Quality control tests of suppository ...

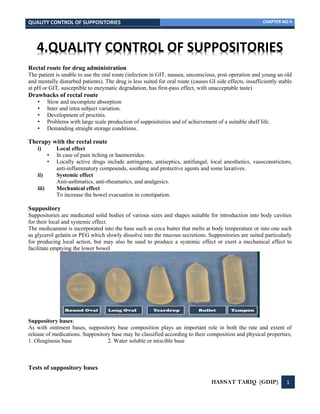

- 1. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 1 4.QUALITY CONTROL OF SUPPOSITORIES Rectal route for drug administration The patient is unable to use the oral route (infection in GIT, nausea, unconscious, post operation and young an old and mentally disturbed patients). The drug is less suited for oral route (causes GI side effects, insufficiently stable at pH or GIT, susceptible to enzymatic degradation, has first-pass effect, with unacceptable taste) Drawbacks of rectal route • Slow and incomplete absorption • Inter and intra subject variation. • Development of proctitis. • Problems with large scale production of suppositories and of achievement of a suitable shelf life. • Demanding straight storage conditions. Therapy with the rectal route i) Local effect • In case of pain itching or haemorrides. • Locally active drugs include astringents, antiseptics, antifungal, local anesthetics, vasoconstrictors, anti-inflammatory compounds, soothing and protective agents and some laxatives. ii) Systemic effect Anti-asthmatics, anti-rheumatics, and analgesics. iii) Mechanical effect To increase the bowel evacuation in constipation. Suppository Suppositories are medicated solid bodies of various sizes and shapes suitable for introduction into body cavities for their local and systemic effect. The medicament is incorporated into the base such as coca butter that melts at body temperature or into one such as glycerol gelatin or PEG which slowly dissolve into the mucous secretions. Suppositories are suited particularly for producing local action, but may also be used to produce a systemic effect or exert a mechanical effect to facilitate emptying the lower bowel Suppository bases: As with ointment bases, suppository base composition plays an important role in both the rate and extent of release of medications. Suppository base may be classified according to their composition and physical properties; 1. Oleaginous base 2. Water soluble or miscible base Tests of suppository bases

- 2. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 2 The specifications of suppository bases are mentioned below; 1.Melting range Since fats don’t have sharp melting point, their melting characteristics are expressed as a range indicating the temperature at which the fat start to melt and the temperature at which it is completely melted. 2. Solidification point This value indicates the time required for the base solidification when it is chilled in the mold. If the interval between the melting range and solidification point is 10 0 C or more, the time require for solidification may have to be shortened for more efficient manufacturing procedure by augmenting refrigeration. 3. Saponification value The number of milligrams of potassium hydroxide require to neutralize the free acids and to saponify the esters contained in 1 g of fat is an indication of the type of glyceride (mono or tri) as well as the amount of glyceride present. 4. Iodine value The value expresses the number of grams of iodine that react with 100 g of fat or other unsaturated material. The possibility of the decomposition by moisture, acid, or oxygen (leads to rancidity in fats) increases with high iodine values. 5. Water number The amount of water in grams which can be incorporated in 100 gram of fat is expressed by this value. The water number can be increased by addition of surface-active agents (surfactants). 6. Acid value The number of milligrams of potassium hydroxide required to neutralize the free acid in 1 gram of substance is expressed by this value. Low acid values or complete absence of acid are important for good suppository base. Free acids complicate formulation work, because they react with other ingredients and can also cause irritation when in contact with mucous membranes. Types of suppositories:

- 3. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 3 Quality control test for suppository Stability considerations in dispensing practice for suppositories include observations on excessive softening and oil stains on packaging. Compounded suppositories can be checked for calculations of actual or theoretical weight, and weight variation, shape, color, hardness, surface texture, and overall appearance. Suppository quality control includes physical and chemical aspects of the product. • Physical analysis includes visual examination (physical appearance), uniformity of weight, uniformity of texture, melting point, liquefaction time, melting and solidification time and mechanical strength. • Chemical analysis includes analysis of the activity and dissolution testing. The uniformity of texture can be accessed by sectioning a suppository longitudinally and laterally and ensuring that each section presents a smooth uniform surface PHYSICAL ANALYSIS 1.VISUAL EXAMINATION: Visual evaluation of suppositories is necessary and important to check for the absence of fissuring, pitting, fat blooming, exudation, sedimentation and migration of active ingredient. Suppositories can be observed as intact unit and also by splitting them longitudinally. The use of color chats is advisable. I. Shape It is advisable to check the shape of the suppository to see if it is consistent, irrespective of whether the suppository is ogive or torpedo shape. Suppositories must be of proper shape and size because change in shape affects the suppositories. Change in shape can affect the formulation II. Surface conditions The following can be checked; brilliance, dullness, mottling, cracks, dark regions, axial cavities, bursts, air bubble, holes etc. III. Stability Check the stability there should be no crack and bubbles in the suppositories. IV. Color The intensity, nature and homogeneity of the color should be verified. The use of color chart is advisable V. Odor Verification of order can prevent confusion when similar suppositories are being processed. Must be of desired odour because change in odour indicate the degradation process. 2. WEIGHT UNIFORMITY Procedure: 1. Weigh 20 suppositories individually. w1, w2, w3…. w20 2. Weigh all the suppositories together 3. Calculate the average weight = W/20. Limit: Not more than 2 suppositories differ from the average weight by more than 5%, and no suppository differs from the average weight by more than 10%

