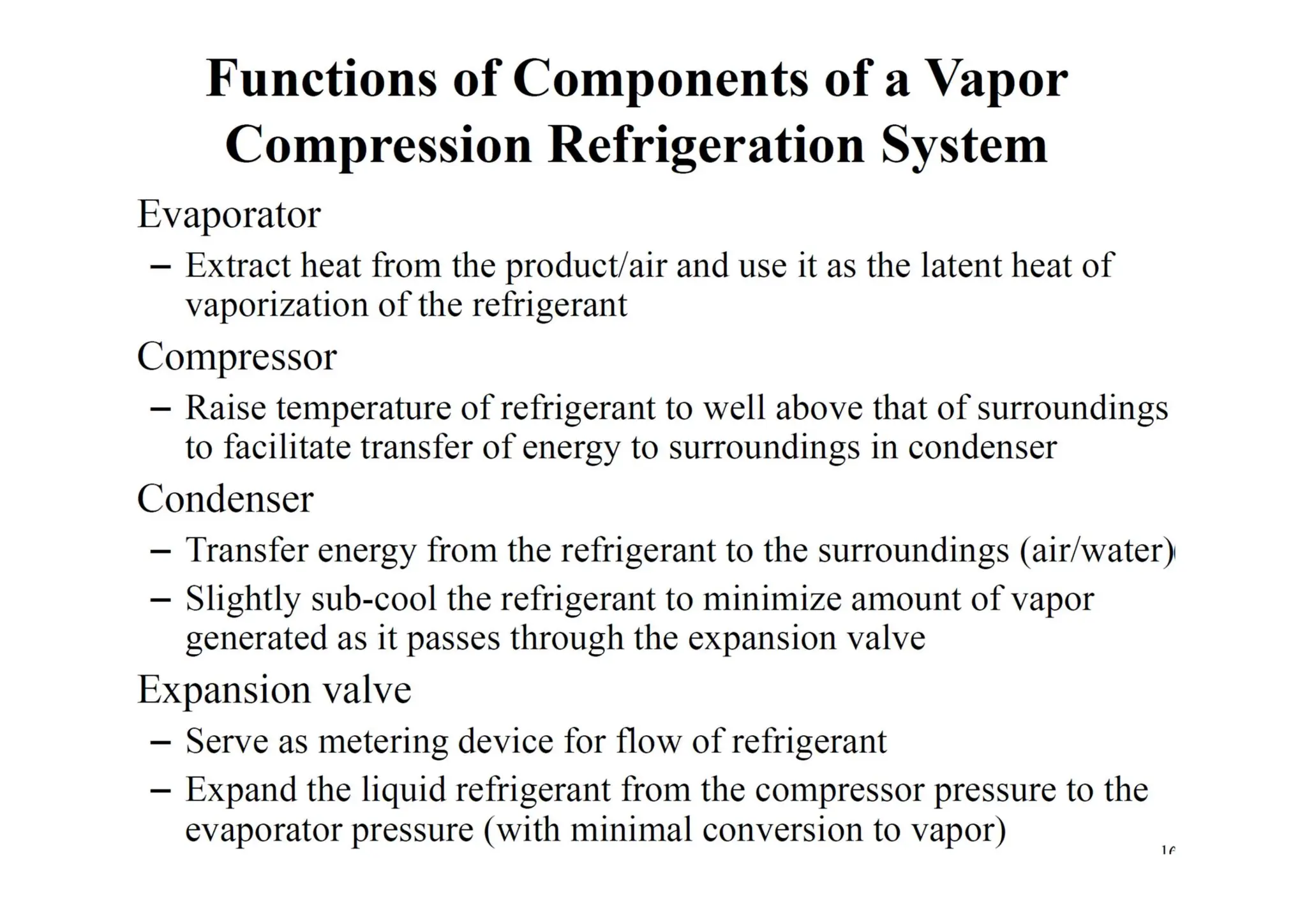

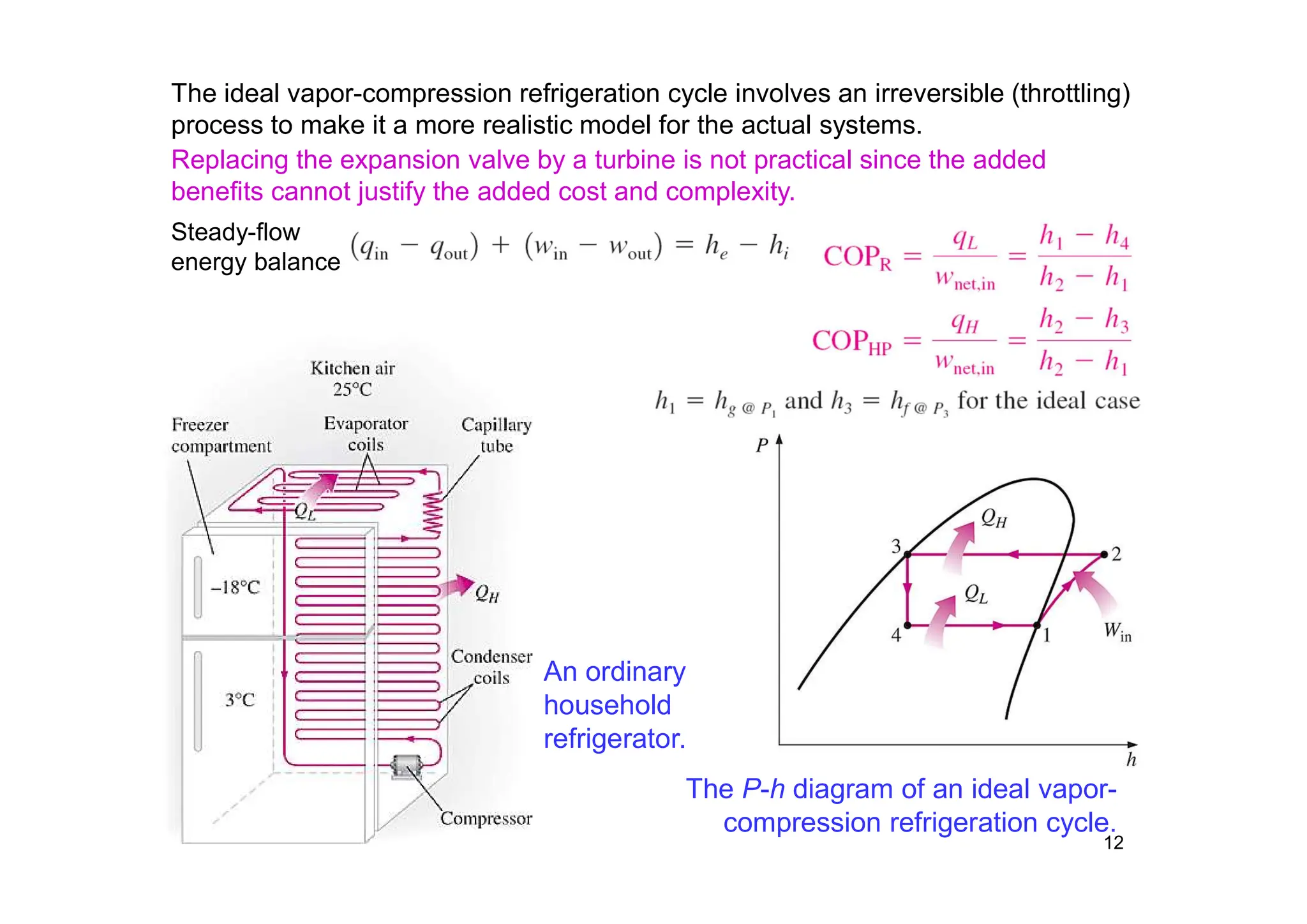

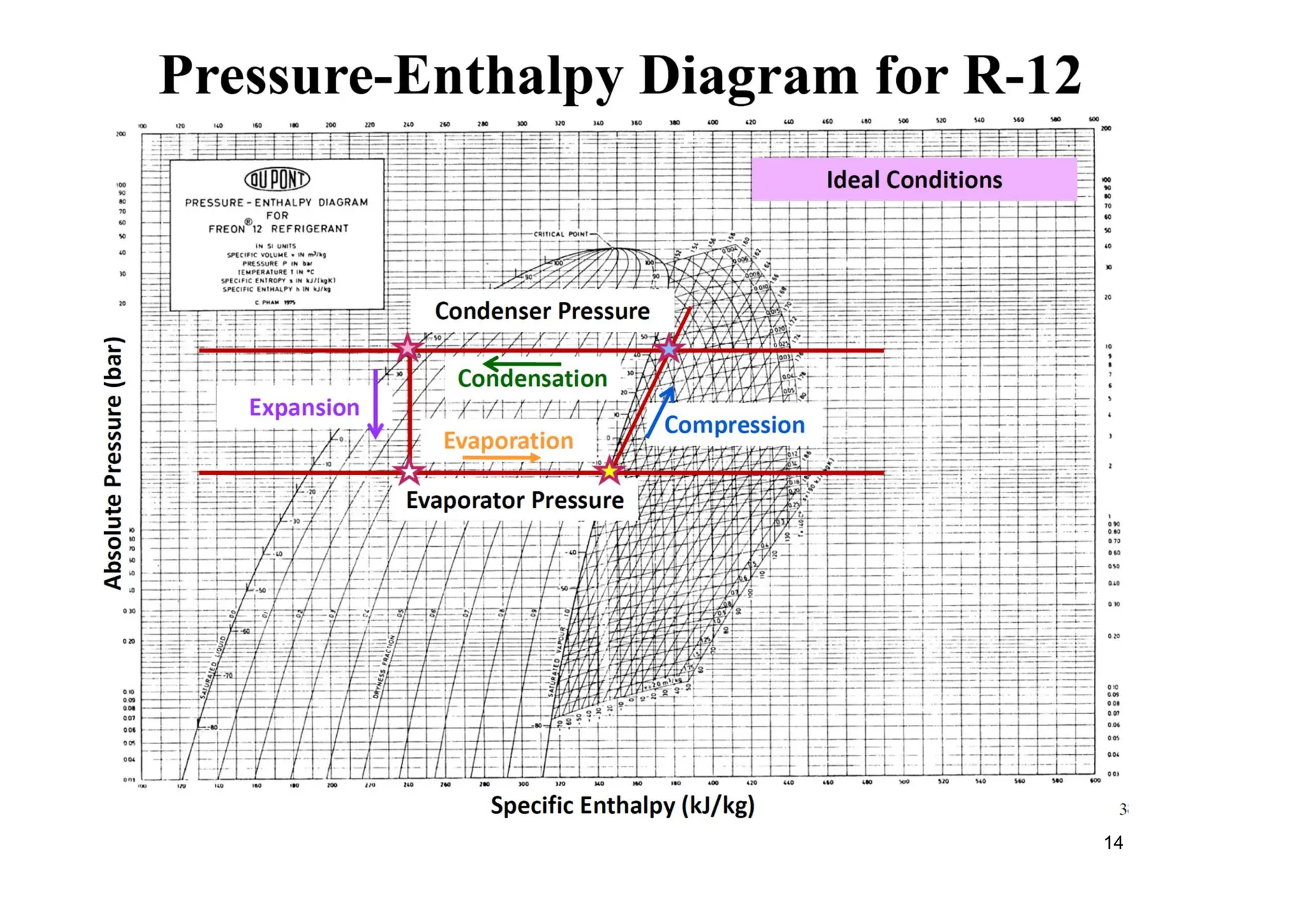

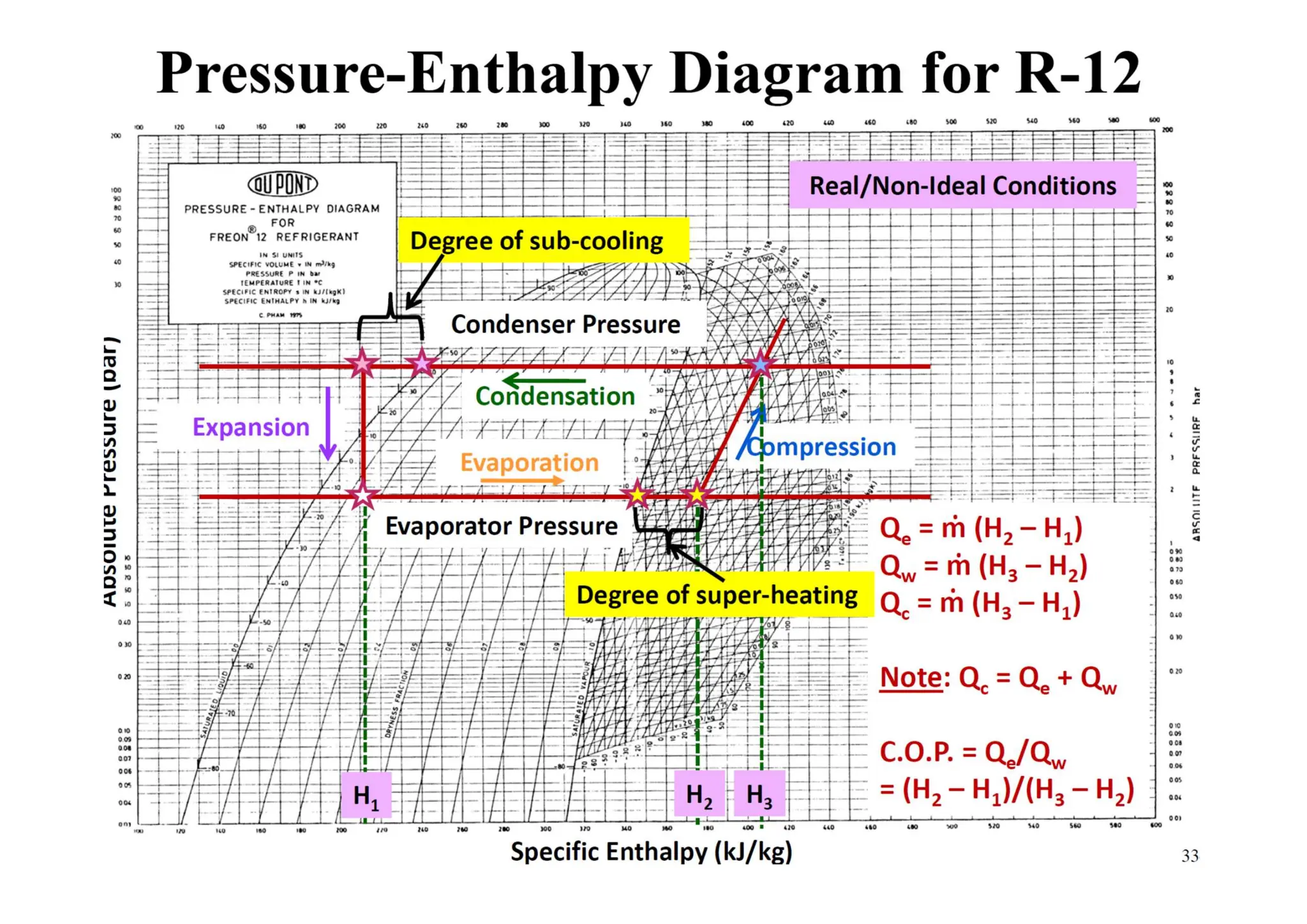

