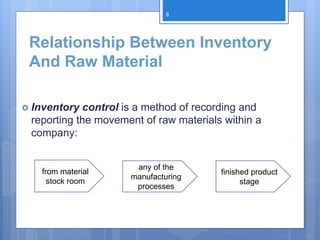

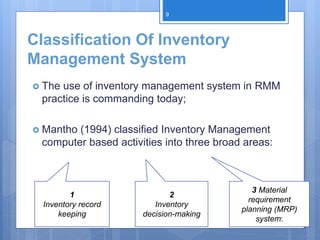

The document discusses raw material management and inventory control in manufacturing organizations. It addresses several key points:

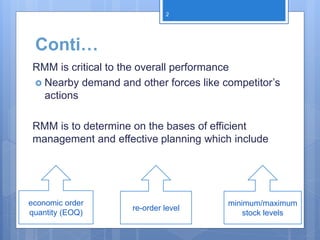

1) Efficient raw material management is critical to the overall performance of a manufacturing organization. It involves determining economic order quantities, re-order levels, and minimum/maximum stock levels.

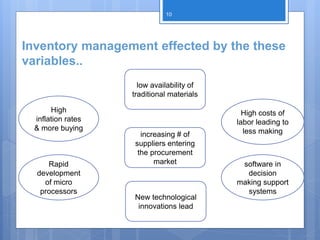

2) Effective inventory control, including forecasting, planning, inventory control, scrap control and disposal, is important for efficient operations, profitability, and survival.

3) Maintaining the right stock levels can improve working capital utilization and profitability. Both overstocking and understocking raw materials can cause problems.

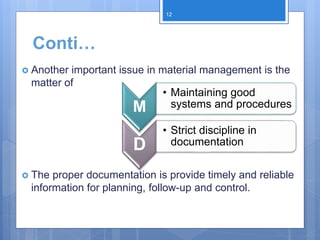

4) Proper documentation and systems are needed to provide reliable information for planning, follow-up