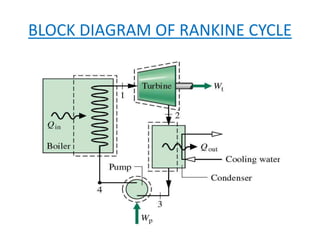

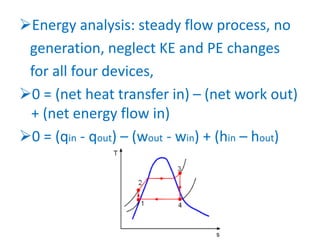

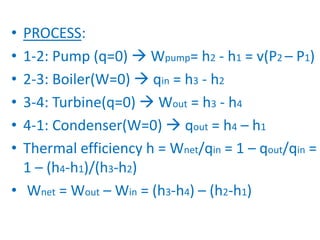

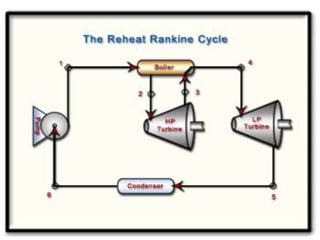

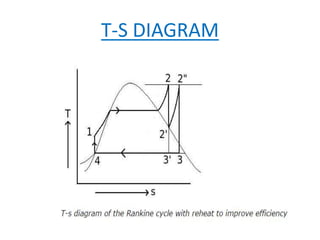

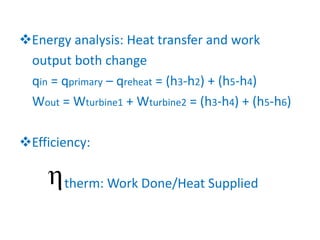

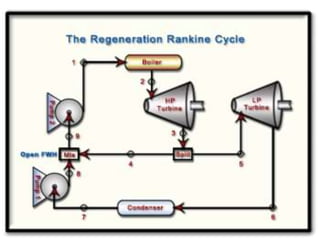

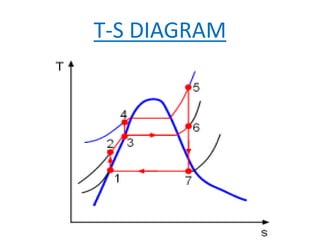

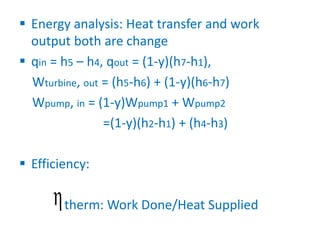

The document discusses the Rankine cycle, which is used to convert heat into work. It defines the Rankine cycle and explains that it uses water in a closed loop to generate about 90% of the world's electric power. It describes the ideal Rankine cycle and how real cycles differ by being non-reversible. It then discusses developments like the reheat and regeneration Rankine cycles, which aim to increase efficiency. The reheat cycle reheats steam after the first turbine, while regeneration heats liquid using a regenerator before entering the boiler. Diagrams illustrate the temperature-entropy processes of each cycle type.