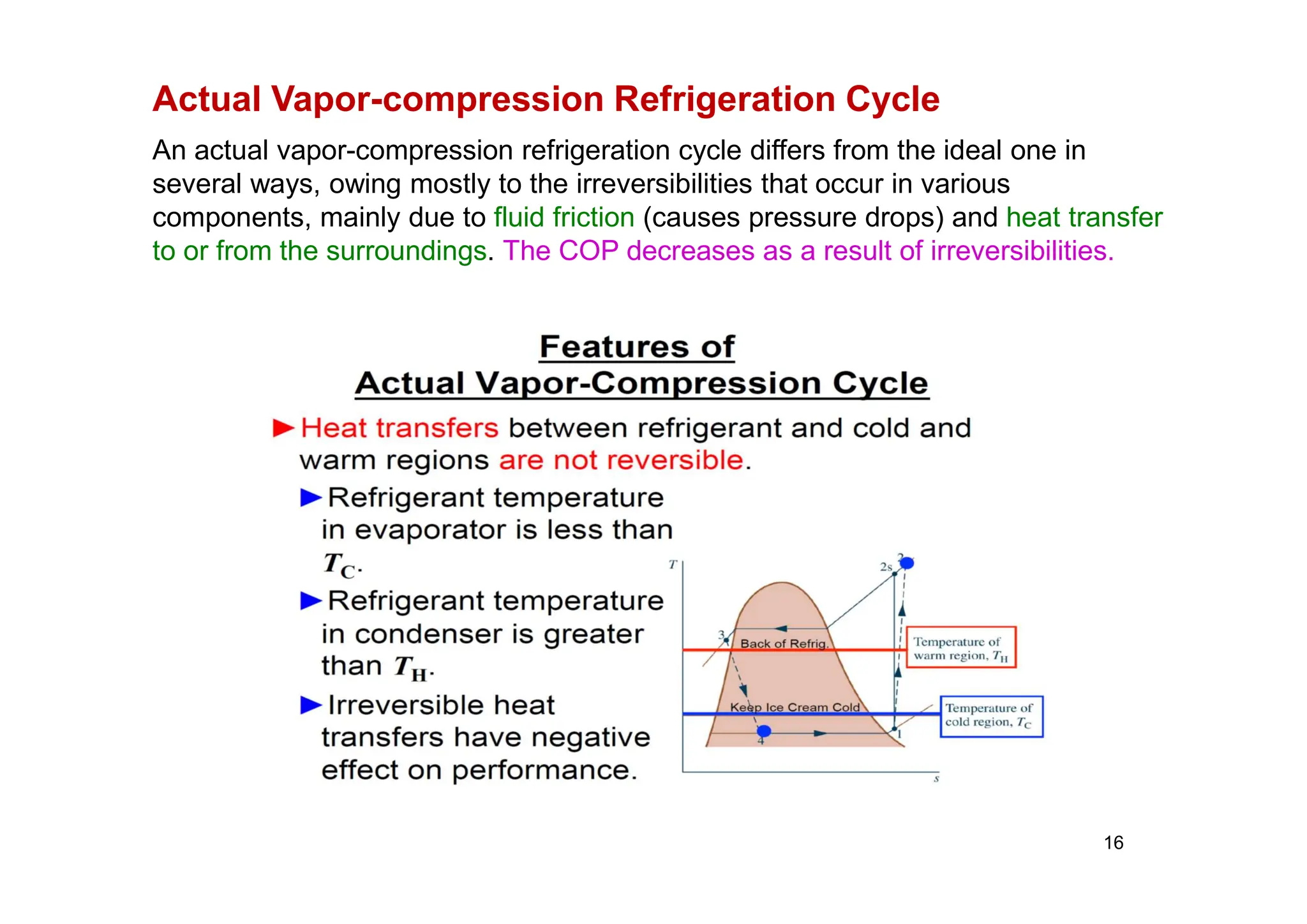

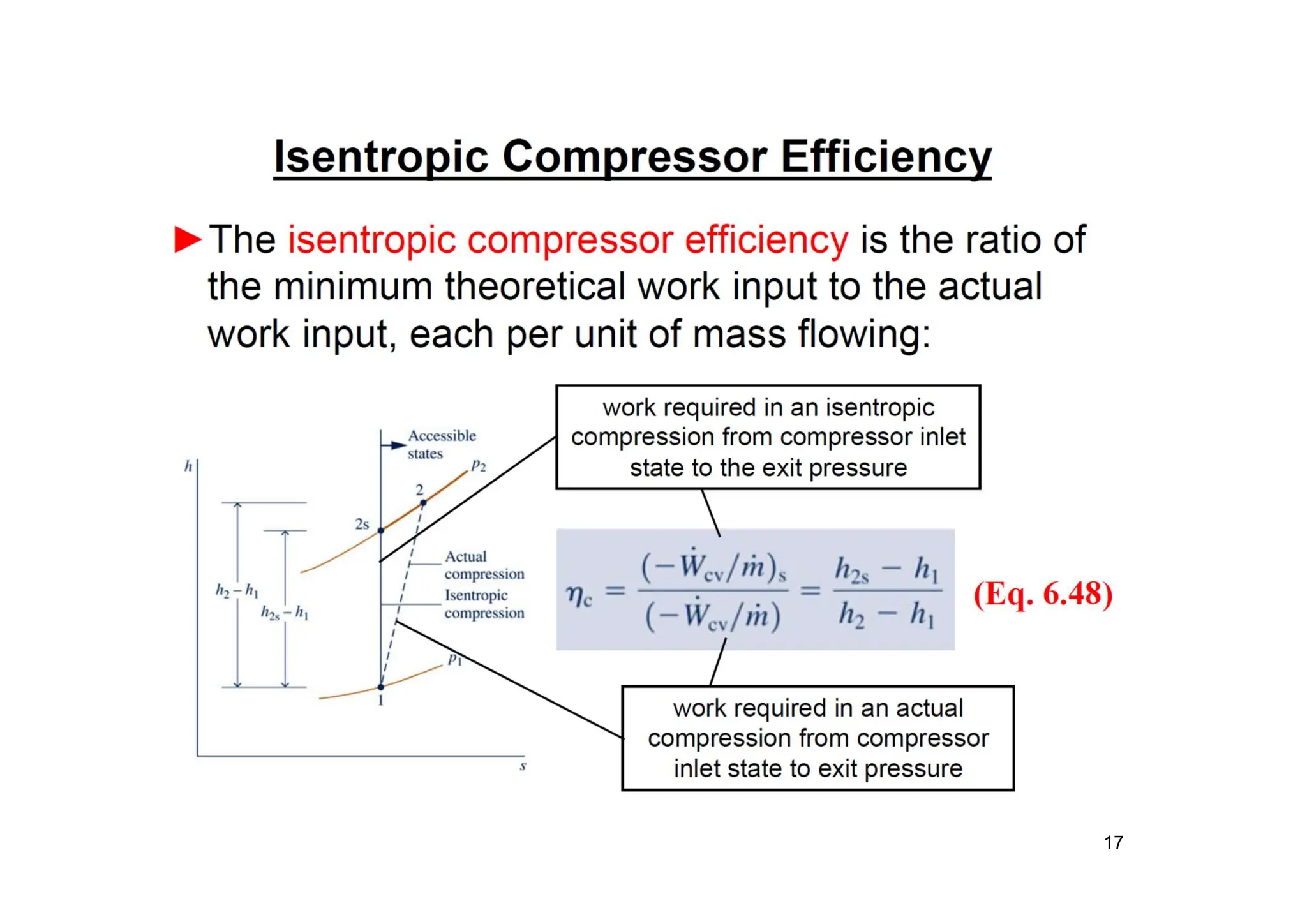

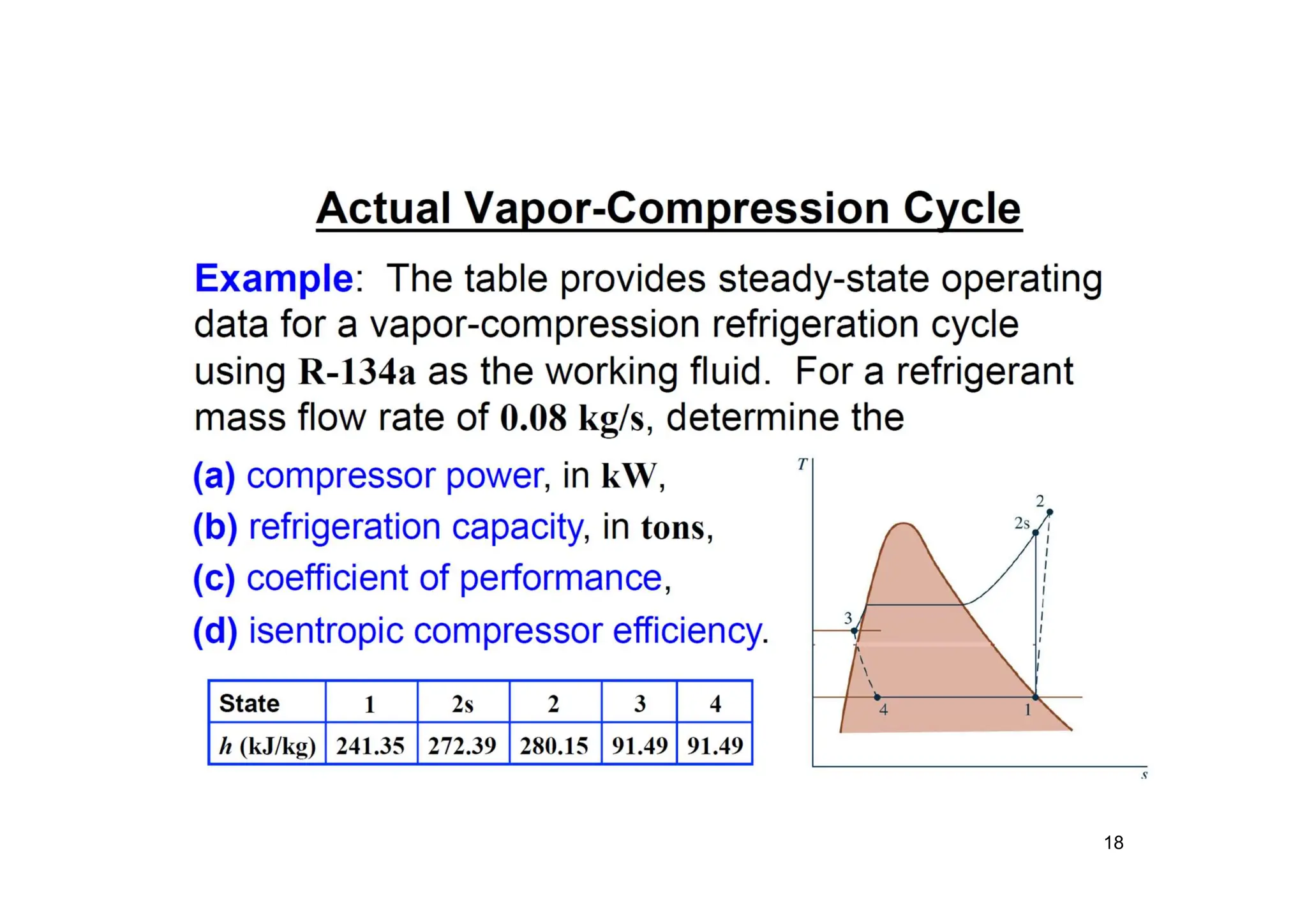

