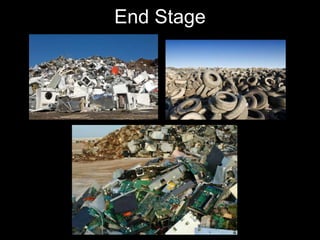

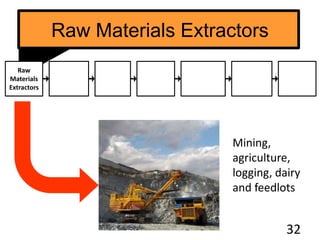

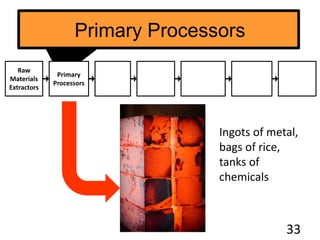

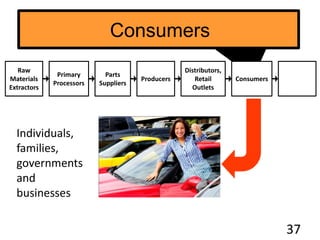

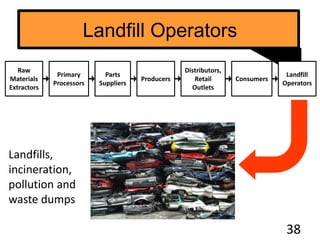

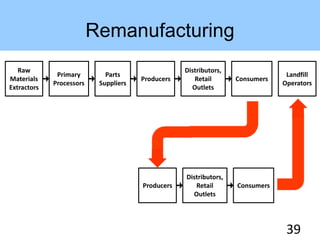

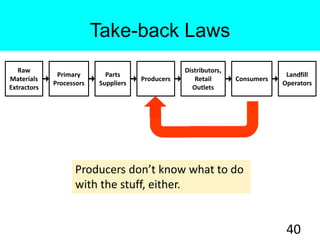

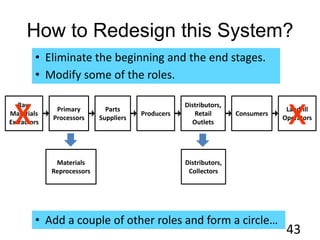

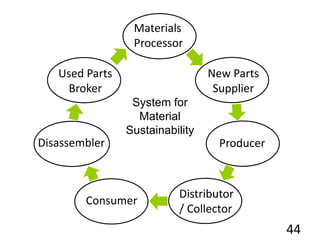

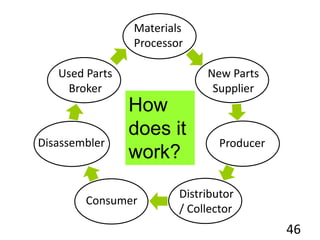

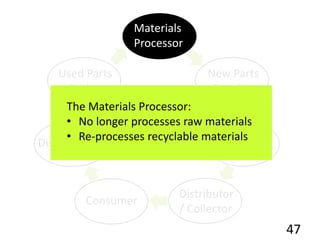

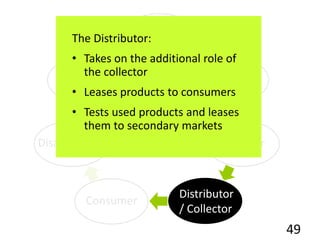

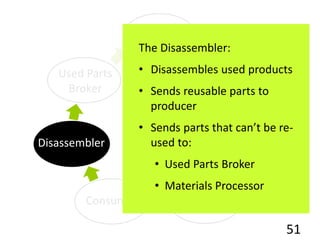

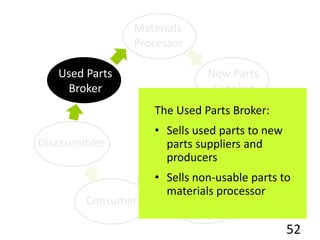

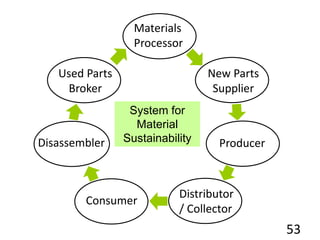

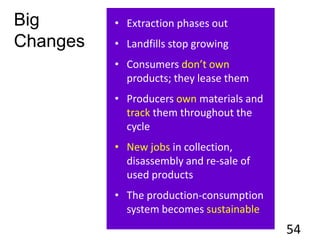

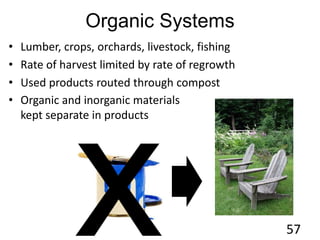

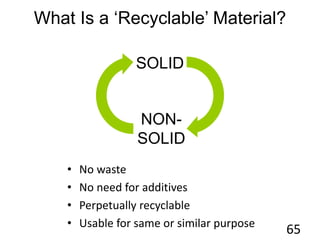

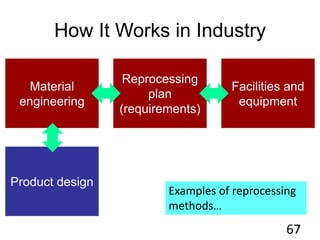

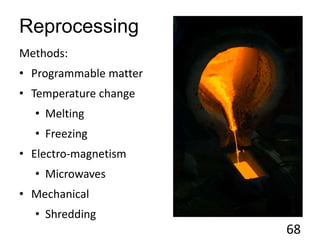

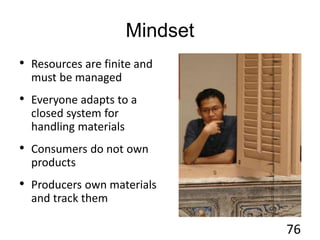

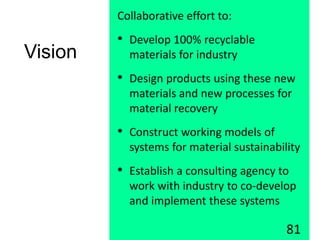

The document presents a comprehensive plan for achieving complete recycling through innovative systems and a new mindset focused on sustainability. It discusses the materials needed, the current challenges in the recycling process, and introduces a new cyclical production-consumption model that emphasizes leasing over ownership. The Institute for Material Sustainability aims to collaborate with industries to develop 100% recyclable materials and implement these sustainable systems.