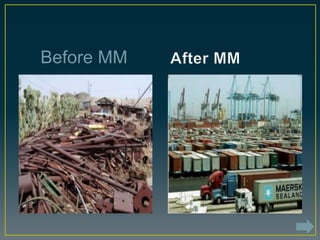

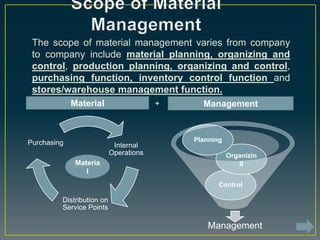

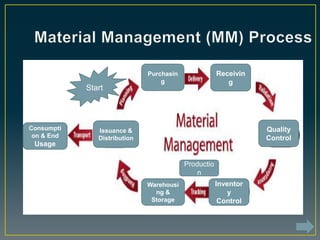

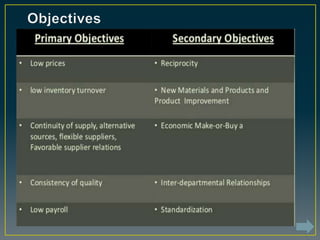

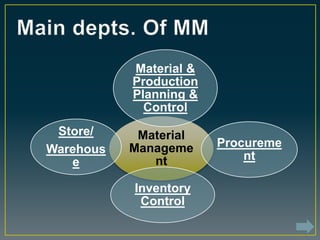

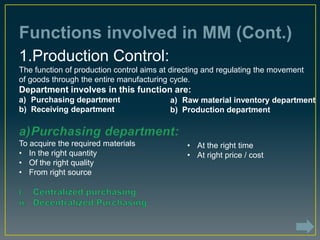

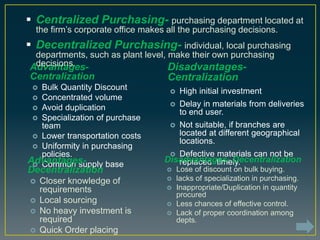

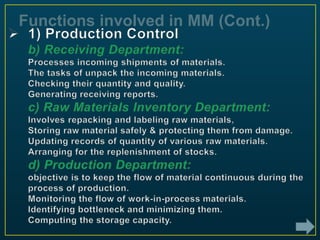

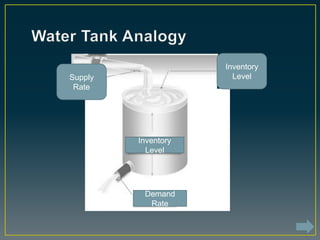

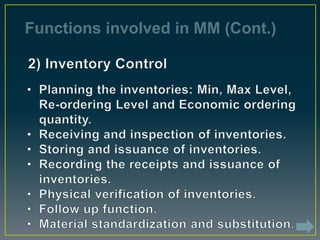

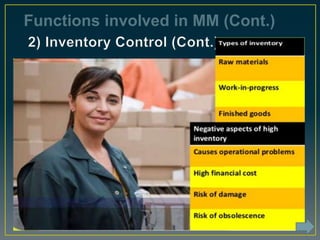

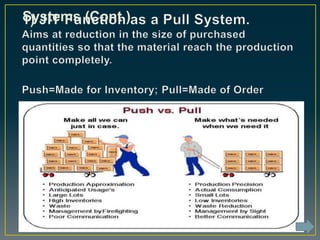

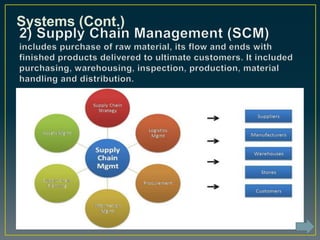

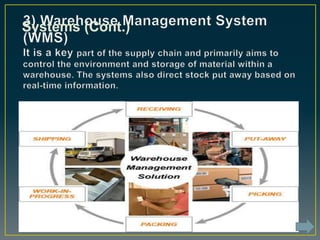

This document discusses material management (MM) in a manufacturing organization. It describes the scope of MM, which includes planning, organizing, controlling production, purchasing, inventory control, and warehouse management. The objectives of MM are to smooth production flow, reduce costs, save labor time, and utilize resources efficiently. Key functions of MM are production control, inventory control, and material handling. It also discusses various systems that support MM like JIT, SCM, and WMS. Challenges in implementing MM include selecting vendors, demand forecasting, product line diversification, and information management.