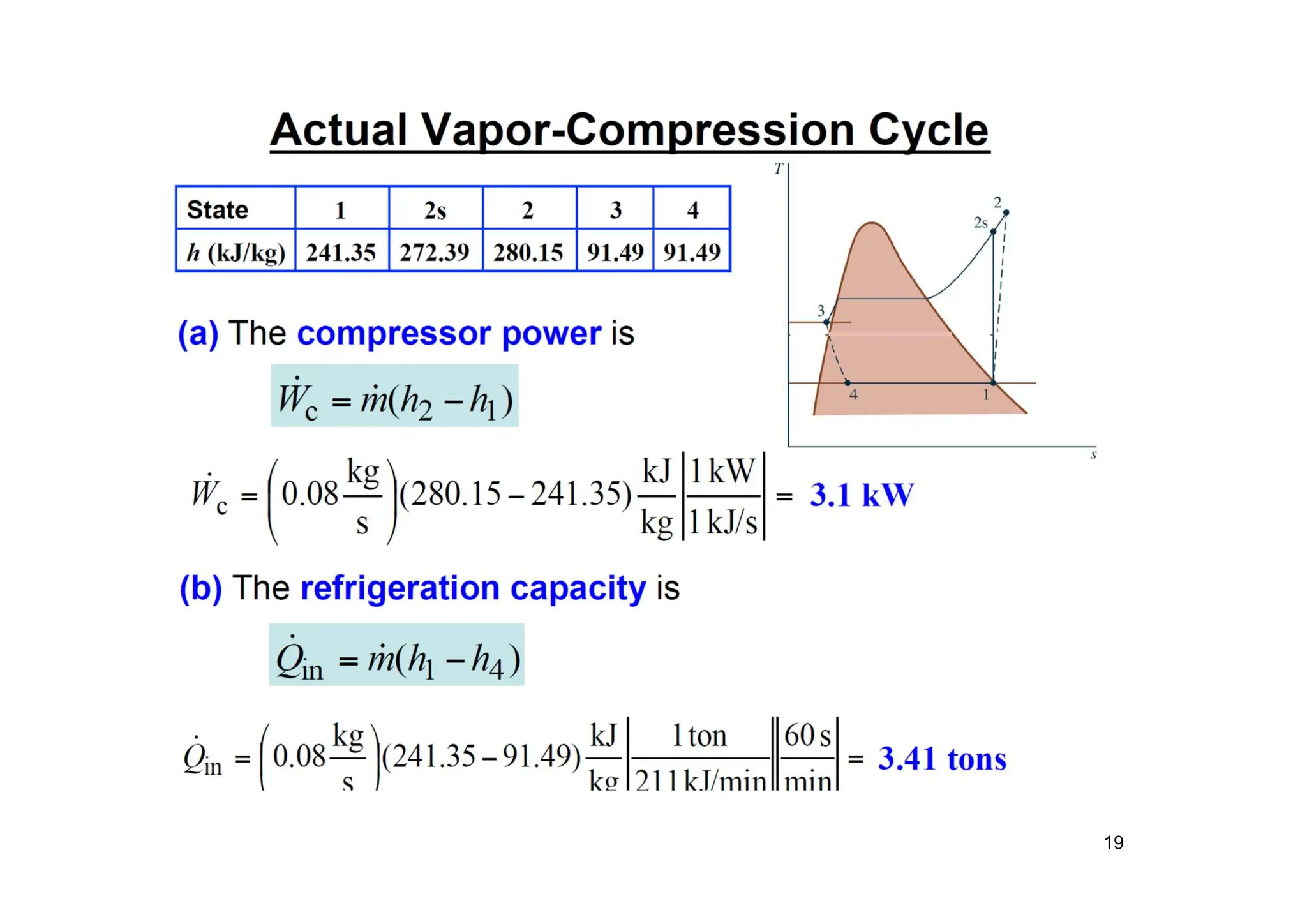

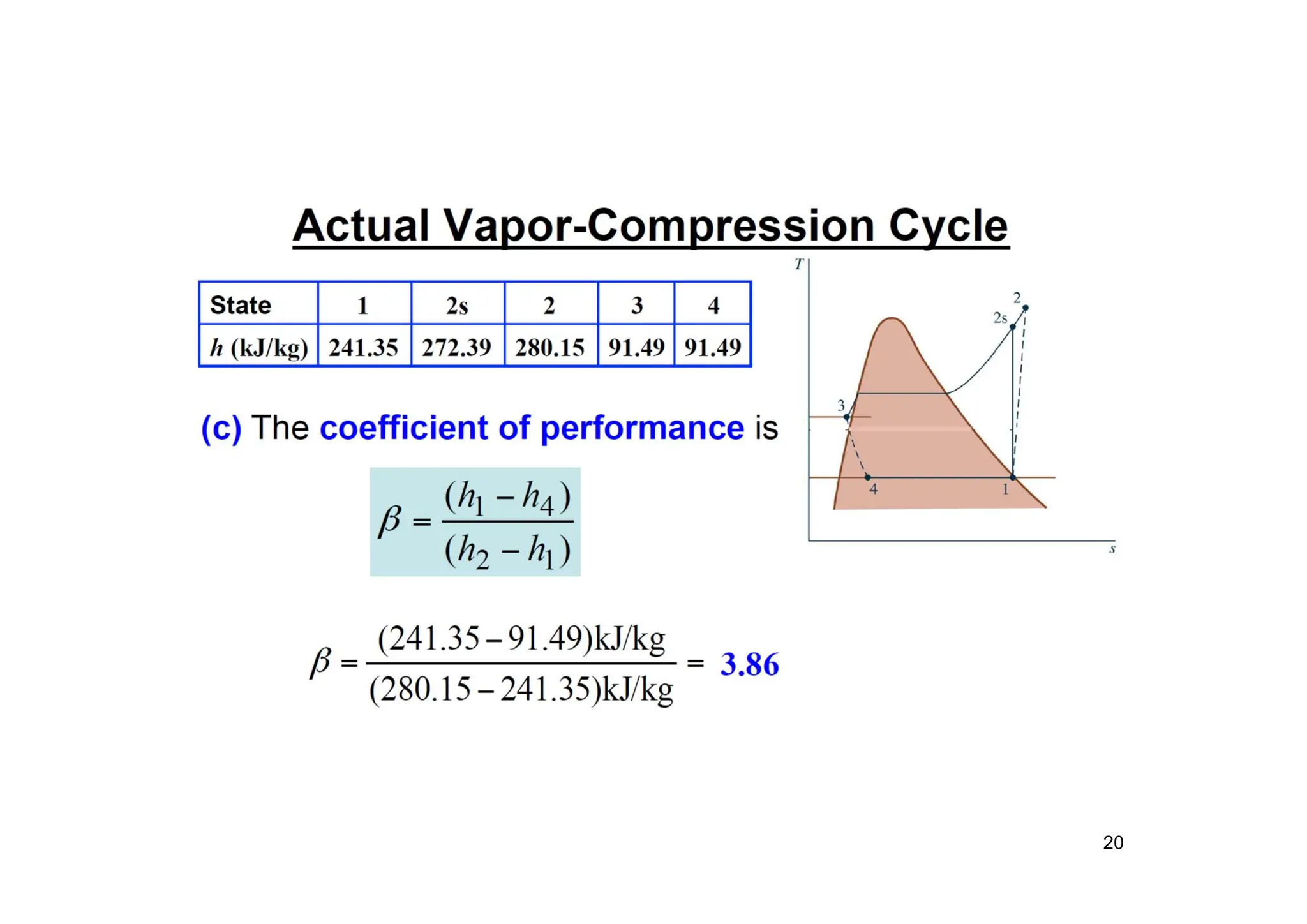

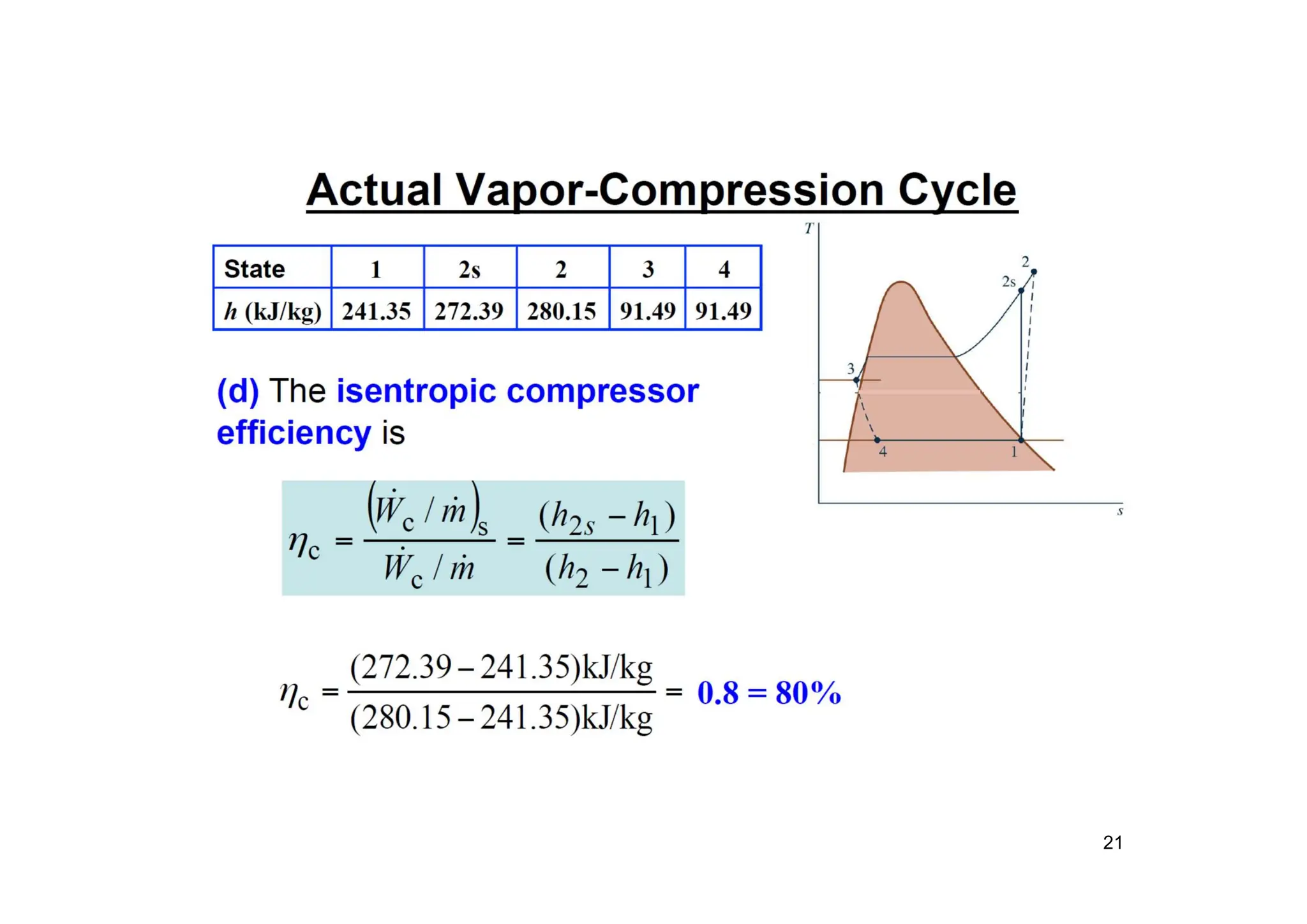

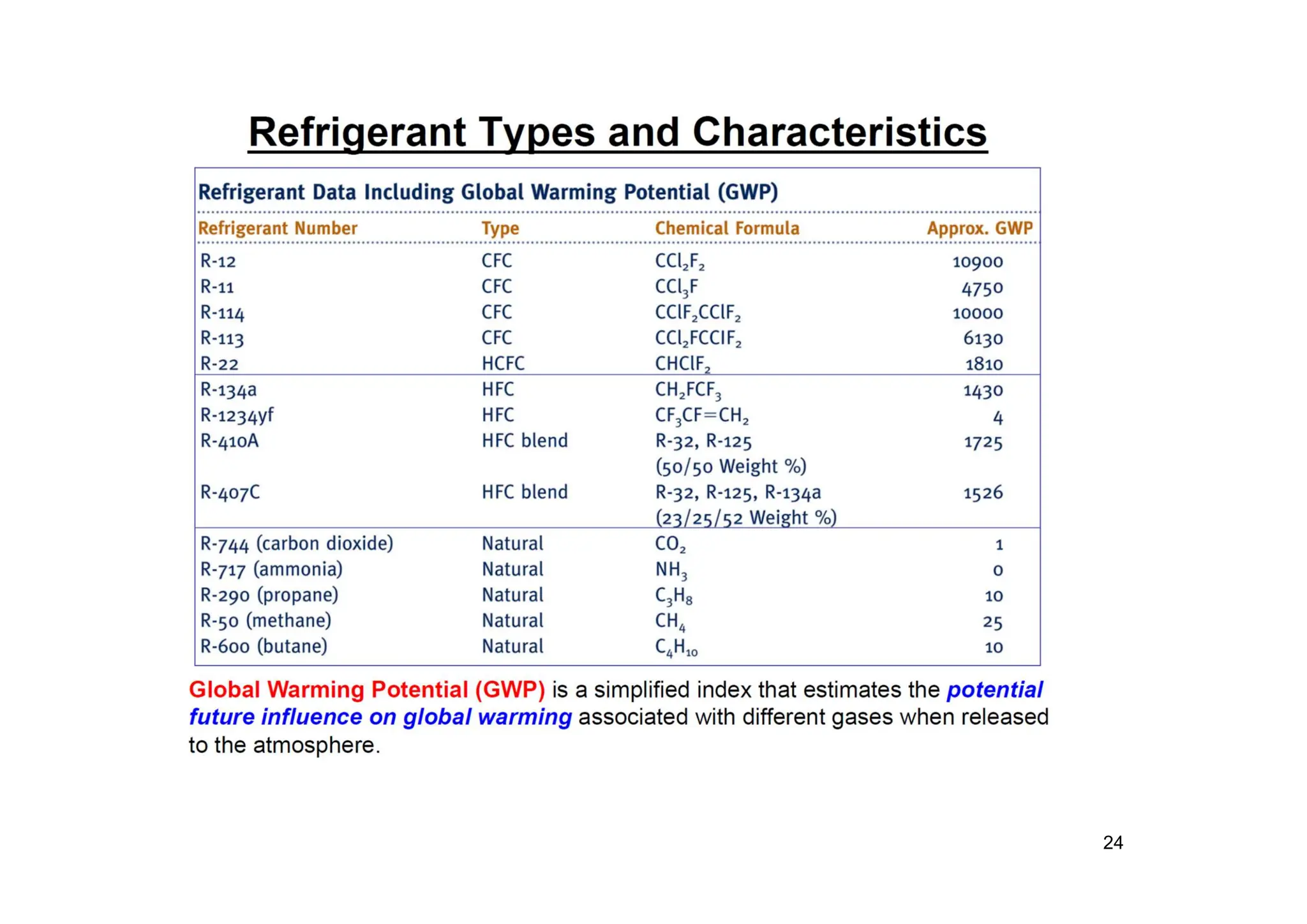