- 4. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 4 NOTE • If the weight is found to be too small, it is advisable to check whether the mold is being well filled and whether there are axial cavities or air bubbles caused by badly adjusted mechanical stirring or the presence of an undesirable surfactant. • If the weight is found to be too high, check that scraping has been carried out correctly, and also that the mixture is homogeneous 3. Melting range test (melting point, melting zone, macro-melting range test) Melting range or melting zone is the term often preferred by some rather than melting point. Many suppositories and medicated suppositories are mixtures and so don’t have a precise melting point. Routinely though we continue to call the physical phenomenon obtained under rigorous conditions the melting point. The release rate of the suppository is related to its melting point. It is therefore critical that this test be evaluated using a non-destructive method. Techniques: • A number of different techniques are used to study melting behavior including the open capillary tube, U- tube and the drop point method. One shortcoming is the use of limited data to describe the continuous complex melting process occurring in successive steps including various molecular weight triglycerides polymers or other ingredients. The methods used are similar in principle but include different steps and techniques. • In general, they include the set-up of the equipment placement of the suppository dosage unit in the apparatus followed by the application of heat and observation for a change in the system such as melting or movement. The results obtained using different methods don’t always agree so it is important to use a consistent method. In general, the melting point should be equal to or less than 37 0 C. • A nondestructive method must be used because if the suppository is melted before a measurement is made the suppository constituents may be transformed into a metastable state. The melting test consist of placing a suppository on the surface of water thermostatically controlled at 37oC and verifying the complete melting of the suppository in the few minutes. Melting point determination The determination methods are discussed below; 1) The use of U – shaped capillary tube to determine the melting point provides precise information for excipient control and consistency in production for those suppositories containing soluble active principals. The method is not suitable when the suppositories have a high powder content, which prevents the fat from sliding inside the capillary tube to give the end point determination. 2) When there are more numerous controls and where studies with a greater precision can be undertaken, an apparatus can be used consisting of microscope, a heated deck and a recorder. This provides for a more detailed observation and recording of the melting process. 3) The melting point can also be determined by placing a small diameter wire into the mold containing the suppository melt before the form solidifies. The form is then immersed in water held by the wire and the temperature of the liquid is raised slowly (about 1oC every 2 – 3 minutes) until the suppository slips of the wire, this is the melting point of the suppository.

- 5. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 5

- 6. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 6 4. Breaking Test (Hardness test) Purpose: This test applied to suppositories and passeries based on fatty excipients. It is not suited to suppositories and passeries based on hydrophilic excipients such as gelatin-glycerol mixture. Hardness indicates the maximum force which the suppository can withstand during storage, packaging and hardening. This test is design to check: Hardness Fragility Brittleness Apparatus A thermostated chamber closed in front by a glass window and containing a device that is to hold the suppository or passery. Two opposite jaws, the upper jaw descending vertically toward the lower jaw. The crushing surfaces of the jaw are flat perpendicular, to the direction of movement and larger than zone of contact with the suppository or passery. A plastic sample holder is fixed in the center of the jaw (half a holder in each jaw). The upper jaw (top pressure block) is connected to suspension to which can be added each of which weight 200g. The initial mass of the device is 600g. Crushing of the sample is carried out by successive adding 200g disc to the initial mass of 600g. Procedure 1. The suppository is placed in the instrument. 2. Add 600 g; leave it for one min. (use a stop watch). 3. If not broken, add 200 g every one min. until the suppository is broken. Calculations: The hardness of the suppository is calculated by adding the weights together. if the suppository is broken before the end of the last min. the last weight is canceled Limit: 1.8- 2kg 5. Liquefaction time (Softening time test) “The conversion of solid or gas into liquid is called Liquefaction.” Liquefaction testing provides information on the behavior of a suppository when subjected to the maximum temperature of 37Co and pressure to release API. The test commonly used is Krowzynski’s method, which measure the time required for the suppository to liquefy under pressure similar to those found in the rectum (approx. 30g) in the presence of water at 37oC. In general, the liquefaction should take no longer than 30 minutes. Krowzynski’s method Apparatus I The apparatus consists of a 16 mm diameter glass tube, 235 mm long with an approximately 6 mm diameter reduction at the base. One end is blocked with a small rubber stopper to facilitate cleaning after use. A thermostat graduated in lengths of a centigrade is used. The tube and thermometer are held in place by means of a large rubber stopper with two holes in a 225 mm long tube with a 50 mm diameter, filled with lateral tubes to allow the water at 37oC from a constant temperature water bath to circulate. Apparatus II Another apparatus equipped with a 30g glass stem 180mm long and 9mm wide. The base has a ring form with a 14mm diameter. The ring of the stem has a cuneiform shape opening to allow the melted excipient to escape upwards during the test. At a distance of approximately 100mm from the ring, three glass projections supports the stem in a vertical position in a tube.

