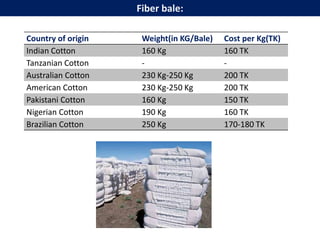

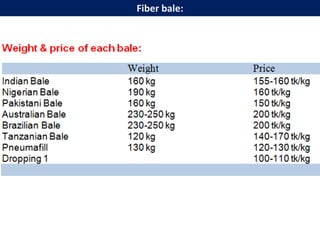

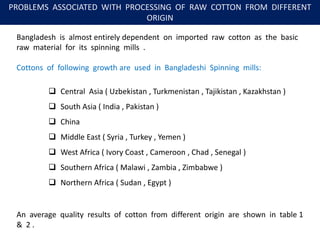

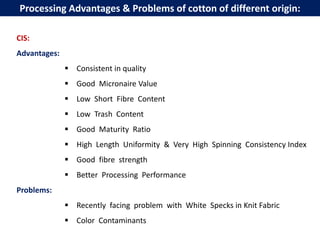

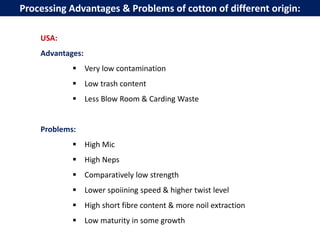

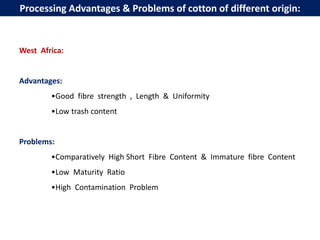

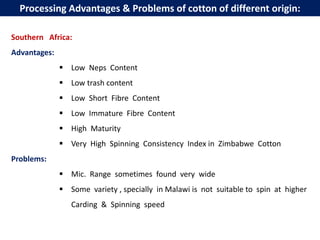

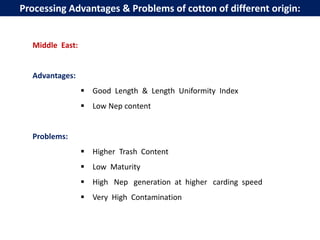

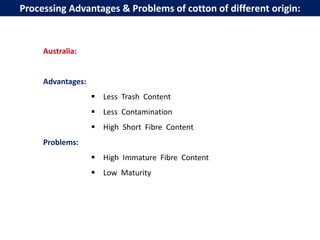

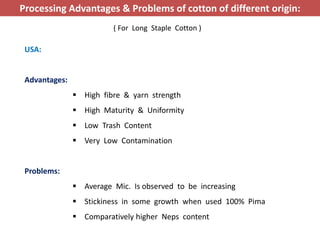

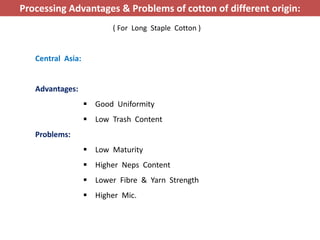

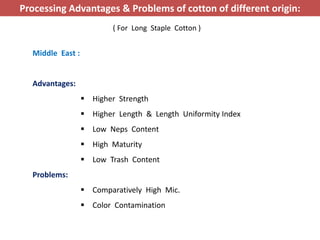

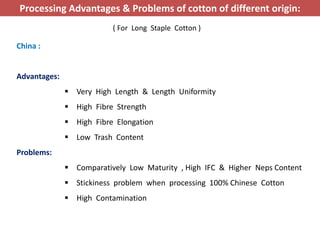

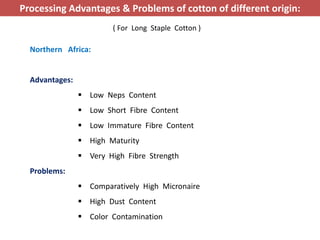

SIM Group uses cotton fibers to produce low count yarns between 7-20 Ne. They use different types of raw cotton and wastage from various countries in their production. The main raw cotton brands used are Indian, Tanzanian, and Brazilian cotton. The document discusses the different raw materials and wastages used, including doffing-1, doffing-2, roving crash, pneumafil, and flat strip. It also provides details on the country of origin, weight, and cost of various raw cotton types. Finally, it outlines some of the processing advantages and problems associated with cotton from different origins.