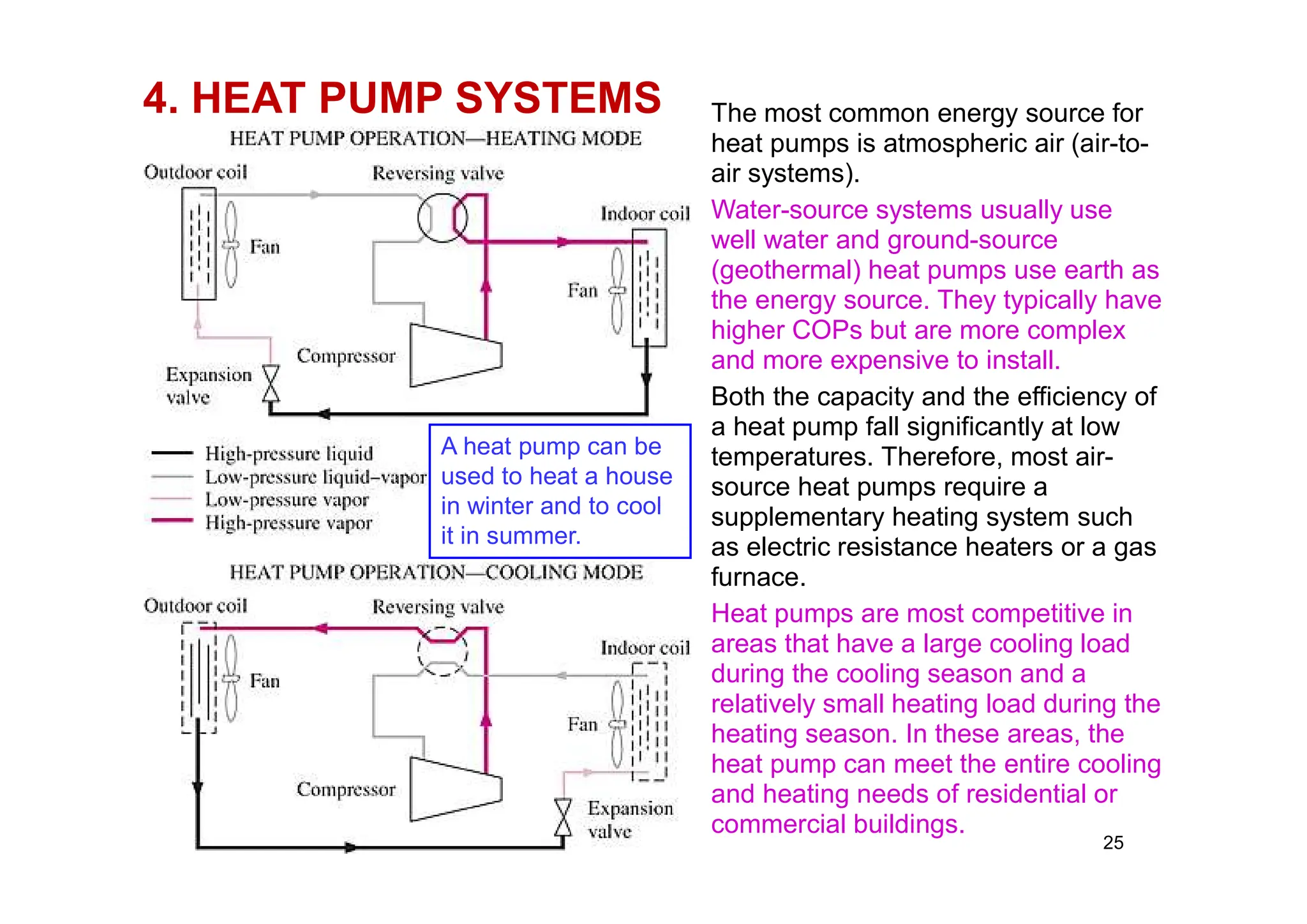

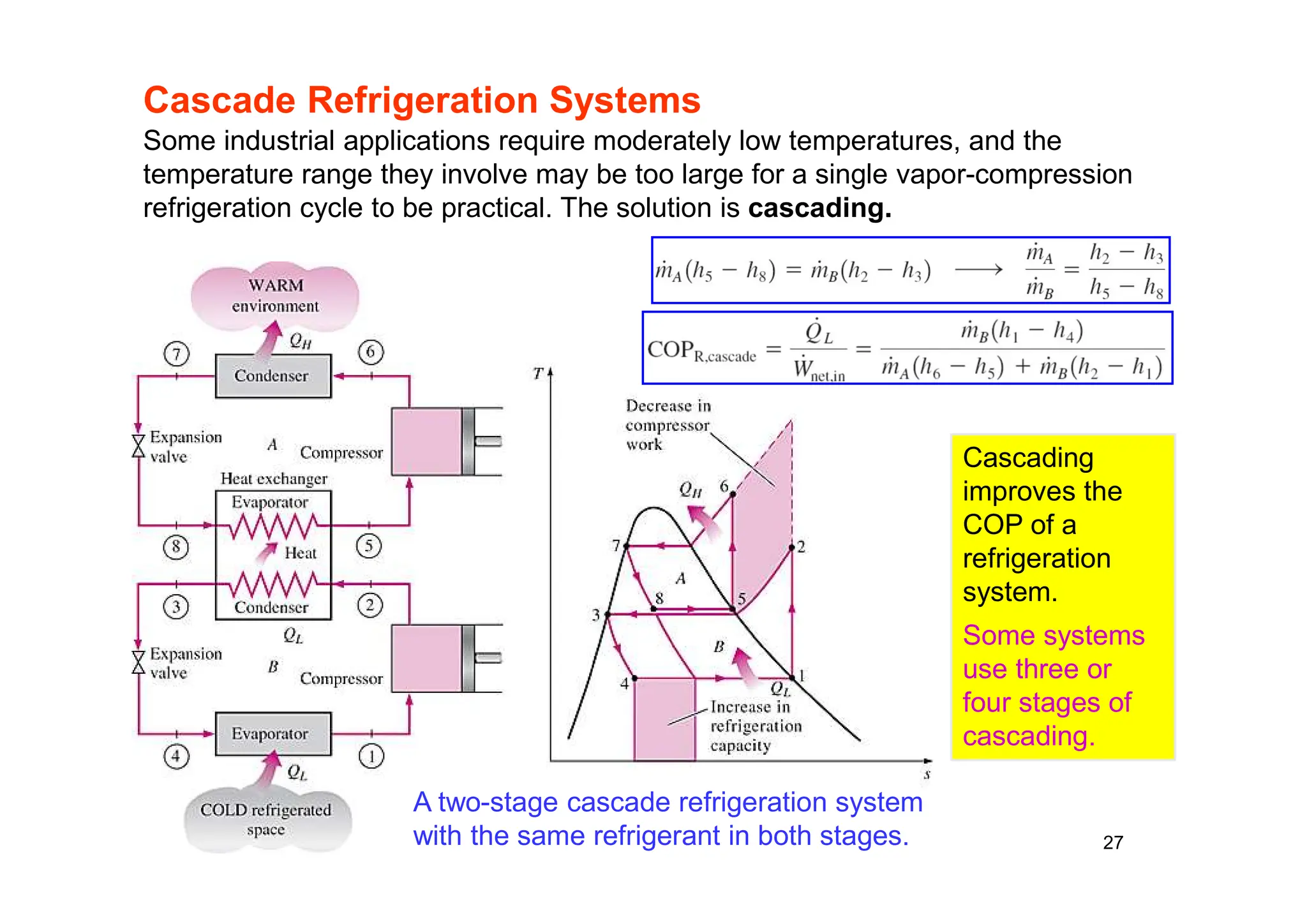

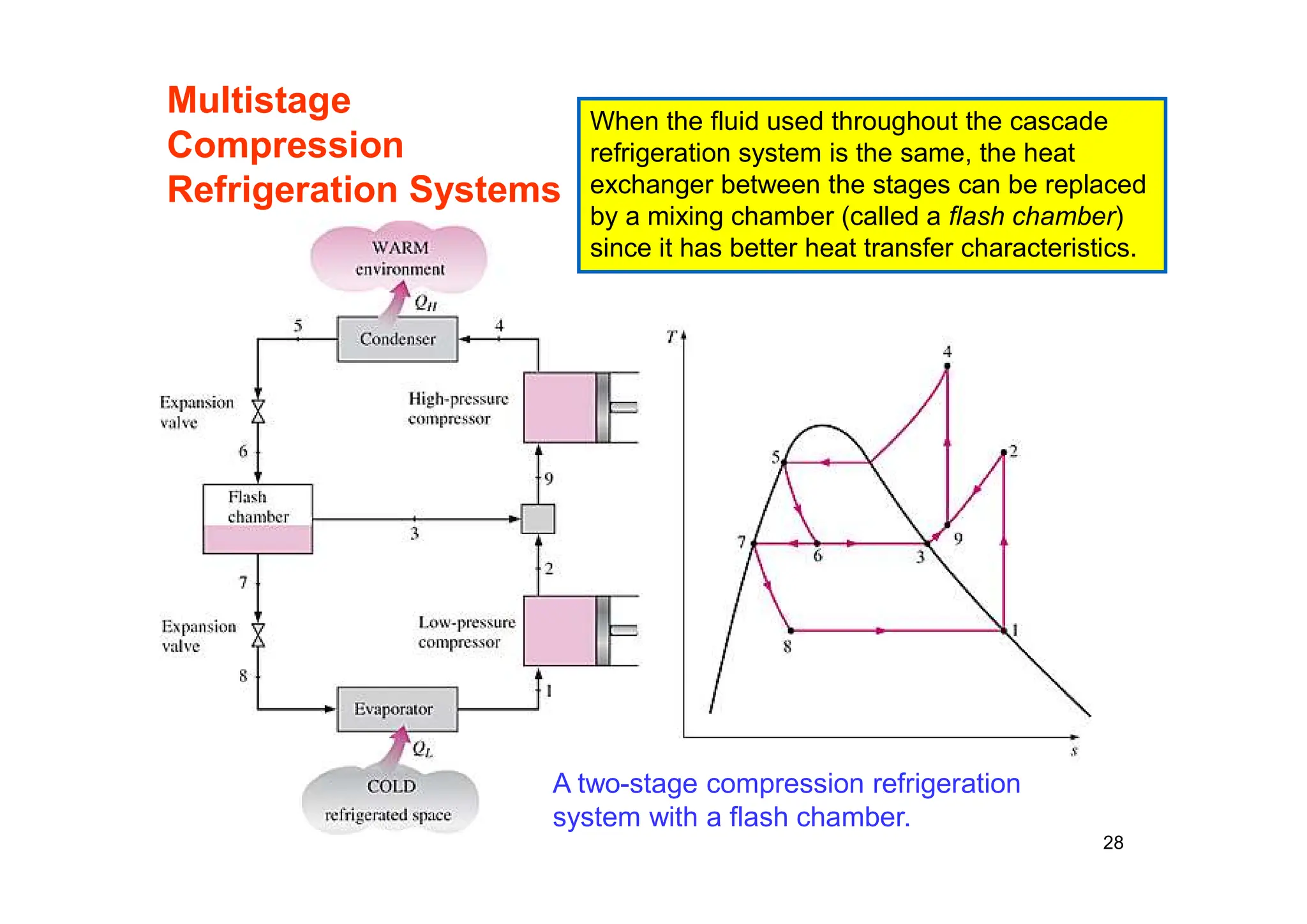

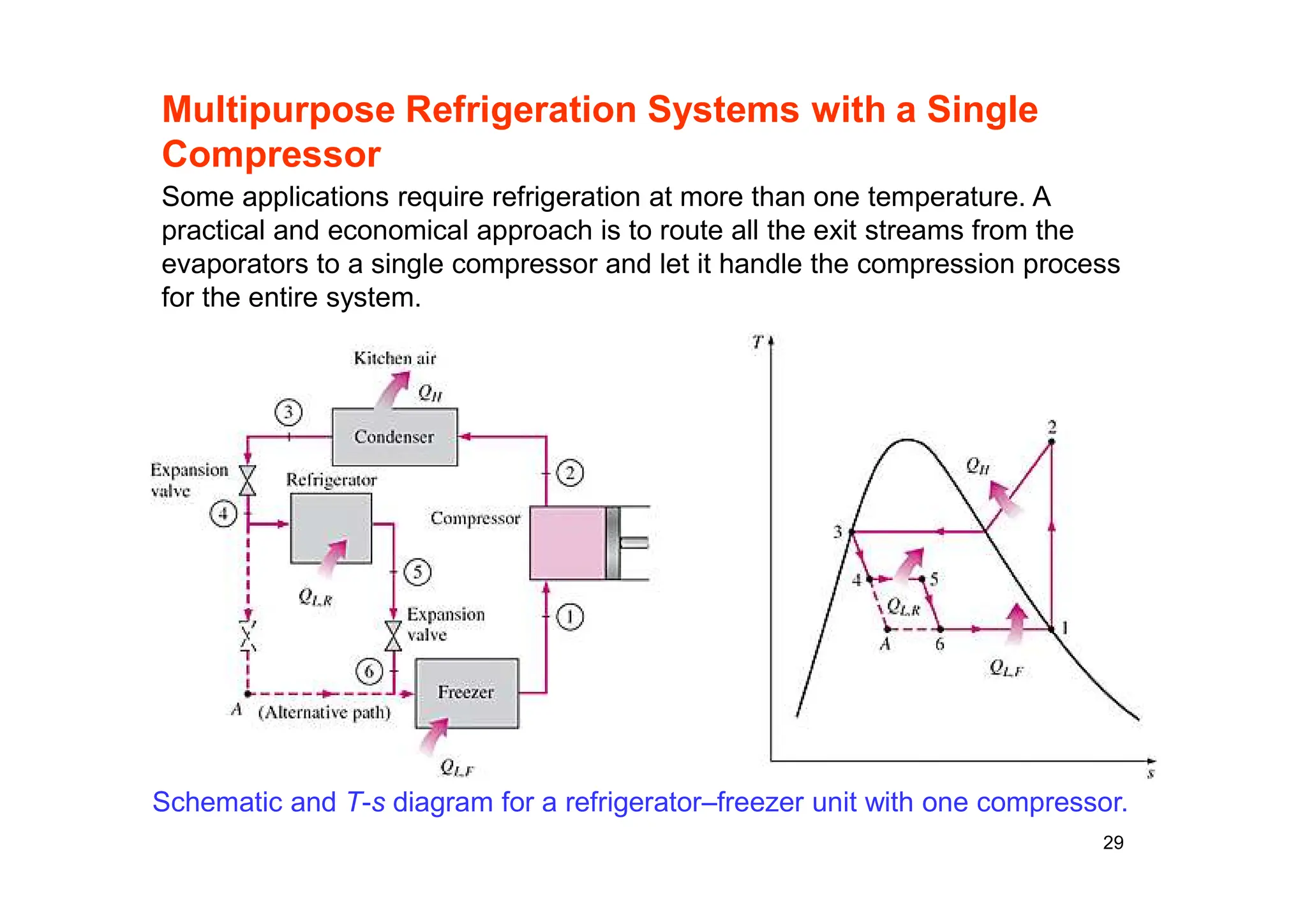

