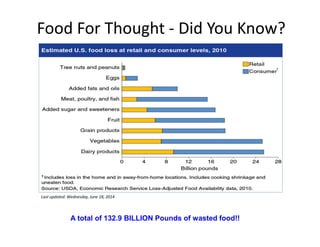

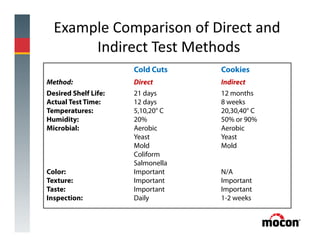

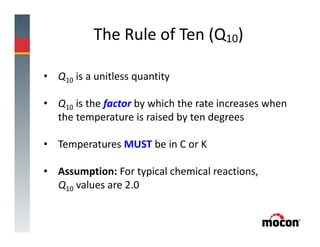

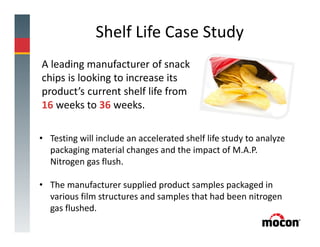

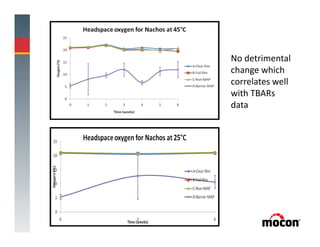

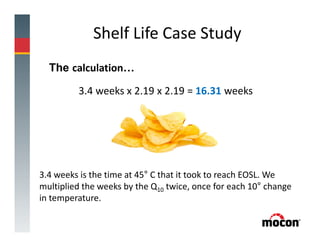

This document summarizes the key steps in conducting a shelf life study: defining shelf life and why studies are important, determining test methods (direct or indirect), establishing storage conditions and testing intervals, selecting product samples and protocol, and applying the Rule of Ten (Q10) to calculate shelf life from accelerated studies. It also provides an example shelf life case study on snack chips that demonstrates applying these methods to determine optimal packaging and gas flushing to increase shelf life from 16 to 36 weeks. Maintaining consistent quality requires ongoing testing through a quality control program.