1) Moisture in the coke and ore burden must be removed before the reduction process can start in the blast furnace. Additional water is generated from coal and natural gas injectants.

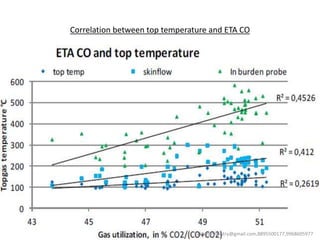

2) Wall areas are difficult to dry due to high burden thickness and lower gas temperatures from cooling losses. Skin flow temperatures and in-burden probes are used to monitor drying at the wall.

3) If moisture input increases, the temperature where reduction starts will descend, making the process less efficient and requiring more direct reduction in the lower furnace. Insufficient drying capacity can negatively impact furnace efficiency and productivity.