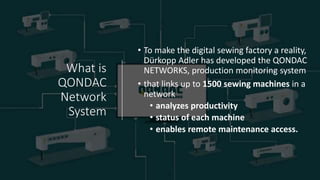

This document discusses the use of real-time data in the garment industry. It defines real-time data as information delivered immediately after collection without delay. The garment industry has lagged other industries in adopting new technologies. Real-time data sharing is important to ensure smooth workflow within and between departments. Real-time production data allows managers to make quick decisions and check reports from anywhere. A system called QONDAC Networks from Durkopp Adler links sewing machines in a network to analyze productivity and enable remote maintenance.