- 7. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 7 The stem is also marked with a dash corresponding to its position with respect to the upper level of the tube Procedure 1. Obtain a constant temperature in the circulating water bath at 37oC. 2. Pour approx. 5ml of water down the tube so that all the tube is filled below the narrowed part (and so that the suppository to be tested is relatively humid conditions similar to those in the rectum. 3. After 5 minutes (the time necessary to bring the 5ml of water at 37oC) insert the suppository with the end pointed downward into the glass tube, insert the glass stem so that it is resting on top of the suppository and start the timer. 4. Note the time required for the mark of the glass stem to drop and come in line of the upper edge of the tube. 5. Repeat it for two more suppositories. 6. If the difference among the three times readings is greater than 105 seconds start again on two more suppositories (making a total of 5 suppositories. 7. Determine the average liquefaction time. Apparatus III (CellophaneTube method) Apparatus using a cellophane bag consist of a glass cylinder with an external diameter of 50mm narrowing down to 22mm at either end for a length of 30mm. Procedure 1. The cylinder is filled with two connections through which water that is maintained at 37oC can circulate in such a manner that the lower half of cellophane collapse and upper part widen. 2. A 34 – 35 cm length of cellulose dialyzer tubing, size inflated diameter of 1.12 inch (2.8cm) is moistened, opened and placed in the cylinder. 3. The tube is drawn out of either end of the cylinder and secured with two elastic bands. 4. Tubing is attached to allow the warm water to circulate maintaining the temperature. 5. As a result of water pressure the upper part of the tubing widens and the lower half collapse exerting pressure on suppository. 6... When the appropriate temperature is reached, the suppository is placed in the dialysis tubing and the time of liquefaction is measured.

- 8. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 8 The apparatus can also be used to measure the melting point of suppositories made with both water soluble and water insoluble bases. This can be accomplished by increasing the temperature of the water at a set rate. For example; one degree every 10 minutes until the suppository melts. 6.Melting and solidification time There is a relation between melting and solidification time that is important to characterize. The release of the API from the vehicle is related to the melting point of the vehicle and the solubility of the drug in the vehicle. Suppositories undergo three changes in phase during their “life.” i) First, they are melted ii) Secondly, they are solidified iii) Third they are again melted An understanding of these factors and their relationships is critical for evaluating the bioavailability of the final suppository formulation. Melting and solidification is a complex process and difficulties in measurements can arise leading to different results obtained using different methods. The higher the melting point the later the drug effects appear. If too high the effect of the drug will not appear. Solidification time is defined as the highest temperature occurring during the solidification of a supercooled liquid. a) Various methods are available to measure it including Shukoff’s method, in which the liquid is shaken in an evacuated flask until turbid and the temperature noted at which a transitory rise in temperature occurs during cooling b) The European pharmacopoeia also describes a procedure that involves heating the material, then allowing it to cool slowly while stirring. The temperature is recorded at 1-minute intervals. The cooling curve normally passes through a minimum which indicates a supercooled melt. Heat is liberated during crystallization and the temperature time curve rises. The maximum in this phase is the solidification temperature Thermometer Suppositories Dialyzing tube Glass cylinder Water inlet Collapsed part Widen part