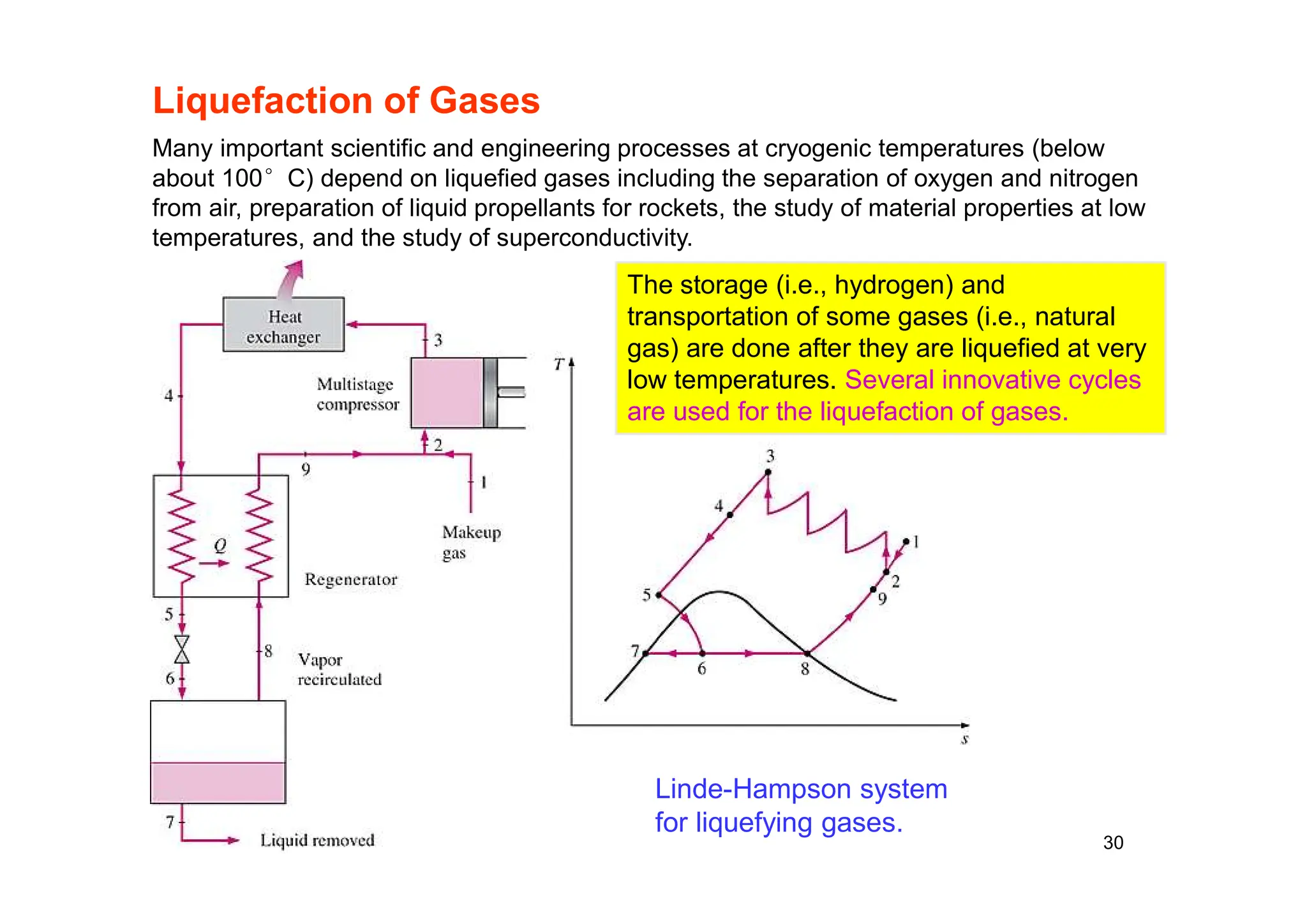

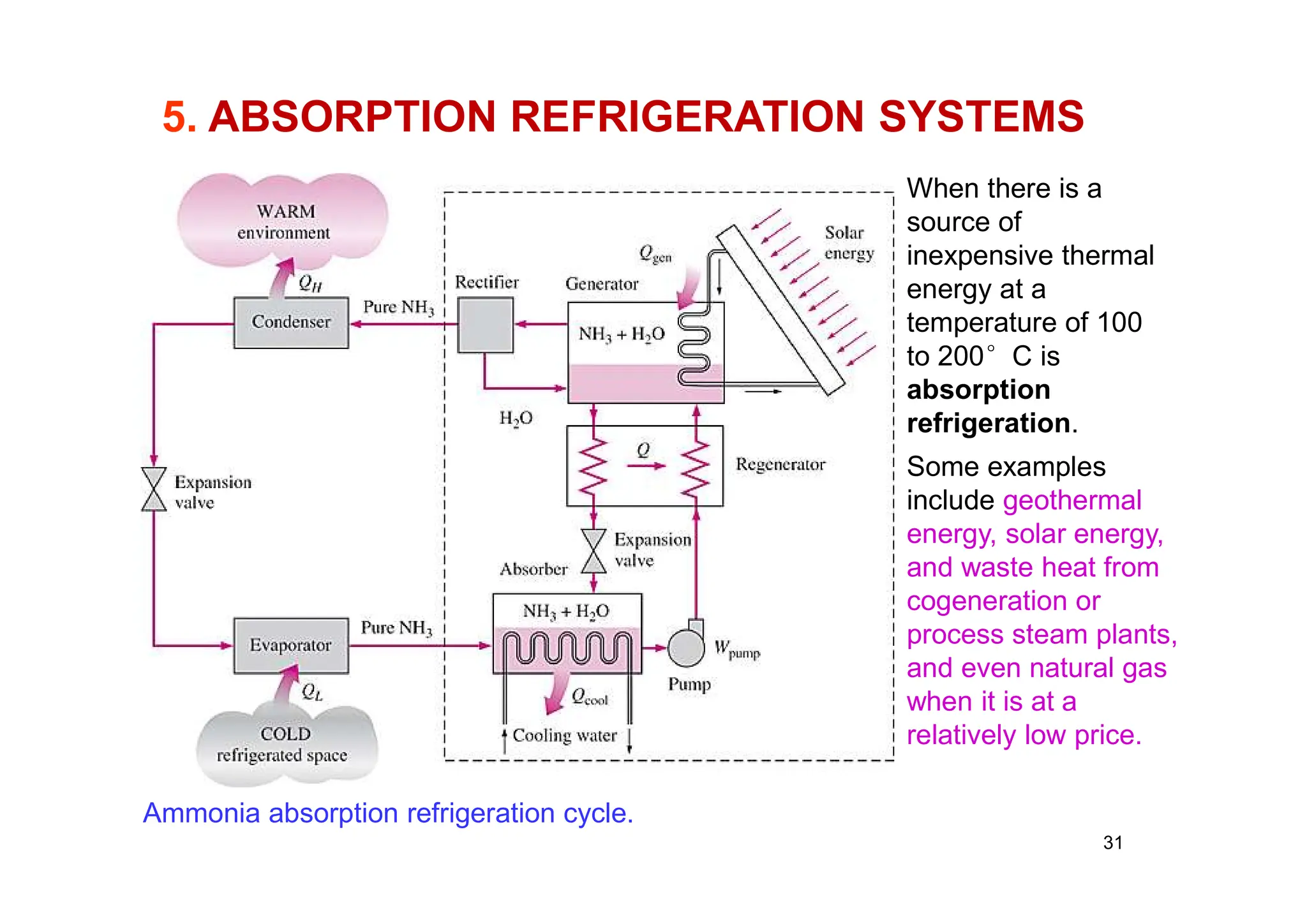

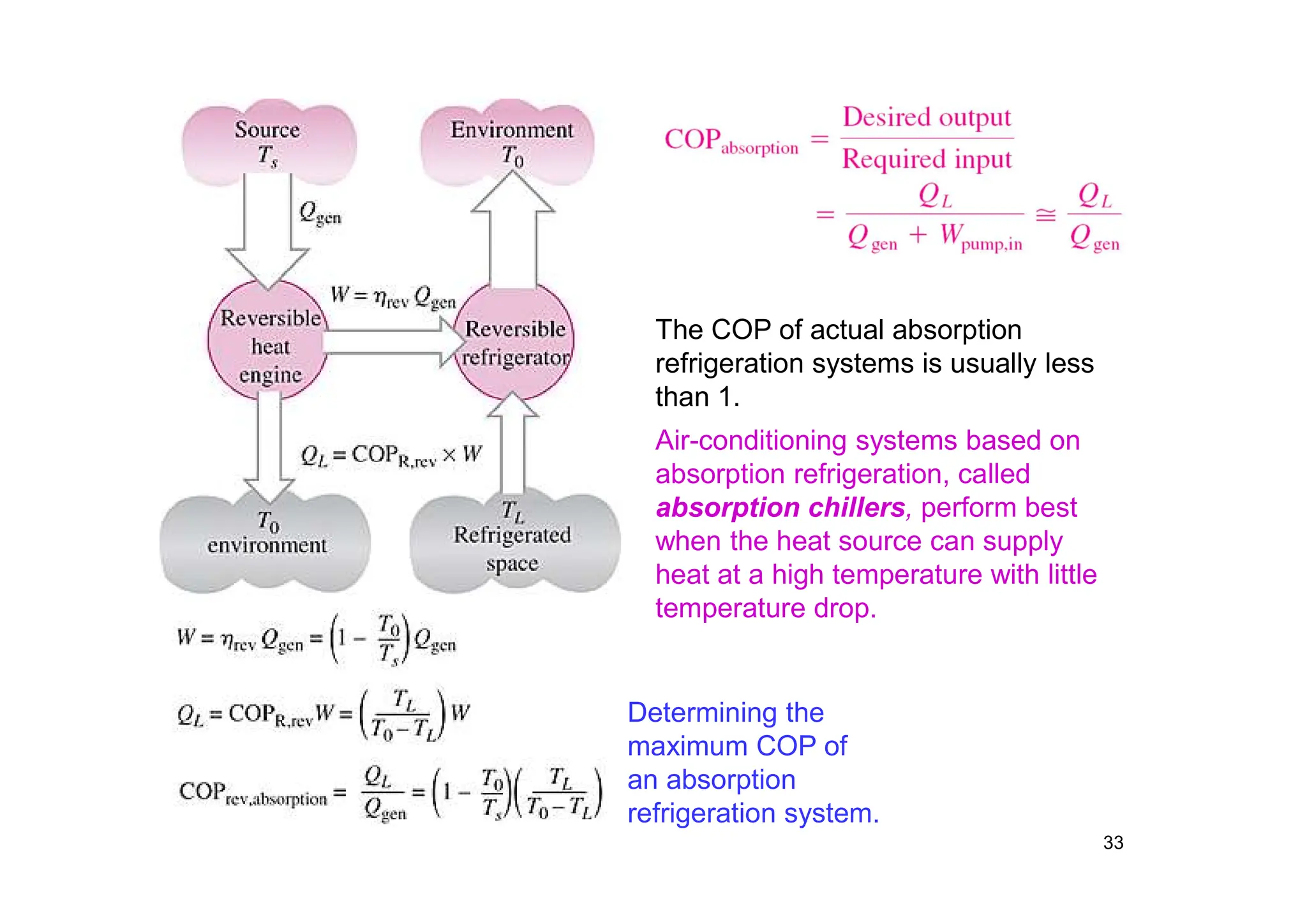

The document covers the principles and cycles of refrigeration, focusing on vapor-compression systems and their components. It discusses various types of systems such as heat pumps, innovative vapor-compression systems, and absorption refrigeration systems, along with performance metrics like the coefficient of performance (COP). Additionally, it highlights the selection of refrigerants and the importance of efficiency in both residential and industrial applications.