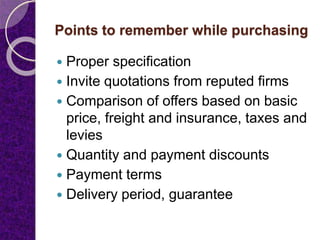

Material management in healthcare aims to provide the necessary drugs, supplies, and equipment for health services delivery. It involves planning, organizing, and controlling the flow of materials from purchase to distribution. Around 40% of healthcare funds are spent on materials. Effective material management is important to supply quality materials at the right time, place, quantity and cost. Inventory control techniques like ABC, FSN, VED, and SDE analyses help classify items based on various criteria to optimize inventory levels and reduce costs while avoiding stockouts. The right analysis and classification allows prioritizing high-cost vital items for close monitoring and low-cost non-essential items for less stringent control.