- 9. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 9 7. Disintegration test for suppositories and pessaries The disintegration test determines whether the suppositories or pessaries soften or disintegrate within the prescribed time when placed in a liquid medium in the experimental conditions described below; Disintegration is considered to be achieved when; a) Dissolution is complete b) The components of the suppository or pessary have separated; melted fatty substance collect on the surface of the liquid, insoluble powder fall on the bottom and soluble components may be distributed in one or more of these ways. c) There is softening of the sample that may be accomplished by appreciable change of shape without complete separation of the components, the softening is such that the suppository or pessary no longer has a solid core offering resistance to pressure of a glass rod. d) Rupture of the gelatin shell of rectal or vaginal capsule occurs allowing release of the contents. e) No residue remains on the perforated disc or if a residue remains, it consists only of a soft or frothy mass having no solid core offering resistance to pressure of a glass rod (vaginal tablets). Apparatus Dimensions: The apparatus consists of a cylinder of glass or suitable transparent plastic of appropriate thickness. To the interior of which is attached by means of three hooks a metal device consisting of two perforated stainless metal discs each containing 39 holes, 4mm in diameter. The diameter of the disc is similar to that of the interior of the cylinder; the discs are about 30mm apart. Consist of 60mm long and 52 mm diameter cylinder of glass. Metal device 2 perforated metal disc HOOK Glass cylinder

- 10. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 10 Methodology: The test is carried out using three such apparatuses each containing a single sample. Each apparatus is placed in a beaker with a capacity of at least 4 liters filled with water maintained at 36oC – 37oC unless otherwise prescribed. The apparatus may also be placed together in a vessel with a capacity of at least 12 liters. The beaker is fitted with a slow stirrer and a device that will hold the cylinders vertically not less than 90 mm below the surface of the water and allow them to be inverted without emerging from the water. Acceptance criteria: Fat base = 30 mins Water soluble base= 60 mins Procedure 1. Use three suppositories or passries 2. Place each one on the lower disc of a device place the latter in the cylinder and secure 3. Invert the apparatuses every 10 minutes. 4. Examine the samples after the period prescribed in the monograph. 5. T0 pass the test all the samples must have disintegrated. Method of operation for vaginal tablets Use the apparatus described above, arranged so as to rest on the hooks. Procedure 1. Place it in a beaker of suitable diameter containing water maintained at 37oC with a level just below the upper perforated disc. 2. Using a pipette, adjust the level with the water at 37oC until a uniform film covers the perforations of the disc. 3. Use three vaginal tablets. 4. Place each one on the upper plate of an apparatus and cover the latter with a glass plate to maintain appropriate conditions of humidity. 5. Examine the state of the sample after the period prescribed in the monograph. 6. To pass the test all the samples must have disintegrated 8. Penetration time A suppository penetration test can be used to determine the temperature at which the suppository becomes sufficiently soft for a penetrating rod to drop through its length. Apparatus The apparatus used is shown;

- 11. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 11 Procedure 1. The temperature is adjusted to that required for the test generally about, 37oC. 2. The suppository is placed in the device and the penetration rod gently moved into place. 3. The devise holding the suppository and penetration rod is lowered into the constant temperature bath and a stopwatch is started. 4. When the penetration rod drops through the softened suppository, the time is recorded. CHEMICAL ANALYSIS 1. Dissolution testing One of the most important quality control tools available for in vitro assessment is dissolution testing. Purpose: Dissolution testing is often required for suppositories to test for hardening and polymorphic transitions of active ingredients and suppository bases. However, unlike for tablets and capsule dosage forms, there are not enough dissolution testing methods or validations for suppositories. This can be partly attributable to the immiscibility of some of the suppository vehicles in water. Dissolution testing methods include the paddle method, basket method, membrane diffusion, Suppository penetration apparatus. method/dialysis method, and the continuous flow/bead method.

- 12. QUALITY CONTROL OF SUPPOSITORIES CHAPTER NO 4 HASNAT TARIQ (GDIP) 12 2. STABILITY TESTING • Cocoa butter suppositories on storage, “bloom”; i.e., they form a white powdery deposit on the surface. This can be avoided by storing the suppositories at uniform cool temperatures and by wrapping them in foils. • Fat based suppository harden on storage • There is an upward shift in melting range due to slow crystallization to the more stable polymeric forms of the base. • The softening time test and differential scanning calorimetry can be used as stability indicating test methods. if we store the suppositories at an elevated temperature, just below its melting range, immediately after manufacture, the aging process is speeded 3. Assay of Active ingredient Determine the amount of active ingredient by the method prescribed in the assay; calculate, if necessary, the amount of active ingredient in the suppositories taken for the assay and divide by the no of suppositories. The result lies within the range for the content of active ingredient stated in the monograph.