physical chemisrty of iron making slag

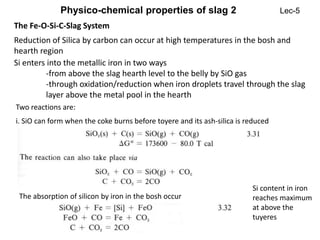

- 1. The Fe-O-Si-C-Slag System Si enters into the metallic iron in two ways -from above the slag hearth level to the belly by SiO gas -through oxidation/reduction when iron droplets travel through the slag layer above the metal pool in the hearth Two reactions are: i. SiO can form when the coke burns before toyere and its ash-silica is reduced The absorption of silicon by iron in the bosh occur Physico-chemical properties of slag 2 Lec-5 Reduction of Silica by carbon can occur at high temperatures in the bosh and hearth region Si content in iron reaches maximum at above the tuyeres

- 2. ii) Silica of the slag can be reduced by carbon containing liquid Fe passing through or in contact with the hearth slag Equilibrium Si content is several fold higher than that usually found in the BF BF metal Si fails to attain equilibrium due to the slow reaction rate Following assumptions are: a. Silica reduction by C is sluggish b. CO being a gas phase raise the evolution pressure c. Iron may not be saturated with C before enetring the slag layer

- 3. The dependence of Si distribution between the metal and slag on the slag basicity can be found from Ksi at any given temperature and SiO2 values for various basicity ratios

- 4. Fe-O-Mn-C Slag System Higher oxides of Mn are reduced in the shaft and only MnO descends in lower part of the furnace and is reduced at high temperature Mn absorption in iron at upper bosh is lower as compared to Si and S. Some Mn enters iron when the iron and MnO-containing liquid slag flow over the incandescent coke. Most of the Mn is reduced in the hearth Mn transfer occur during the C saturated iron droplets through the slag

- 5. The temperature dependence of KMn is not as high as that of Ksi The influence of pressure is not as high since Ksi is proportional to pCO squared With increasing CaO/SiO2 ratio, SiO2 decreases and MnO increases

- 6. S from coke is gasified in the shaft, in the bosh and in front of toyeres and absorbed by iron The absorbed S is removed by the hearth slag when sulfer-laden iron droplets pass through it Fe-O-S-C Slag System

- 7. The actual S content of BF iron is much higher than the equilibrium values High top pressure deteriorate the S removal while increasing slag basicity and temperature facilitate S removal The thermodynamic data show that the actual BF metal Si and Mn contents are much below and S content much above the equilibrium values with respect to C- saturated iron

- 8. The FeO-SiO2-Al2O3 System Gangue and flux = Silica, alumina, lime and magnesia Alumina, lime and magnesia are in solid state – interaction and solution is slow At high temperature, alumina and silica are sintered and alumina-silicates are more stable than the individual oxide At low temperature, the rate of lime dissolution is extremely slow because the materials are not finely divided The formation of first slag occurs through mixing of alumina-silicates by unreduced iron oxide. Primary slag: molten slag flows over lumps of lime and loses its iron oxides rapidly by the reaction of with coke at high temperature (these processes occur at belly and bosh where most of the silica and alumina from coke ash have not been released) Secondary or bosh slag: slag forms at the above of the toyere The final or hearth slag: When the coke ash released at the toyeres and the still undissolved lime are incorporated in the descending bosh slag which flows down to the hearth

- 9. Liquidus temperature of the alumina-silicates containing above 40% FeO is not more than about 12000C. As %FeO decreases, the melting point increases. The most favourable melting condition- gangue of an ore contains a SiO2/Al2O3 ratio 2.5-4/1

- 10. The CaO-SiO2-Al2O3 System The primary slag of relatively low melting- at lower part or in the belly contain FeO-containing silicates and aluminates with varying amount of lime As the slag descends, ferrous oxide is reduced Lime is continuously absorbed, the FeO-SiO2-Al2O3 system change to CaO- SiO2-Al2O3 The dissolution of lime lower the viscosity and liquidus temperature Primary slag runs down the bosh and loses its fluxing constituent FeO and increases the melting point Above the toyeres the resulting bosh slag mainly of CaO--SiO2-Al2O3 should be liquid and sufficiently fluid

- 11. For a smooth operation, the slag must be free-running and above the critical hearth temperature Slag composition selection: BF slag form from gangue and flux material and controls S, Si and Mn which need basicity ratio more than unity Normal basic BF slags between 1.0 to 1.5 and acid slag 0.8 to 1.0 Under BF conditions slags are as follows:

- 12. The CaO-MgO-SiO2-Al2O3 System Magnesia reduces the liquidus temperature and viscosity Desulphurization needs optimum slag composition with minimum viscosity which decreases with the increase of ratio basic to acid The lowest silica with optimum desulphurization will be 44% CaO, 14%MgO, 32%SiO2 and 10% Al2O3 MgO addition to CaO-SiO2-Al2O3 decrease the viscosity