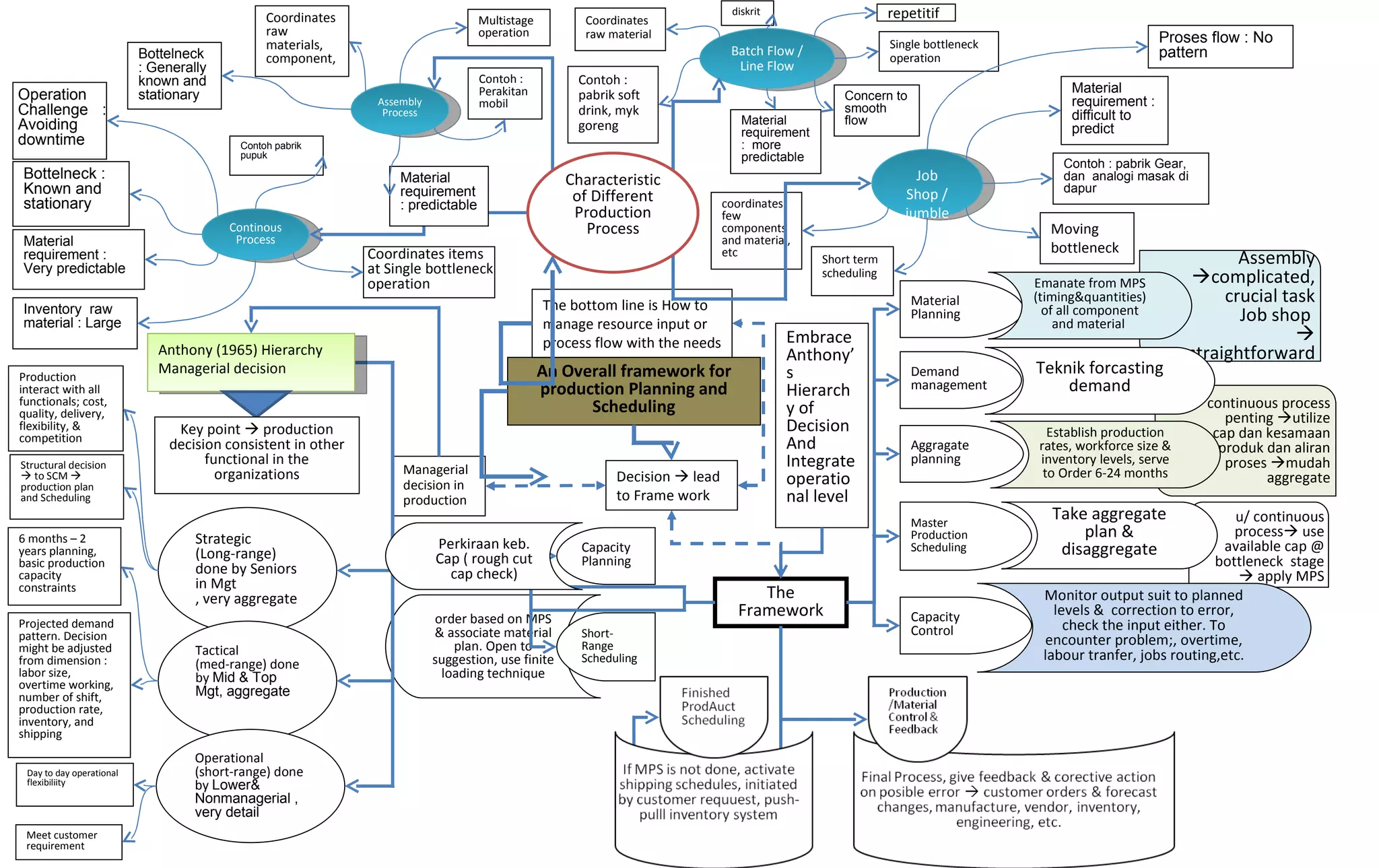

This document discusses production planning and scheduling. It begins by describing characteristics of different production processes like batch, line, and job shop flows. It then discusses challenges like avoiding downtime and managing bottlenecks. Material requirements and inventory are discussed as predictable or unpredictable depending on the process. The rest of the document outlines frameworks for production planning including Anthony's hierarchy of planning horizons from strategic to tactical to operational. Capacity planning, master production scheduling, and capacity control are also mentioned.